Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Excavator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

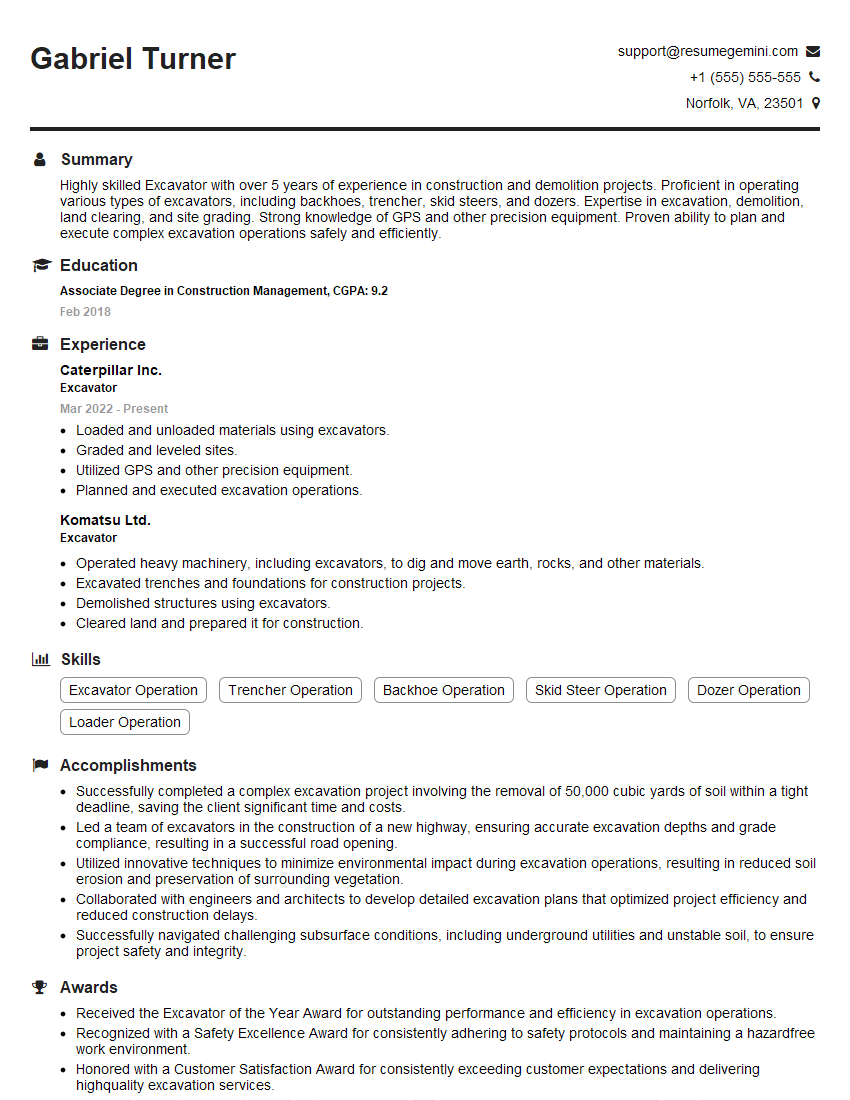

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Excavator

1. Explain the different types of excavators and their uses?

- Mini Excavators: Used for small-scale projects with limited space, such as landscaping, trenching, and backyard excavations.

- Tracked Excavators: Ideal for challenging terrain and stability on uneven surfaces, commonly used in construction and mining.

- Wheeled Excavators: Provide mobility and versatility for urban environments and road projects, allowing for quick repositioning.

- Long Reach Excavators: Designed for deep excavations, demolition, and reaching under structures, offering extended reach capabilities.

- Amphibious Excavators: Specialized machines capable of operating in both land and water environments, suitable for dredging, wetland construction, and disaster relief.

2. Describe the key components of an excavator and their functions?

Hydraulic System

- Powers the excavator’s movements and controls the hydraulic cylinders and motors.

- Consists of pumps, valves, hoses, and cylinders that transmit hydraulic fluid to power the machine.

Engine

- Provides the power source for the hydraulic system and other components.

- Typically diesel-powered, delivering torque and horsepower to operate the excavator efficiently.

Undercarriage

- Provides support and stability for the excavator.

- Consists of tracks or wheels, which determine the excavator’s mobility and terrain capabilities.

Arm and Boom

- The arm and boom extend and retract to position the bucket for digging.

- Controlled by hydraulic cylinders, allowing for precise manipulation and reach.

Bucket

- The primary attachment used for digging, trenching, and loading materials.

- Comes in various sizes and styles, depending on the application and soil conditions.

3. Explain the safety precautions and regulations that must be followed when operating an excavator?

- Wear appropriate safety gear, including hard hat, safety glasses, gloves, and high-visibility clothing.

- Conduct a thorough pre-operation inspection to ensure the excavator is in good working order.

- Maintain a clear and unobstructed work area, free from bystanders and potential hazards.

- Follow established weight limits and avoid overloading the excavator to prevent stability issues.

- Be aware of overhead power lines and other obstacles to prevent contact and accidents.

- Never leave the excavator unattended while it is running.

- Receive proper training and certification from qualified instructors to ensure safe operation.

- Comply with all applicable local, state, and federal safety regulations and standards.

4. Describe the maintenance procedures that should be performed on an excavator to keep it in good working condition?

- Check fluid levels (oil, hydraulic fluid, coolant)

- Inspect for leaks and any signs of damage

- Grease all lubrication points

- Inspect belts, hoses, and filters for wear and tear

- Clean the radiator and air filters

- Change engine oil and filter

- Replace hydraulic filters

- Inspect and adjust tracks or wheels

- Perform any necessary repairs or replacements as recommended by the manufacturer

Daily Checks

Weekly/Monthly Checks

Scheduled Maintenance

5. Explain how you would troubleshoot common problems that may occur while operating an excavator?

- Check fuel levels, fuel filters, and air filters

- Inspect spark plugs or glow plugs

- Check hydraulic fluid levels

- Inspect hoses and fittings for leaks

- Test hydraulic cylinders and motors

- Check battery connections

- Inspect wiring and fuses

- Test electrical components, such as lights and gauges

- Inspect tracks or wheels for damage

- Check undercarriage components

- Test arm and boom movements

Engine Problems

Hydraulic Problems

Electrical Problems

Mechanical Problems

6. Describe the different digging techniques used for different soil conditions?

- Conventional Digging: Used for loose and soft soils, involves pushing the bucket into the ground and curling it to lift the material.

- Ripping: Used for hard and compacted soils, involves using a ripper attachment to break up the soil before digging.

- Trenching: Used for creating narrow and deep trenches, involves using a narrow bucket and precise arm movements.

- Grading: Used for leveling surfaces and creating slopes, involves using a wide bucket to smooth and contour the soil.

- Backfilling: Used to fill in trenches or excavations, involves using the bucket to place and compact the material.

7. Explain how to safely transport an excavator on a trailer?

- Use an appropriately sized trailer that can handle the weight and dimensions of the excavator.

- Secure the excavator to the trailer using chains or straps, ensuring it is stable and cannot move during transport.

- Lower the boom and arm to reduce the overall height and prevent damage to overhead obstacles.

- Cover any exposed hydraulic hoses or electrical wires to protect them from damage.

- Check and adjust tire pressure on both the excavator and trailer to ensure a smooth and safe ride.

8. Describe the different types of attachments that can be used with an excavator and their applications?

- Buckets: Available in various sizes and shapes for digging, trenching, grading, and backfilling.

- Rippers: Used to break up hard and compacted soils, making them easier to excavate.

- Thumbs: Provide additional grip and versatility for handling objects, such as pipes and debris.

- Hydraulic Breakers: Used to break concrete, asphalt, and other hard materials.

- Augers: Used for drilling holes in the ground for foundations, fence posts, and utility poles.

9. Explain how to calculate the swing radius of an excavator?

The swing radius is the distance from the center of rotation (the pivot point) to the outermost point of the excavator, typically measured in feet or meters.

- Identify the pivot point, which is usually located at the base of the excavator.

- Measure the distance from the pivot point to the outermost point of the excavator, including the boom, arm, and bucket.

Formula:

Swing Radius = Distance from Pivot Point to Outermost Point10. Describe your experience in working with different types of excavation equipment and how it has prepared you for this role?

- Highlight your previous experience with excavators of different sizes and capacities.

- Mention specific projects where you utilized various excavation techniques and attachments.

- Explain how your experience has developed your skills in operating excavators safely and efficiently.

- Emphasize your ability to work in challenging conditions and meet project requirements.

- Discuss any certifications or training programs you have completed to enhance your knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Excavator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Excavator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Excavator is a skilled operator responsible for the safe and efficient operation of excavating equipment at construction sites. Their primary duty is to dig, trench, and move earth and other materials to prepare the ground for construction activities.

1. Equipment Operation

Excavator operators are proficient in operating various types of excavating equipment, including hydraulic excavators, backhoes, and trackhoes. They must possess the ability to maneuver these machines precisely and safely, ensuring accuracy in digging and material handling.

- Control excavation equipment, such as hydraulic excavators, backhoes, and trackhoes

- Excavate trenches, foundations, and other structures according to specifications

- Load and unload materials, such as dirt, rock, and debris

2. Site Preparation

In preparation for construction, excavators clear and level land, remove vegetation, and dig foundation trenches. They must adhere to site plans and ensure that the excavation meets the required dimensions and depths.

- Clear and level land for construction projects

- Remove vegetation and obstacles from construction sites

- Dig foundation trenches and other excavations according to blueprints

3. Material Handling

Excavator operators handle a variety of materials, including soil, rock, debris, and construction materials. They load and unload these materials using the excavator’s bucket or other attachments, ensuring efficient and safe movement.

- Load and unload materials using the excavator’s bucket or other attachments

- Transport materials around the construction site

- Place materials in designated areas or containers

4. Safety and Maintenance

Excavator operators prioritize safety on the construction site, following established protocols and wearing appropriate safety gear. They also conduct routine maintenance and inspections on their equipment to ensure optimal performance and prevent accidents.

- Follow safety protocols and wear appropriate safety gear

- Inspect and maintain excavation equipment regularly

- Report any equipment malfunctions or safety hazards

Interview Tips

Preparing for an Excavator interview requires thorough research about the position and the company. By showcasing your skills, experience, and enthusiasm for the role, you can increase your chances of impressing the interviewer.

1. Research the Company and Position

Before the interview, invest time in researching the company’s background, values, and recent projects. Understand the specific requirements of the Excavator role and how your qualifications align with them. By demonstrating your knowledge about the company and the position, you convey a genuine interest and commitment.

- Visit the company’s website to learn about their history, mission, and services.

- Review the job description thoroughly to identify the key responsibilities and qualifications.

- Search for news articles or industry publications that mention the company’s recent projects or initiatives.

2. Highlight Your Skills and Experience

During the interview, confidently present your skills and experience that are relevant to the Excavator role. Quantify your accomplishments whenever possible to demonstrate the impact of your work. Use specific examples to illustrate your proficiency in operating excavation equipment, managing materials, and adhering to safety protocols.

- Emphasize your experience in operating hydraulic excavators, backhoes, or trackhoes.

- Describe your ability to read and interpret blueprints and site plans accurately.

- Share examples of successful projects where you managed large volumes of materials efficiently.

3. Showcase Your Safety and Maintenance Knowledge

Safety is paramount in the construction industry. In your interview, demonstrate your understanding of safety protocols and your commitment to maintaining a safe work environment. Explain your experience in conducting regular equipment inspections and reporting any potential hazards. By emphasizing your safety consciousness, you assure the interviewer that you prioritize the well-being of yourself and your colleagues.

- Discuss your adherence to established safety protocols and the use of appropriate safety gear.

- Describe your knowledge of common excavation hazards and the steps you take to mitigate them.

- Explain your experience in performing routine maintenance and inspections on excavation equipment.

4. Ask Thoughtful Questions

Towards the end of the interview, asking thoughtful questions demonstrates your engagement and interest in the role and the company. Prepare questions that are specific to the position or the industry. By asking insightful questions, you not only show that you are inquisitive but also that you are eager to learn and contribute to the organization.

- Ask about the company’s plans for future projects or initiatives.

- Inquire about the opportunities for professional development and training within the organization.

- Seek clarification on any aspect of the job responsibilities or the company culture that you may have.

Next Step:

Now that you’re armed with the knowledge of Excavator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Excavator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini