Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Extrusion Die Corrector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Extrusion Die Corrector so you can tailor your answers to impress potential employers.

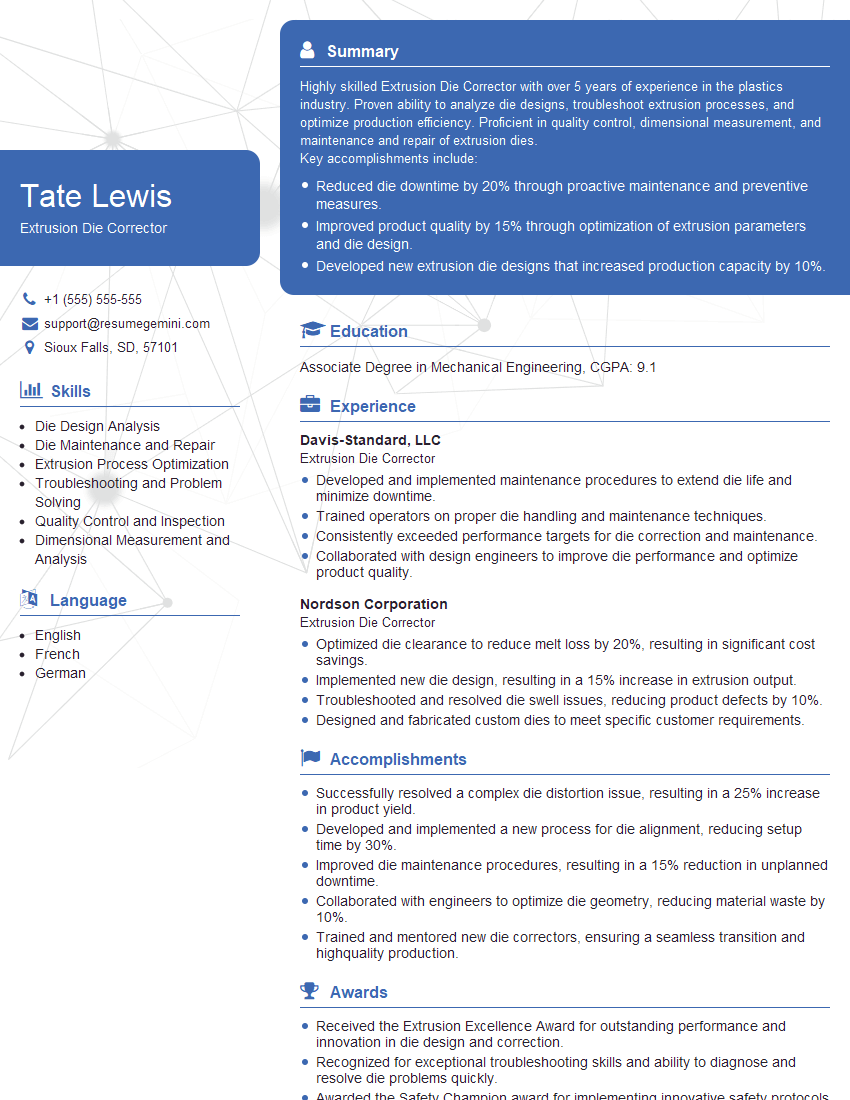

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Die Corrector

1. Can you explain the extrusion process and the role of an Extrusion Die Corrector?

The extrusion process involves forcing a molten material through a die to create a desired shape. The Extrusion Die Corrector plays a crucial role in ensuring the die’s accuracy and quality, maintaining the desired melt flow, and troubleshooting production issues.

- Monitor the extrusion process to identify irregularities and correct them

- Inspect dies for wear and damage, and perform necessary repairs or adjustments

- Calibrate and troubleshoot extrusion equipment to optimize production efficiency

2. What methods do you use to evaluate and adjust extrusion die profiles?

Profilometry

- Employ a profilometer to measure the die’s internal dimensions and identify deviations from specified tolerances

- Interpret the profilometry data and determine the necessary adjustments to achieve the desired profile

Flow Modeling Simulations

- Run flow modeling simulations to predict the material’s behavior within the die

- Analyze simulation results to identify potential flow imbalances or defects, and make corrections

3. How do you ensure the accuracy and consistency of extrusion dies?

To ensure accuracy and consistency, I follow these steps:

- Establish and maintain a comprehensive quality control system for die manufacturing and inspection

- Utilize precision measuring instruments to verify the accuracy of die dimensions and tolerances

- Conduct regular audits to ensure ongoing compliance with quality standards

4. What techniques do you employ to troubleshoot and resolve defects in extruded products?

Troubleshooting involves a systematic approach to identify the root cause of defects:

- Examine the extruded product to identify the type and location of the defect

- Inspect the extrusion equipment, including the die, to determine potential issues

- Analyze the extrusion parameters, such as temperature, pressure, and flow rates

5. How do you stay abreast of advancements in extrusion technology?

To stay current with industry advancements, I prioritize the following:

- Attend industry conferences and workshops to learn about new technologies and best practices

- Review technical literature and research papers to stay informed about the latest developments

- Network with other extrusion professionals to exchange knowledge and experiences

6. Can you describe your experience in optimizing extrusion processes to improve product quality and efficiency?

In my previous role, I implemented several optimization strategies that significantly improved product quality and efficiency:

- Improved die design to reduce pressure drop and material degradation

- Optimized extrusion parameters to minimize defects and maximize throughput

- Implemented a predictive maintenance program to prevent equipment failures and downtime

7. How do you handle conflicts or disagreements with colleagues or superiors during the design and fabrication of extrusion dies?

When faced with conflicts or disagreements, I prioritize these steps:

- Maintain open and respectful communication to understand different perspectives

- Present technical data and objective analysis to support my recommendations

- Collaborate with team members to develop mutually acceptable solutions

8. How would you approach the design of an extrusion die for a complex or novel material?

For complex or novel materials, I take the following approach:

- Thoroughly research the material’s properties and characteristics

- Conduct preliminary tests to determine the material’s behavior under extrusion conditions

- Collaborate with material scientists and engineers to optimize die design

9. What is your experience with using computer-aided design (CAD) software in the design of extrusion dies?

I am proficient in using CAD software such as AutoCAD and SolidWorks for the design and simulation of extrusion dies. I leverage these tools to:

- Create detailed 3D models of die components

- Perform flow simulations to analyze material flow and optimize die design

- Generate technical drawings and documentation for die manufacturing

10. What are your strengths and weaknesses as an Extrusion Die Corrector?

My strengths include:

- Strong technical knowledge in extrusion die design and fabrication

- Excellent problem-solving and analytical skills

- Proven ability to work effectively in a team environment

My areas for improvement include:

- Limited experience with some specialized extrusion technologies

- Working on developing my leadership skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Die Corrector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Die Corrector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Extrusion Die Corrector, you will play a pivotal role in ensuring the smooth and efficient operation of the extrusion process. Your key responsibilities will encompass:

1. Die Maintenance and Repair

Inspect and analyze extrusion dies for defects or damage, utilizing specialized equipment and techniques.

- Accurately identify and diagnose die problems, determining the root cause.

- Develop and implement effective repair solutions, using a comprehensive understanding of die design and materials.

2. Die Modification and Optimization

Collaborate with engineers and production teams to modify dies for improved performance or specific product requirements.

- Conduct thorough simulations and calculations to optimize die designs for increased productivity and product quality.

- Supervise the fabrication and installation of modified dies, ensuring precision and alignment.

3. Process Monitoring and Troubleshooting

Monitor extrusion processes closely, analyzing data and observing operations to identify potential issues.

- Troubleshoot and resolve process deviations, implementing corrective actions to maintain optimal production.

- Provide technical guidance to operators and maintenance personnel, ensuring adherence to procedures and best practices.

4. Continuous Improvement

Strive for continuous improvement in die maintenance and extrusion processes, seeking innovative solutions.

- Participate in research and development initiatives, exploring new techniques and materials for die optimization.

- Document and share best practices, fostering knowledge transfer and enhancing overall performance.

Interview Tips

To ace your interview as an Extrusion Die Corrector, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company’s operations, products, and the industry’s trends.

- Review the company’s website, industry publications, and relevant online resources.

- Identify specific examples of your work experience that align with the company’s needs.

2. Highlight Your Technical Expertise

Emphasize your knowledge of extrusion die design, materials, and manufacturing processes.

- Discuss your experience in troubleshooting and repairing complex dies, providing specific examples.

- Showcase your proficiency in utilizing specialized equipment and techniques for die analysis.

3. Quantify Your Accomplishments

Provide concrete examples of your contributions and the positive impact they had on productivity, quality, or cost.

- Quantify your results whenever possible, such as “Reduced die downtime by 25% through improved maintenance practices.”

- Explain how your efforts contributed to the overall success of the extrusion operation.

4. Emphasize Your Problem-Solving Abilities

Highlight your ability to identify, analyze, and resolve complex die-related problems.

- Describe a challenging situation you faced and the logical approach you took to find a solution.

- Explain how you collaborated with others to troubleshoot and overcome challenges.

5. Demonstrate Your Commitment to Continuous Improvement

Show that you are passionate about innovation and continuous improvement in the field.

- Share ideas for optimizing die designs or improving extrusion processes.

- Discuss your involvement in research or development projects related to extrusion technology.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Extrusion Die Corrector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Extrusion Die Corrector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.