Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Extrusion Die Coordinator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

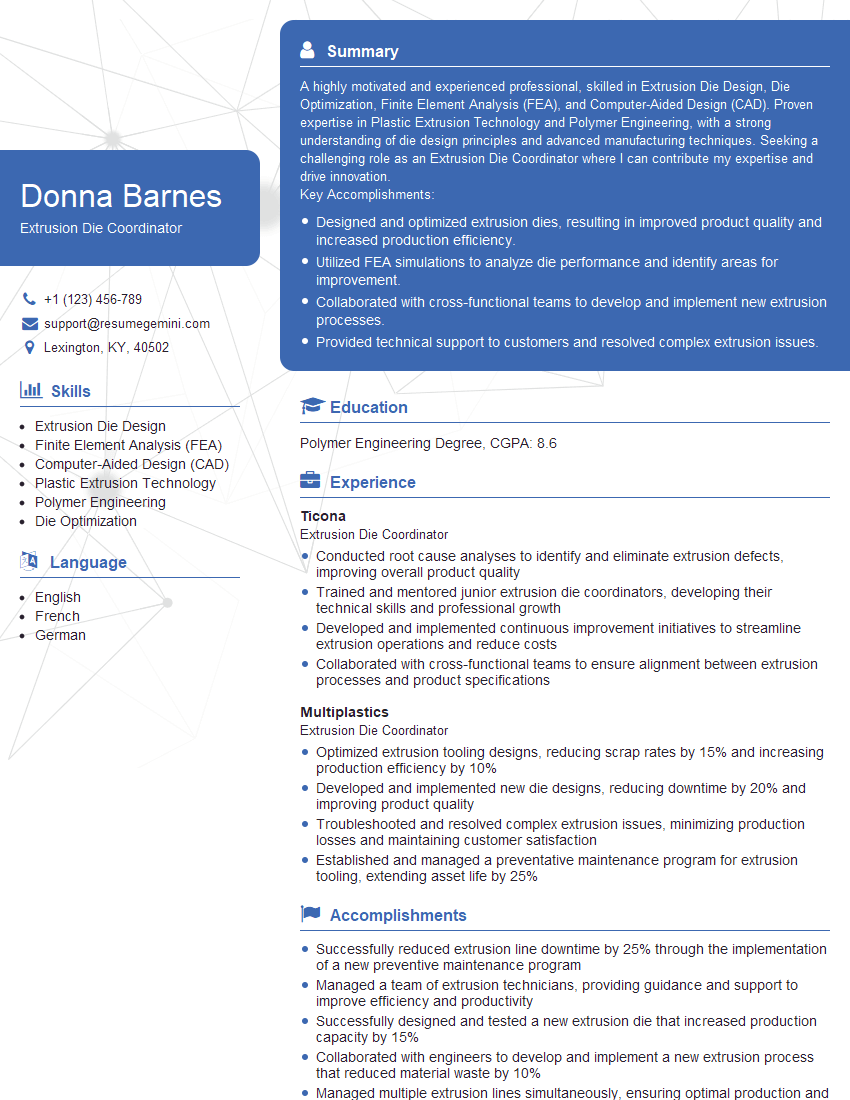

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Die Coordinator

1. What are the key responsibilities of an Extrusion Die Coordinator?

- Coordinate and oversee all aspects of extrusion die operations.

- Manage a team of extrusion die designers and engineers.

- Develop and implement new extrusion die designs to improve product quality and efficiency.

- Troubleshoot and resolve extrusion die problems.

- Maintain a safe and efficient work environment.

2. How do you ensure the quality of extrusion dies?

Quality Control

- Implement rigorous quality control procedures.

- Inspect dies for defects and ensure they meet specifications.

- Monitor die performance and make adjustments as needed.

- Collaborate with quality assurance team to identify and resolve quality issues.

Training and Development

- Provide training to die designers and engineers on quality standards.

- Emphasize the importance of defect prevention and root cause analysis.

- Encourage continuous improvement initiatives to enhance die quality.

3. What are the latest advancements in extrusion die technology?

- Additive manufacturing for rapid prototyping and complex designs.

- Simulation software for optimizing die performance and reducing trial and error.

- Advanced materials for improved durability and corrosion resistance.

- Automation and robotics for increased efficiency and precision.

- Data analytics for real-time monitoring and predictive maintenance.

4. How do you stay up to date with the latest industry trends and technologies?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Participate in online forums and webinars.

- Network with other professionals in the field.

- Pursue continuing education and certification programs.

5. What are the challenges you have faced as an Extrusion Die Coordinator?

- Meeting tight deadlines without compromising quality.

- Managing a diverse team with varying skill sets and experience levels.

- Troubleshooting complex die problems and finding innovative solutions.

- Balancing the demands of production with the need for ongoing research and development.

- Staying abreast of rapidly evolving industry standards and technologies.

6. How do you handle working under pressure and meeting deadlines?

- Prioritize tasks and allocate time effectively.

- Communicate regularly with team members and stakeholders.

- Identify potential bottlenecks and develop contingency plans.

- Delegate responsibilities and empower team members.

- Remain calm and focused under pressure.

7. What is your approach to continuous improvement?

- Establish clear goals and objectives.

- Collect and analyze data to identify areas for improvement.

- Develop and implement innovative solutions.

- Monitor progress and make adjustments as needed.

- Foster a culture of continuous learning and growth.

8. How do you manage conflict within your team?

- Create a respectful and open work environment.

- Encourage effective communication and active listening.

- Facilitate discussions and mediate disagreements.

- Seek common ground and identify win-win solutions.

- Provide constructive feedback and support team members in resolving conflicts.

9. What is your experience with extrusion die design software?

- Proficient in industry-leading die design software such as Siemens NX and CATIA.

- Utilize software tools for modeling, simulation, and analysis.

- Experience in optimizing die designs for specific product requirements.

- Familiar with advanced features such as parametric modeling and additive manufacturing integration.

- Able to create and modify die designs efficiently and accurately.

10. What are your strengths and weaknesses as an Extrusion Die Coordinator?

Strengths

- Expertise in extrusion die design and fabrication.

- Strong leadership and communication skills.

- Ability to manage complex projects and meet deadlines.

- Knowledge of industry trends and technologies.

- Passion for continuous improvement.

Weaknesses

- Limited experience in international manufacturing operations.

- Working on multiple projects simultaneously can be challenging.

- Tendency to be overly perfectionistic at times.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Die Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Die Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Extrusion Die Coordinator, your primary responsibilities will revolve around ensuring the efficient and effective operation of extrusion die systems.

1. Die Design and Development

Collaborate with design engineers to develop and refine extrusion die designs.

- Analyze extrusion requirements, product specifications, and material properties.

- Create and optimize die geometries using computer-aided design (CAD) software.

2. Die Fabrication and Assembly

Supervise the fabrication, assembly, and maintenance of extrusion dies.

- Inspect incoming materials and components for quality and accuracy.

- Assemble dies according to specifications and ensure their proper alignment and functioning.

3. Die Maintenance and Troubleshooting

Monitor and maintain extrusion dies to prevent downtime and ensure optimal performance.

- Conduct regular inspections and identify potential issues proactively.

- Troubleshoot die problems and implement corrective actions.

4. Process Optimization and Quality Control

Analyze extrusion processes and identify opportunities for improvement.

- Collaborate with production and quality control teams to optimize extrusion parameters.

- Monitor product quality, identify defects, and implement measures to mitigate them.

Interview Tips

Preparing for an interview as an Extrusion Die Coordinator requires a well-rounded approach. Here are some tips to help you ace the interview and showcase your capabilities.

1. Research the Company and Industry

Thoroughly research the company you’re applying to, their products, and the extrusion industry. Demonstrate your knowledge of the company’s strengths and challenges.

- Visit the company website, read industry publications, and attend trade shows.

- Be prepared to discuss your understanding of the company’s extrusion processes and products.

2. Highlight Your Technical Expertise

Extrusion die design and fabrication require a deep understanding of materials science, engineering principles, and manufacturing processes.

- Quantify your experience with CAD software, tool design, and die fabrication techniques.

- Use specific examples to demonstrate your problem-solving abilities in troubleshooting extrusion issues.

3. Emphasize Your Communication and Leadership Skills

Collaboration and communication are crucial in this role. Emphasize your ability to work effectively with design engineers, production teams, and quality control personnel.

- Highlight your experience in leading projects, coordinating with stakeholders, and providing technical guidance.

- Showcase your ability to resolve conflicts and foster a positive work environment.

4. Prepare for Competency-Based Questions

Interviewers often use competency-based questions to assess your skills and experience. Be prepared to answer questions about your ability to:

- Analyze extrusion requirements and optimize die designs.

- Troubleshoot die problems and implement effective solutions.

- Manage projects and collaborate with cross-functional teams.

5. Ask Thoughtful Questions

Asking well-informed questions shows your interest in the position and the company. Prepare questions about the company’s extrusion capabilities, current projects, and future plans.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Extrusion Die Coordinator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.