Are you gearing up for an interview for a Extractive Metallurgist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Extractive Metallurgist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

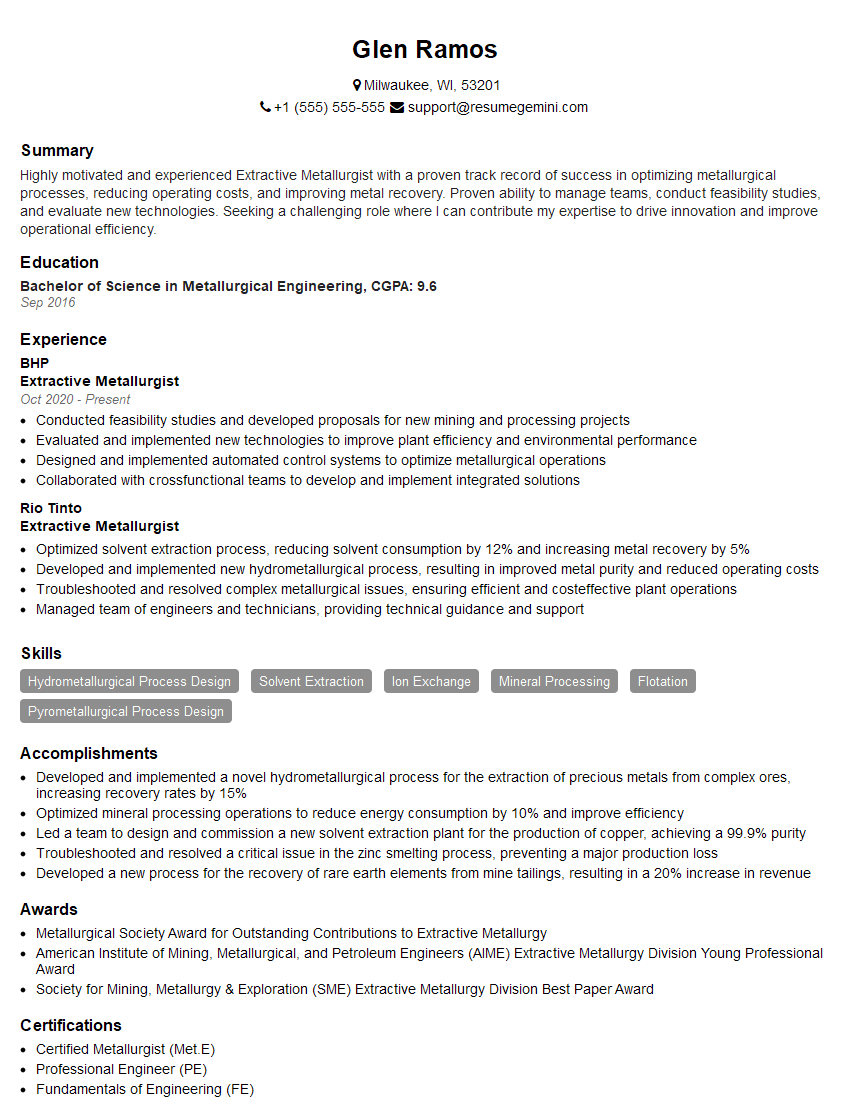

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extractive Metallurgist

1. Describe the role of thermodynamics in extractive metallurgy, and give an example of how it is applied in a real-world process.

Thermodynamics plays a crucial role in extractive metallurgy by providing the fundamental principles governing the behavior of chemical reactions and phase transformations. It allows us to predict and control the conditions necessary for the efficient extraction and processing of metals.

- Example: In the blast furnace process, thermodynamics is used to determine the optimum temperature and oxygen supply for maximizing iron production while minimizing fuel consumption.

2. Explain the principles and process of flotation, and discuss the factors that influence its effectiveness.

Froth Properties

- Bubble size and stability

- Froth height and drainage

Particle Characteristics

- Particle size and shape

- Surface properties (hydrophobicity/hydrophilicity)

Reagents

- Collectors

- Frothers

- pH modifiers

Process Conditions

- Temperature

- Aeration rate

- Impeller speed

3. Discuss the different types of hydrometallurgical processes and their applications in the extraction of metals.

- Solvent extraction: Selective extraction of metal ions from a liquid solution using an organic solvent.

- Precipitation: Removing metal ions from a solution by forming an insoluble precipitate.

- Ion exchange: Exchanging ions between a solid resin and a liquid solution.

- Electrowinning: Reducing metal ions in a solution to form a solid metal.

4. Describe the structure and properties of a typical slag, and explain its role in a metallurgical process.

Slag is a molten mixture of oxides and other inorganic compounds that forms during the smelting or refining of metals.

- Structure: Typically consists of a glassy matrix with crystalline phases dispersed throughout.

- Properties: Low melting point, low viscosity, immiscibility with molten metal.

- Role: Protects the metal from oxidation, absorbs impurities, promotes phase separation, and facilitates metal flow.

5. Explain the concept of phase diagrams and their importance in understanding the behavior of metals and alloys.

- Phase diagrams are graphical representations of the different phases that can exist in a system under varying conditions of temperature, pressure, and composition.

- They provide valuable information about the melting, freezing, and transformation temperatures of metals and alloys.

- Phase diagrams are crucial for predicting the microstructure and properties of materials.

6. Discuss the principles and limitations of pyrometallurgical processes, and provide examples of their applications in the extraction of metals.

- Principles: High-temperature processing involving chemical reactions in the presence of heat.

- Limitations: Energy-intensive, environmental concerns (emissions), potential for metal losses.

- Examples: Blast furnace, electric arc furnace, oxygen converter.

7. Explain the role of computational thermodynamics in optimizing extractive metallurgical processes.

- Computational thermodynamics uses software to model and simulate metallurgical processes.

- It allows for the prediction of phase equilibria, reaction rates, and other important parameters.

- By optimizing process parameters, computational thermodynamics helps improve efficiency, reduce costs, and enhance product quality.

8. Discuss the challenges and opportunities associated with the development of sustainable extractive metallurgical processes.

Challenges

- Reducing environmental impact (emissions, waste generation)

- Conserving energy and resources

- Minimizing water usage

Opportunities

- Developing innovative technologies (e.g., biohydrometallurgy, electrometallurgy)

- Utilizing renewable energy sources

- Recovery of valuable byproducts

9. Describe the latest advancements in extractive metallurgy, and discuss their potential impact on the industry.

- Artificial intelligence: Optimizing processes, predicting outcomes

- Sensor technology: Real-time monitoring, process control

- Advanced materials: Corrosion-resistant linings, high-temperature alloys

10. Explain how you would approach solving a real-world problem related to extractive metallurgy.

- Define the problem: Clearly understand the issue and its context.

- Gather data: Collect relevant information from various sources.

- Analyze data: Identify patterns, trends, and potential solutions.

- Develop solutions: Generate and evaluate multiple solutions.

- Implement and monitor: Put the solution into practice and track its effectiveness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extractive Metallurgist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extractive Metallurgist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Extractive Metallurgists are responsible for developing and implementing processes to extract metals from ores and minerals. They conduct research, design experiments, and operate metallurgical equipment to optimize extraction efficiency and minimize environmental impact. Key responsibilities include:

1. Ore Characterization and Processing

Analyze ore samples to determine their composition and properties.

- Design and implement comminution processes (crushing, grinding, and screening) to prepare ores for extraction.

- Develop methods to separate and concentrate valuable minerals from gangue materials.

2. Extraction Process Development

Evaluate and select appropriate extraction methods (e.g., flotation, leaching, solvent extraction) based on ore characteristics and metal value.

- Design and optimize extraction processes to maximize metal recovery and minimize reagent consumption.

- Monitor and control extraction operations to ensure optimal performance and efficiency.

3. Environmental Management

Assess and mitigate the environmental impact of extractive processes.

- Develop strategies to minimize waste generation and emissions.

- Design and implement systems for wastewater treatment and waste disposal.

4. Plant Operation and Maintenance

Oversee the operation and maintenance of extractive metallurgical plants.

- Train and supervise plant operators.

- Troubleshoot and resolve technical issues that arise during plant operation.

Interview Tips

To ace an interview for an extractive metallurgist position, candidates should be well-prepared and demonstrate a strong understanding of the field. Here are some tips to help you prepare:

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. Understand their business goals, products, and technologies.

- Visit the company’s website and study their annual reports.

- Review industry publications and news articles to stay updated on the latest advancements in extractive metallurgy.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by researching and practicing your answers. Focus on highlighting your technical skills, experience, and how you can contribute to the company.

- Explain your understanding of the extractive metallurgy process.

- Describe a project where you successfully developed or optimized an extraction process.

3. Showcase Your Problem-Solving Abilities

In an interview, you will likely be asked situational or hypothetical questions to assess your problem-solving skills. Use the STAR method (Situation, Task, Action, Result) to clearly articulate your approach to solving problems.

- For example, you could discuss how you resolved an issue with low metal recovery in a leaching process.

- Emphasize your analytical thinking, creativity, and ability to find innovative solutions.

4. Highlight Your Communication and Teamwork Skills

Extractive metallurgists often work in teams and must be able to effectively communicate with engineers, technicians, and other stakeholders. Demonstrate your communication skills by providing clear and concise answers during the interview.

- Share an example of a technical presentation you gave.

- Highlight your ability to work effectively in a multidisciplinary team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Extractive Metallurgist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.