Feeling lost in a sea of interview questions? Landed that dream interview for Extrusion Line Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Extrusion Line Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

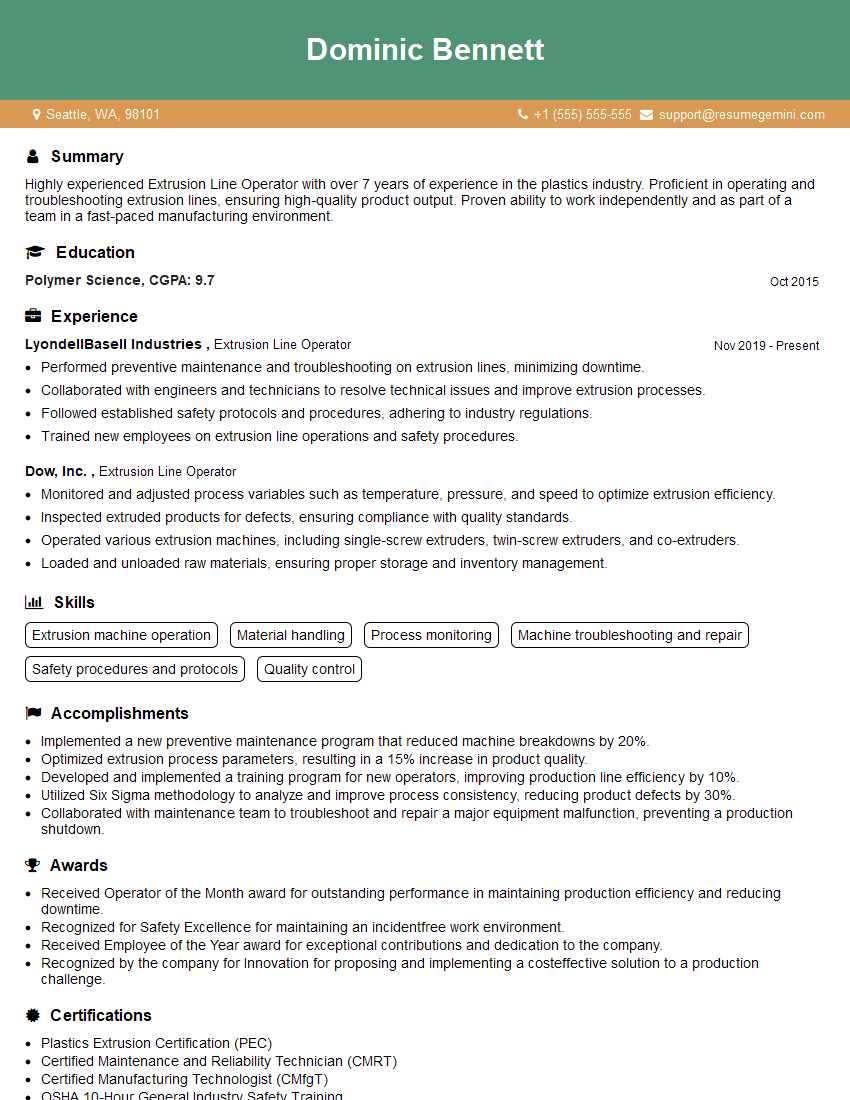

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Line Operator

1. Which parameters do you monitor and control during extrusion operations?

- Screw speed

- Melt pressure

- Melt temperature

- Die temperature

- Extruder load

- Amperage draw

- Back pressure

2. How do you troubleshoot common extrusion defects, such as gels, voids, or fish eyes?

Gel formation

- Overheating of the melt

- Excessive shear forces

- Contamination

Void formation

- Low melt pressure

- Poor material flow

- Entrapped air

Fish eyes

- Contamination with foreign materials

- Poor dispersion of pigments or additives

- Improper mixing

3. Describe the steps involved in performing a routine maintenance check on an extrusion line.

- Visual inspection of equipment

- Lubrication of moving parts

- Checking for signs of wear or damage

- Tightening of bolts and connections

- Cleaning of equipment

- Calibration of sensors and instruments

4. How do you ensure the quality of the extruded product meets specifications?

- Regular monitoring of process parameters

- Conducting in-process and final product testing

- Maintaining calibration records of measuring equipment

- Implementing quality control procedures

- Maintaining a clean and organized work area

5. What is the importance of preventive maintenance in extrusion operations?

- Reduces downtime and production losses

- Increases equipment lifespan and reliability

- Improves product quality and consistency

- Ensures safety and compliance with regulations

- Optimizes production efficiency

6. How do you handle safety precautions when operating an extrusion line?

- Wearing appropriate PPE

- Following established safety procedures

- Inspecting equipment regularly for potential hazards

- Being aware of surroundings

- Reporting any unsafe conditions or incidents

7. Describe the role of auxiliary equipment, such as chillers and granulators, in the extrusion process.

- Regulate melt temperature

- Prevent thermal degradation

- Control product dimensions

- Improve surface finish

- Convert extruded products into smaller pieces

- Facilitate packaging and handling

- Recycle scrap material

Chillers

Granulators

8. What types of materials are commonly processed in extrusion operations?

- Thermoplastics (e.g., polyethylene, polypropylene, PVC)

- Thermosets (e.g., epoxy, polyester, polyurethane)

- Elastomers (e.g., natural rubber, synthetic rubber)

- Composites (e.g., fiberglass-reinforced plastics, metal-filled polymers)

9. How do you optimize the extrusion process for different material types and product requirements?

- Adjusting process parameters (e.g., screw speed, melt temperature)

- Selecting appropriate tooling (e.g., dies, nozzles)

- Using additives and modifiers to enhance material properties

- Optimizing cooling and post-processing conditions

10. What are the key challenges and troubleshooting techniques in extrusion operations?

Challenges

- Melt stability

- Product quality consistency

- Equipment maintenance and downtime

Troubleshooting

- Identifying root causes of problems

- Analyzing data and process parameters

- Implementing corrective actions

- Monitoring process improvements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Line Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Line Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Extrusion Line Operator is responsible for overseeing the operation of machinery that converts raw materials into various plastic forms, typically in the form of shapes and profiles. It is a critical role that demands a comprehensive understanding of extrusion techniques and a keen eye for quality control. Let’s delve into the key responsibilities of this crucial position:

1. Equipment Operation

Setting up, operating, and maintaining extrusion lines, including extruders, dies, and auxiliary equipment. Ensuring optimal performance and productivity by monitoring and adjusting process parameters like temperature, pressure, and speed.

- Performing regular inspections, calibrations, and maintenance tasks to ensure smooth operation and minimize downtime.

2. Material Handling

Selecting, weighing, and preparing raw materials for extrusion. Monitoring material flow and adjusting feeder rates to ensure consistent product quality.

- Inspecting and sorting incoming materials, ensuring they meet specifications.

3. Quality Control

Adhering to established quality standards by monitoring and inspecting extruded products thoroughly. Identifying and rectifying defects promptly to maintain product integrity.

- Performing dimensional checks, visual inspections, and other quality tests to ensure products meet specifications.

4. Process Optimization

Collaborating with engineers and supervisors to identify areas for process improvement. Implementing modifications to enhance efficiency, reduce waste, and optimize line performance.

- Suggesting process improvements based on observation and knowledge of extrusion techniques.

5. Teamwork and Safety

Working effectively with team members to achieve production goals. Maintaining a clean and safe work environment, adhering to established safety protocols.

- Participating in training and development programs to stay updated on industry best practices.

Interview Preparation Tips

To effectively ace an interview for the Extrusion Line Operator position, meticulous preparation is crucial. The following interview preparation tips will enhance your chances of success:

1. Research the Company

Demonstrating knowledge of the company and its products showcases your interest and aligns your qualifications with the job requirements. Visit the company’s website, LinkedIn profile, and Glassdoor reviews to gather insights into their operations, culture, and industry reputation.

- Learn about the company’s history, mission, and values to demonstrate alignment with their objectives.

- Research the specific role and its responsibilities to ensure a thorough understanding of the expectations.

2. Highlight Relevant Experience

Prepare specific examples from your past experience that showcase your skills and abilities in extrusion operations. Emphasize your proficiency in operating extrusion lines, handling materials, and maintaining quality standards.

- Quantify your accomplishments using specific metrics whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing clear and concise responses.

3. Practice Behavioral Questions

Behavioral questions are commonly asked in interviews to assess your personality, work ethic, and problem-solving abilities. Prepare for these questions by recalling specific instances that demonstrate your skills and values.

- Common behavioral questions include: “Tell me about a time when you faced a challenging situation and how you overcame it.”

- Practice answering these questions clearly and concisely, focusing on the actions you took and the positive outcomes you achieved.

4. Prepare Industry-Specific Questions

Researching industry-specific questions demonstrates your enthusiasm for the field and shows that you have taken the time to understand the technical aspects of extrusion operations.

- Ask questions about the company’s extrusion techniques, the types of plastics they work with, and any recent advancements in the industry.

- This demonstrates your knowledge and eagerness to learn.

5. Dress Professionally and Arrive on Time

First impressions matter. Dressing professionally conveys respect for the interviewers and the company. Punctuality demonstrates your organization and time management skills.

- Choose attire that is clean, pressed, and appropriate for a manufacturing environment.

- Arrive at the interview venue a few minutes early to show your eagerness and professionalism.

By following these tips and thoroughly preparing for the interview, you can increase your chances of making a strong impression and securing the Extrusion Line Operator position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Extrusion Line Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.