Are you gearing up for a career in Extruder Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Extruder Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

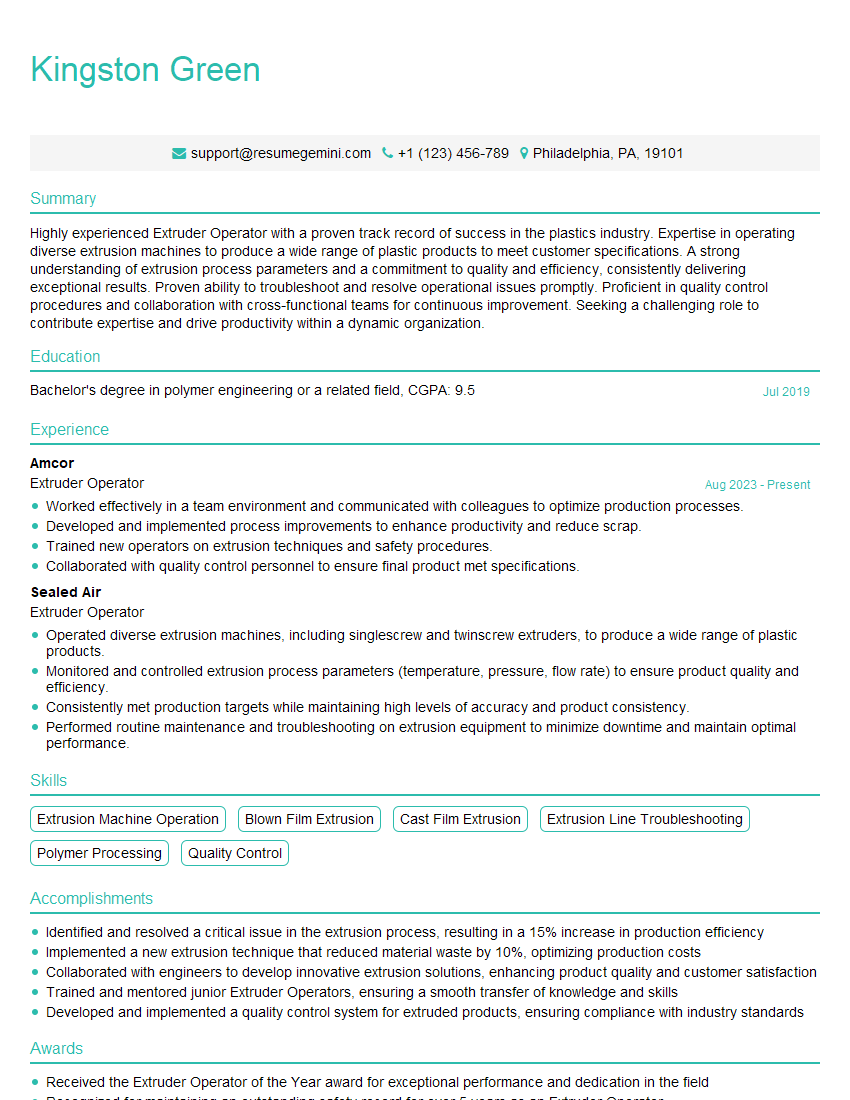

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extruder Operator

1. What are the key responsibilities of an Extruder Operator?

As an Extruder Operator, my main responsibilities include:

- Operating and monitoring extrusion machines to produce plastic or metal products according to specifications.

- Performing quality control checks on extruded products to ensure they meet required standards.

- Maintaining and troubleshooting extrusion equipment to minimize downtime and maximize production efficiency.

- Following safety protocols and adhering to established operating procedures.

2. Describe the different types of extruders and their applications.

Extrusion Blow Molders

- Used to produce hollow plastic products such as bottles, containers, and toys.

Extrusion Coating Systems

- Used to apply a coating of plastic or metal onto substrates such as paper, fabric, and wire.

Extrusion Laminators

- Used to bond multiple layers of different materials together to create composite products.

Extrusion Cast Film Lines

- Used to produce plastic films for applications such as packaging, agriculture, and construction.

3. What are the common challenges faced by Extruder Operators and how do you overcome them?

Some common challenges I have encountered as an Extruder Operator include:

- Material inconsistencies: Raw materials can vary slightly in properties, affecting the extrusion process. I overcome this by closely monitoring the material flow and adjusting machine settings as needed.

- Equipment malfunctions: Extruders are complex machines that can experience occasional breakdowns. I am trained to troubleshoot and resolve common issues, minimizing downtime.

- Quality control issues: Maintaining product quality is crucial. I conduct regular inspections and make adjustments to the extrusion process to ensure products meet specifications.

4. What are the safety precautions that must be taken when operating an extruder?

Safety is paramount in extrusion operations. I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection.

- Maintaining a clean and organized work area to prevent tripping hazards.

- Never operating an extruder without proper training and authorization.

- Following lockout/tagout procedures during maintenance and repairs.

- Being aware of the location of emergency stop buttons and evacuation routes.

5. What are the key performance indicators (KPIs) used to measure the effectiveness of an Extruder Operator?

- Production output: Meeting or exceeding production targets while maintaining quality standards.

- Downtime minimization: Keeping the extrusion line running smoothly to maximize productivity.

- Product quality: Producing products that consistently meet customer specifications and industry standards.

- Material waste reduction: Optimizing the extrusion process to minimize scrap and waste.

- Safety compliance: Maintaining a safe work environment and adhering to established safety protocols.

6. How do you stay updated with the latest advancements in extrusion technology?

To stay abreast of the latest developments in extrusion technology, I engage in the following practices:

- Attending industry conferences and webinars.

- Reading technical journals and white papers.

- Consulting with equipment manufacturers and industry experts.

- Participating in training programs and workshops.

- Seeking opportunities to collaborate with other Extruder Operators and explore innovative solutions.

7. Describe your experience with troubleshooting and resolving issues related to extrusion equipment.

During my time as an Extruder Operator, I have encountered and resolved various equipment-related issues, including:

- Screw and barrel wear: I inspect and replace worn components as needed to prevent production disruptions.

- Temperature control issues: I monitor and adjust temperature settings to ensure optimal product quality and minimize defects.

- Motor and drive problems: I troubleshoot and repair electrical and mechanical issues to maintain machine functionality.

- Hydraulic system leaks: I locate and seal leaks to prevent downtime and ensure safe operation.

8. What is the role of quality control in the extrusion process, and how do you ensure the quality of extruded products?

Quality control is vital in extrusion operations. I play a crucial role in ensuring product quality by:

- Monitoring product dimensions: I use measuring devices to verify that products meet specified tolerances.

- Inspecting for defects: I visually inspect products for any imperfections or inconsistencies.

- Testing physical properties: I conduct tests to assess the strength, durability, and other properties of extruded products.

- Maintaining records: I keep detailed records of quality control checks and product specifications.

9. Describe your experience in working as part of a team in an extrusion manufacturing environment.

In previous extrusion operations, I have consistently worked effectively as part of a team. My contributions include:

- Collaborating with colleagues: I communicate regularly with other operators and supervisors to coordinate production and resolve issues.

- Sharing knowledge and expertise: I share my knowledge and experience with team members to enhance overall productivity.

- Supporting others: I am always willing to assist my coworkers and provide support when needed.

- Maintaining a positive work environment: I contribute to a positive and collaborative team atmosphere.

10. Why are you interested in this Extruder Operator position with our company?

I am eager to join your company as an Extruder Operator for several reasons:

- Company reputation: Your company is well-respected in the industry for its commitment to quality and innovation.

- State-of-the-art facility: I am impressed by your company’s investment in advanced extrusion technology.

- Career growth opportunities: I believe that your company provides opportunities for professional development and career advancement.

- Alignment with my skills and experience: My skills and experience as an Extruder Operator align well with the requirements of this position.

- Contribution to the team: I am confident that I can make a significant contribution to your team’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extruder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extruder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Extruder Operators are responsible for operating and maintaining extruders, machines that convert plastic pellets into various shapes and forms. Their primary duties involve:

1. Extruder Operation

Setting up and operating extruders to produce plastic products, ensuring optimal production efficiency.

2. Equipment Monitoring

Continuously monitoring extruder performance, including temperature, pressure, and speed, and making adjustments as needed to maintain product quality.

3. Product Inspection

Inspecting produced plastic products for defects, ensuring they meet specifications and customer requirements.

4. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting procedures to keep extruders in good working condition, minimizing downtime and ensuring smooth operations.

Interview Tips

To effectively prepare for an Extruder Operator interview, consider the following tips:

1. Research the Company and Position

Thoroughly research the company, its industry, and the specific role to gain a comprehensive understanding of their operations and expectations.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to showcase your skills and experience that are directly relevant to the job requirements. Emphasize your proficiency in extruder operation, equipment monitoring, product inspection, and maintenance.

3. Demonstrate Technical Knowledge

Prepare for technical questions related to extruders, plastics, and production processes. Showcase your understanding of extruder principles, material properties, and quality control techniques.

4. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Prepare specific examples to demonstrate your abilities and enthusiasm for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Extruder Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!