Are you gearing up for a career in Extrusion Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Extrusion Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

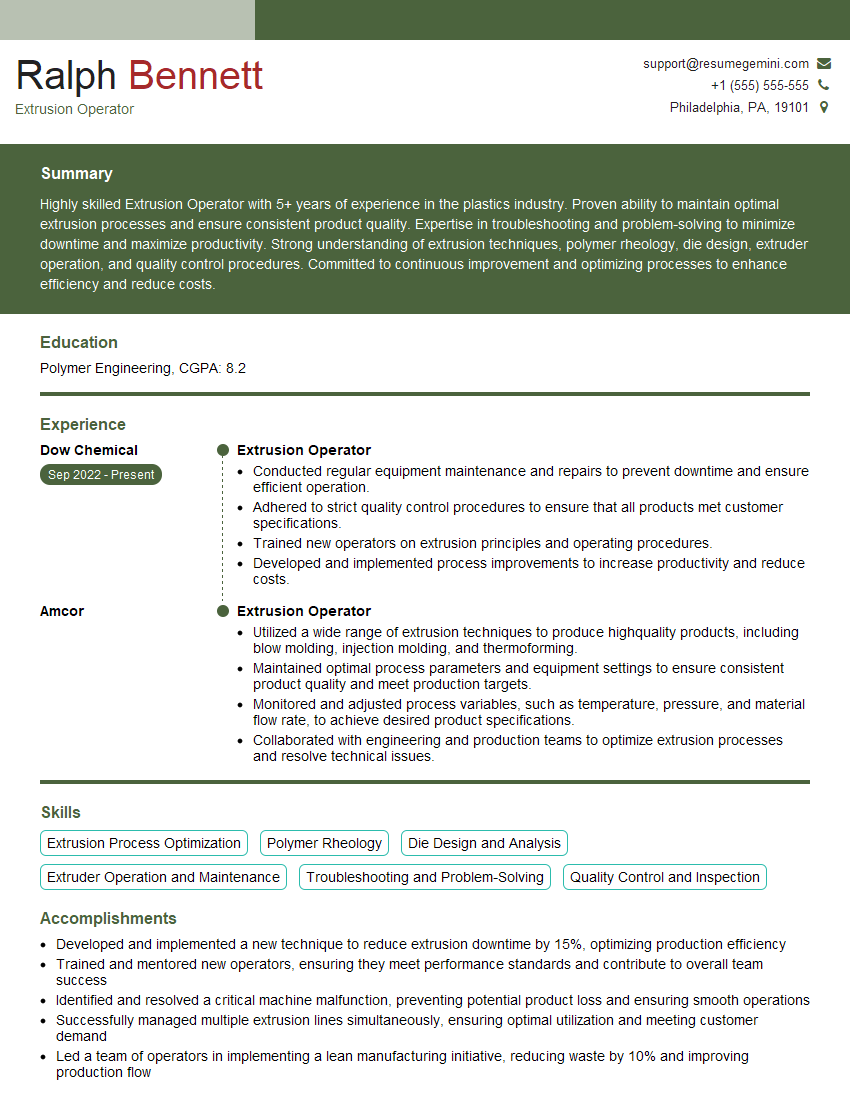

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Operator

1. Describe the key responsibilities of an Extrusion Operator?

In the role of an Extrusion Operator, my key responsibilities typically involve:

- Monitoring and controlling extrusion equipment to produce plastic or rubber products.

- Setting up and adjusting extrusion lines according to specified requirements.

2. Explain the different types of extrusion processes?

There are various types of extrusion processes, including:

- Blown film extrusion – Produces thin, flexible plastic films used in packaging.

- Sheet extrusion – Creates plastic sheets of various thicknesses for applications like thermoforming.

- Pipe extrusion – Produces plastic pipes for plumbing, drainage, and other industrial uses.

3. What are the common faults that can occur during extrusion and how would you troubleshoot them?

Extrusion processes can experience various faults, such as:

- Die swell – Excess material buildup at the die opening, causing dimensional variations.

- Sharkskin – Irregular surface texture on the extruded product due to melt instability.

- Gel formation – Unmelted or partially melted resin particles in the extrudate.

- Troubleshooting involves identifying the cause of the fault, adjusting process parameters (e.g., temperature, speed), and performing maintenance on equipment.

4. How do you ensure the quality of extruded products?

Quality control in extrusion involves:

- Visual inspection – Examining the product for defects like surface irregularities, color variations, and dimensional accuracy.

- Dimensional measurements – Using gauges or calipers to verify product dimensions meet specifications.

- Tensile testing – Measuring the material’s strength and elongation properties.

5. What are the safety precautions to be observed when operating extrusion equipment?

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Maintaining a clean and organized work area free of tripping hazards.

- Following lockout/tagout procedures when servicing equipment.

- Being aware of pinch points and rotating machinery.

6. How do you stay up-to-date with advancements in extrusion technology?

To stay current with industry developments, I:

- Attend industry conferences and workshops – Learn about new technologies, best practices, and industry trends.

- Read trade publications and technical journals – Stay informed about advancements in extrusion equipment and materials.

- Network with other professionals – Exchange knowledge and experiences with colleagues in the field.

7. What are your strengths and weaknesses as an Extrusion Operator?

My strengths include:

- Strong technical knowledge of extrusion processes and equipment.

- Excellent troubleshooting and problem-solving skills.

- Attention to detail and commitment to quality.

Areas for improvement include:

- Developing expertise in specialized extrusion techniques.

- Enhancing my supervisory and leadership skills.

8. How do you handle working under pressure and tight deadlines?

In high-pressure situations, I remain calm and focused by:

- Prioritizing tasks and managing my time effectively.

- Seeking support from colleagues or supervisors when needed.

- Breaking down large projects into smaller, manageable steps.

9. What motivates you to excel as an Extrusion Operator?

My motivation stems from:

- The satisfaction of producing high-quality products that meet customer specifications.

- The opportunity to continuously improve processes and optimize equipment performance.

- The challenge of solving complex technical problems.

10. How would you contribute to the success of our team?

As a team player, I would contribute by:

- Sharing my knowledge and expertise with colleagues.

- Collaborating on projects and supporting team goals.

- Identifying areas for improvement and suggesting solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Extrusion Operators play a crucial role in manufacturing processes by operating extrusion machinery and ensuring efficient production. Their key responsibilities include:

1. Operating Extrusion Equipment

Utilizing extrusion machines to produce various products by melting, shaping, and cooling materials.

- Calibrating and adjusting extrusion machines for optimal operation.

- Monitoring production lines to ensure smooth operation and product quality.

2. Material Handling

Preparing and loading raw materials into extrusion equipment.

- Monitoring material levels and ensuring timely replenishment.

- Cleaning and maintaining extrusion equipment to prevent contamination.

3. Quality Control

Monitoring and inspecting products during the extrusion process to ensure adherence to specifications.

- Identifying and correcting any deviations from quality standards.

- Maintaining accurate records of production and quality data.

4. Machine Maintenance

Performing routine maintenance and repairs on extrusion equipment to prevent breakdowns.

- Lubricating and inspecting machinery for potential issues.

- Troubleshooting and resolving minor equipment malfunctions.

Interview Tips

Interview preparation is essential for success in an Extrusion Operator interview. Here are some tips to consider:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Research the specific role and its responsibilities to demonstrate your interest and understanding.

- Check the company’s website, LinkedIn page, and industry news.

- Read through the job description carefully and note key requirements.

2. Practice Answering Common Interview Questions

Anticipate potential interview questions and prepare thoughtful answers. Focus on highlighting your relevant skills and experience.

- Prepare examples of your experience operating extrusion equipment.

- Describe your troubleshooting and problem-solving abilities.

3. Highlight Safety and Quality Consciousness

Emphasize your commitment to safety and maintaining high product quality. Extrusion processes involve handling hazardous materials and adhering to strict quality standards.

- Discuss your awareness of industry best practices and safety protocols.

- Provide examples of how you have ensured product quality in previous roles.

4. Demonstrate Mechanical Aptitude

Extrusion Operators require mechanical aptitude to maintain and troubleshoot equipment. Showcase your understanding of machinery components and basic repair skills.

- Discuss any experience with electrical or mechanical systems.

- Highlight your willingness to learn and troubleshoot complex machinery.

5. Prepare for Physical Demands

Extrusion Operators often work in physically demanding environments, requiring standing for extended periods and lifting heavy materials. Be prepared to discuss your physical abilities.

- Emphasize your physical fitness and ability to work in a fast-paced environment.

- Mention any experience with manual labor or heavy lifting.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Extrusion Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!