Are you gearing up for an interview for a Extractor and Wringer Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Extractor and Wringer Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

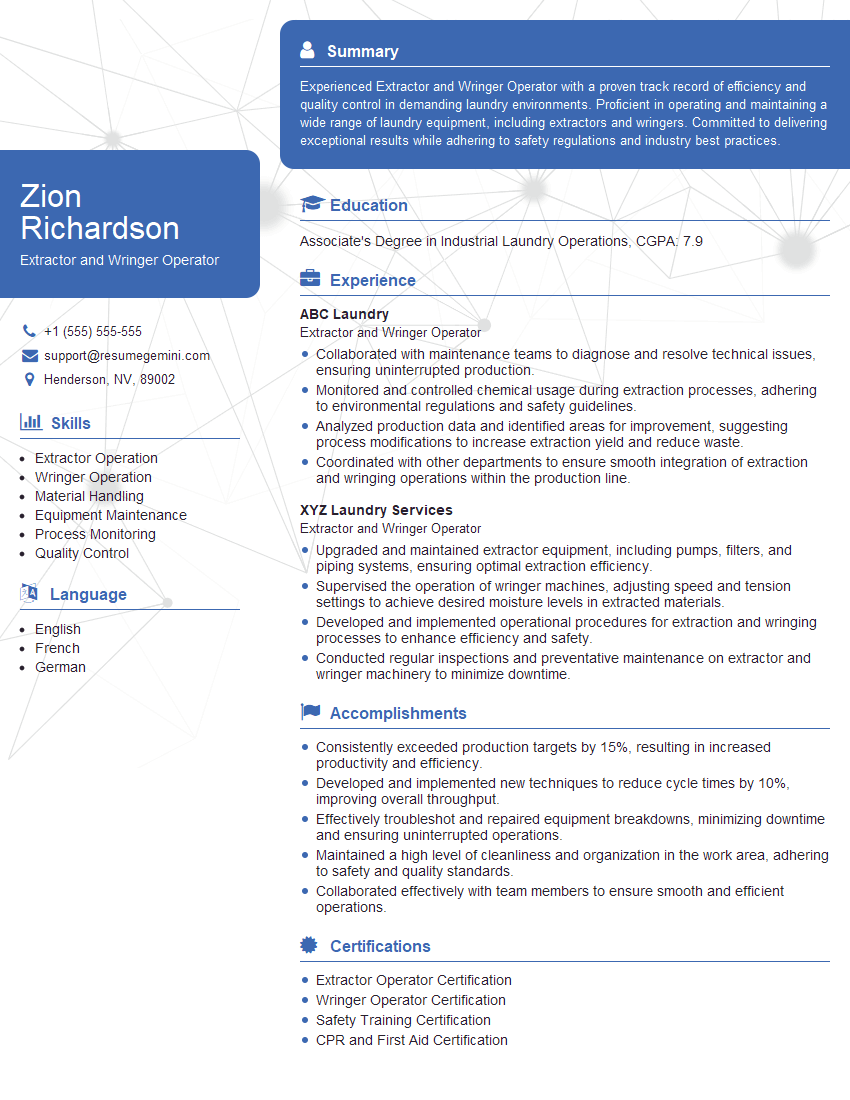

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extractor and Wringer Operator

1. What is the purpose of an extractor and wringer operator?

The primary purpose of an extractor and wringer operator is to ensure that textiles, garments, or other materials are thoroughly cleaned and dried.

2. What are the key responsibilities of an extractor and wringer operator?

- Operate and maintain extractors and wringers to remove excess water from textiles, garments, or other materials.

- Monitor the extraction and wringing process to ensure that materials are properly cleaned and dried.

- Unload and load materials into extractors and wringers, ensuring that they are evenly distributed for optimal results.

3. What are the safety precautions that should be followed when operating extractors and wringers?

- Ensure that the equipment is properly grounded and that all electrical connections are secure.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against exposure to chemicals and water.

- Never attempt to operate the equipment while it is in motion, and always follow the manufacturer’s instructions for safe operation.

4. How do you troubleshoot common problems that may occur with extractors and wringers?

- If the extractor or wringer is not extracting or wringing properly, check the power supply and ensure that all connections are secure.

- Check the water supply and ensure that the hoses are not kinked or blocked.

- If the materials are not being extracted or wrung evenly, adjust the settings of the equipment according to the manufacturer’s instructions.

5. What are the different types of extractors and wringers available?

- Basket extractors: These extractors use a perforated basket that spins rapidly to remove water from materials.

- Centrifugal extractors: These extractors use a rotating drum to generate centrifugal force, which forces water out of materials.

- Wringers: These machines use two rollers that squeeze materials to remove water.

6. What are the factors that affect the efficiency of extractors and wringers?

- The type of material being processed.

- The size and weight of the load.

- The speed and duration of the extraction or wringing process.

- The temperature of the water.

7. How do you maintain extractors and wringers to ensure optimal performance?

- Regularly clean and inspect the equipment for any signs of wear or damage.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Calibrate the equipment regularly to ensure accurate operation.

8. What are the environmental considerations that should be taken into account when operating extractors and wringers?

- Use environmentally friendly detergents and cleaning agents.

- Dispose of wastewater in accordance with local regulations.

- Conserve water by using efficient extraction and wringing techniques.

9. What are the career advancement opportunities for extractor and wringer operators?

- With experience and additional training, extractor and wringer operators can advance to supervisory positions.

- They may also be able to move into related fields, such as laundry management or textile production.

10. Why are you interested in this position as an extractor and wringer operator?

- I have always been interested in working in the laundry industry.

- I am eager to learn more about the operation and maintenance of extractors and wringers.

- I am a hard worker and I am confident that I can be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extractor and Wringer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extractor and Wringer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Extractor and Wringer Operator plays a crucial role in ensuring the hygiene and appearance of laundry items in commercial settings such as hotels, hospitals, and laundromats. The key job responsibilities of an Extractor and Wringer Operator include:

1. Loading and Unloading Laundry

Loading soiled laundry items into the extractor and unloading extracted items into the wringer.

- Verifying that laundry items meet processing requirements and separating items as necessary.

- Ensuring that the extractor and wringer are loaded to optimal capacity for efficient operation.

2. Operating Extractor and Wringer Machines

Operating the extractor and wringer machines safely and efficiently to remove excess water from laundry items.

- Setting and monitoring machine controls to ensure proper extraction and wringing cycles.

- Troubleshooting and resolving minor machine malfunctions to minimize downtime.

3. Inspecting and Sorting Extracted Laundry

Inspecting extracted laundry for any remaining moisture or damage and sorting items into appropriate categories.

- Identifying items that require additional processing or repair.

- Sorting laundry based on fabric type, color, or other criteria for further processing.

4. Maintaining a Clean and Safe Work Area

Maintaining a clean and organized work area to ensure the efficient operation of the laundry facility.

- Cleaning and sanitizing equipment and work surfaces regularly.

- Following safety protocols to minimize the risk of accidents or injuries.

Interview Tips

Preparing for an interview for an Extractor and Wringer Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s profile, including its industry, size, and reputation. Research the specific position you are applying for and understand the key responsibilities and requirements.

- Check the company’s website, social media pages, and industry publications.

- Review the job description thoroughly and identify the essential skills and experience required.

2. Practice Common Interview Questions

Anticipate common interview questions related to your technical skills, work experience, and soft skills. Prepare thoughtful answers that highlight your abilities and demonstrate your enthusiasm for the role.

- Describe your experience operating and maintaining laundry equipment.

- Explain how you prioritize tasks and manage your time effectively.

- Share an example of how you resolved a problem or improved efficiency in a previous role.

3. Emphasize Safety and Attention to Detail

As an Extractor and Wringer Operator, safety and attention to detail are paramount. Highlight your commitment to following safety protocols and your meticulous approach to handling laundry items.

- Discuss your understanding of workplace safety regulations and your experience following them.

- Explain how you ensure the accuracy and completeness of your work, especially when sorting and inspecting laundry.

4. Show Your Willingness to Learn and Grow

The laundry industry is constantly evolving with new technologies and best practices. Express your eagerness to learn and adapt to changes in the field.

- Ask questions about the company’s training opportunities and professional development programs.

- Share examples of your past experiences where you took initiative to improve your skills or knowledge.

5. Be Enthusiastic and Professional

During the interview, maintain a positive and enthusiastic demeanor. Demonstrate your interest in the position and your ability to work effectively within a team.

- Express your excitement about the opportunity to contribute to the company.

- Be respectful and professional in your interactions with the interviewers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Extractor and Wringer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!