Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Extruding Machine Operator/Setter/Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

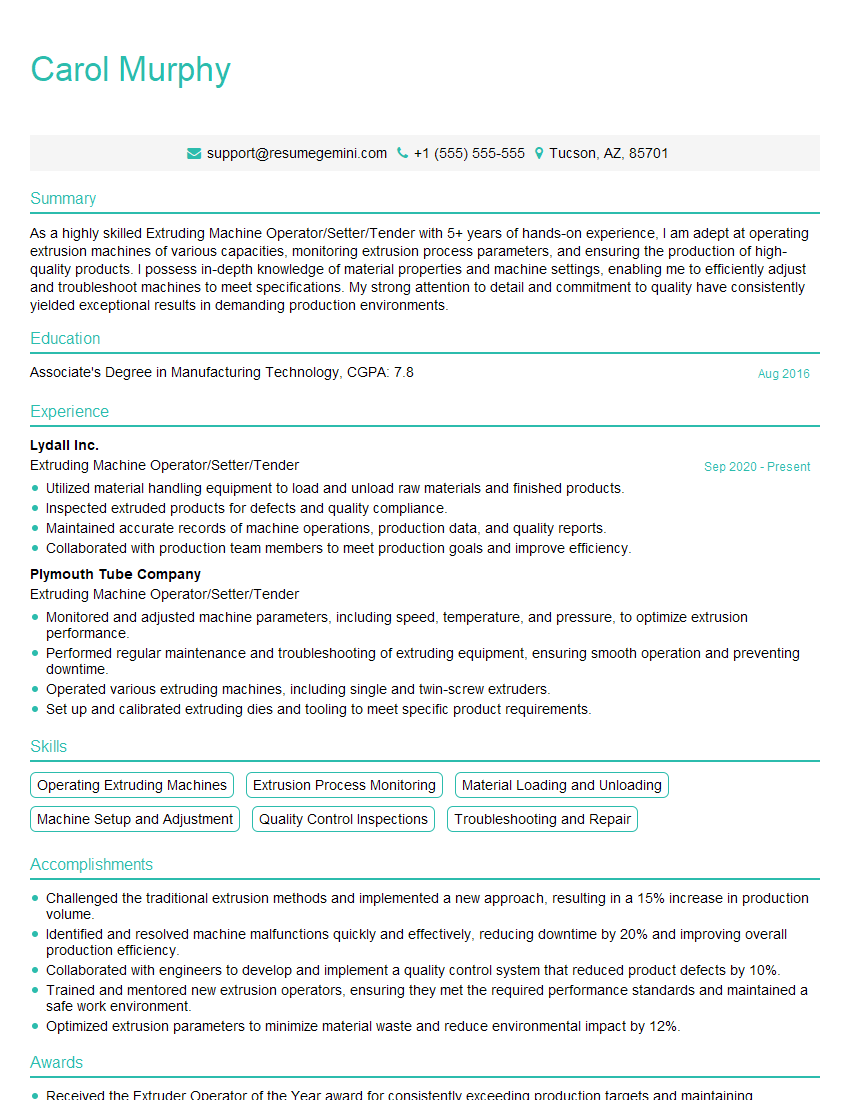

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extruding Machine Operator/Setter/Tender

1. Describe the steps involved in operating an extruding machine?

The steps involved in operating an extruding machine are as follows:

- Set up the extrusion machine according to the job specifications, including loading and aligning the raw material.

- Start the machine and monitor the extrusion process to ensure that the product meets the desired specifications.

- Make adjustments to the machine settings as needed to maintain product quality and meet production targets.

- Unload the extruded product and prepare it for further processing or storage.

- Clean and maintain the extrusion machine to ensure its optimal performance and longevity.

2. How do you troubleshoot common problems associated with extruding machines?

Troubleshooting Basic Machine Problems

- Check for any blockages or obstructions in the machine, such as clogged nozzles or worn-out parts.

- Inspect the raw material for any defects or inconsistencies that could affect the extrusion process.

- Review the machine settings to ensure that they are correct for the desired product specifications.

Troubleshooting Quality-Related Problems

- Identify the source of the quality issue, whether it is related to the raw material, machine settings, or environmental factors.

- Make necessary adjustments to the machine settings or process parameters to resolve the issue.

- Monitor the extrusion process closely to ensure that the desired product quality is achieved and maintained.

3. What is the role of the die in an extruding machine, and how do you maintain it?

The die in an extruding machine plays a crucial role in shaping the extruded product to the desired cross-sectional profile.

- Regularly inspect the die for any wear or damage that could affect the product quality.

- Clean the die thoroughly to remove any buildup of material or contaminants.

- Sharpen or replace the die as needed to maintain its optimal performance and prevent product defects.

4. How do you ensure the safety of yourself and others when working with extruding machines?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Follow all established safety protocols and procedures.

- Never reach into or touch the machine while it is running.

- Keep the work area clean and free of any potential hazards.

- Be aware of the potential risks and hazards associated with extruding machines and take appropriate precautions.

5. Explain the difference between hot and cold extrusion processes.

Hot Extrusion

- Involves heating the raw material to a high temperature to make it more workable.

- Produces stronger and more precise products with a smooth surface finish.

- Suitable for a wide range of materials, including metals, plastics, and ceramics.

Cold Extrusion

- Does not involve heating the raw material, which is typically softer.

- Produces products with good dimensional accuracy and surface finish.

- Limited to softer materials, such as aluminum, copper, and certain alloys.

6. How do you determine the appropriate screw speed for different extrusion processes?

The appropriate screw speed for different extrusion processes depends on various factors, including:

- The type of material being extruded

- The desired product specifications

- The size and design of the extruder

By considering these factors, the screw speed can be adjusted to optimize the extrusion process and achieve the desired product quality and output.

7. Describe the role of temperature control in extruding machines.

Temperature control in extruding machines is essential for ensuring product quality and process efficiency:

- Proper temperature control prevents the material from overheating, which can lead to degradation or poor product quality.

- It also ensures that the material remains sufficiently fluid to flow through the extruder and be shaped properly.

- Temperature control systems monitor and adjust the temperature of the extruder barrel and die to maintain optimal conditions for the extrusion process.

8. How do you calculate the extrusion pressure required for a specific material?

The extrusion pressure required for a specific material can be calculated using the following formula:

- P = (2 * S * L) / D

- Where:

- P is the extrusion pressure (in pascals)

- S is the shear strength of the material (in pascals)

- L is the length of the extrusion die (in meters)

- D is the diameter of the extrusion die (in meters)

By knowing the shear strength of the material and the dimensions of the extrusion die, the required extrusion pressure can be calculated.

9. Explain the purpose and function of a breaker plate in an extrusion machine.

A breaker plate in an extrusion machine serves several important functions:

- It helps to distribute the material evenly across the width of the die.

- It provides back pressure to the extruder screw, which aids in the melting and homogenization of the material.

- It helps to create a more consistent and uniform extrudate.

By properly designing and using a breaker plate, the quality and consistency of the extruded product can be significantly improved.

10. How do you adjust the die gap in an extrusion machine?

Adjusting the die gap in an extrusion machine involves the following steps:

- Loosen the die holder: Using appropriate tools, loosen the bolts or screws that hold the die holder in place.

- Adjust the die gap: Using a feeler gauge or other measuring device, adjust the distance between the die and the breaker plate to achieve the desired gap.

- Tighten the die holder: Once the die gap is set, tighten the bolts or screws to secure the die holder in place.

Properly adjusting the die gap is crucial for ensuring the production of high-quality extrudates with the desired dimensions and properties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extruding Machine Operator/Setter/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extruding Machine Operator/Setter/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Extruding Machine Operators/Setters/Tenders are responsible for operating, setting up, and maintaining extruding machines that produce various products, such as plastic pipes, wires, and films. Their primary duties include:

1. Machine Operation

Start, stop, and monitor extruding machines to produce products according to specifications.

- Adjust machine settings, such as temperature, pressure, and speed, to optimize production.

- Monitor product quality and make necessary adjustments to ensure it meets standards.

2. Machine Setup

Prepare and set up extruding machines for different production runs.

- Install and change extrusion dies to create various product shapes and sizes.

- Clean and maintain machines to ensure smooth operation and prevent breakdowns.

3. Material Handling

Handle and prepare materials used in the extrusion process.

- Load raw materials, such as plastic pellets or powders, into the extruding machine.

- Unload and package finished products according to specifications.

4. Troubleshooting and Maintenance

Identify and resolve operational issues with extruding machines.

- Perform routine maintenance tasks, such as lubrication and cleaning, to keep machines in good working condition.

- Troubleshoot and repair minor machine malfunctions.

Interview Tips

Preparing thoroughly for an interview as an Extruding Machine Operator/Setter/Tender can significantly increase your chances of success. Consider the following tips to ace your interview:

1. Research the company and position

Learn about the company’s industry, products, and culture. Also, thoroughly review the job description to understand the specific responsibilities and qualifications required for the role.

- Visit the company’s website, read industry publications, and connect with employees on LinkedIn to gather information.

- Identify the key skills and experience highlighted in the job description and prepare examples to demonstrate your proficiency.

2. Practice answering common interview questions

Anticipate questions about your technical skills, experience operating extruding machines, and ability to troubleshoot and resolve issues. Practice your responses to provide clear and concise answers that showcase your capabilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work experience.

- Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

3. Highlight your safety awareness and attention to detail

Emphasize your commitment to safety and your ability to work meticulously in a manufacturing environment. Share examples of your safety practices and explain how you ensure the quality of your work.

- Describe your understanding of relevant safety protocols and how you adhere to them in your daily work.

- Provide examples of how your attention to detail has helped you identify and resolve potential issues before they become significant problems.

4. Ask thoughtful questions

Asking well-prepared questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that show you have researched the company and are genuinely interested in the role.

- Inquire about the company’s future plans and how the position fits into those plans.

- Ask about opportunities for professional development and growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Extruding Machine Operator/Setter/Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!