Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Extrusion Process Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

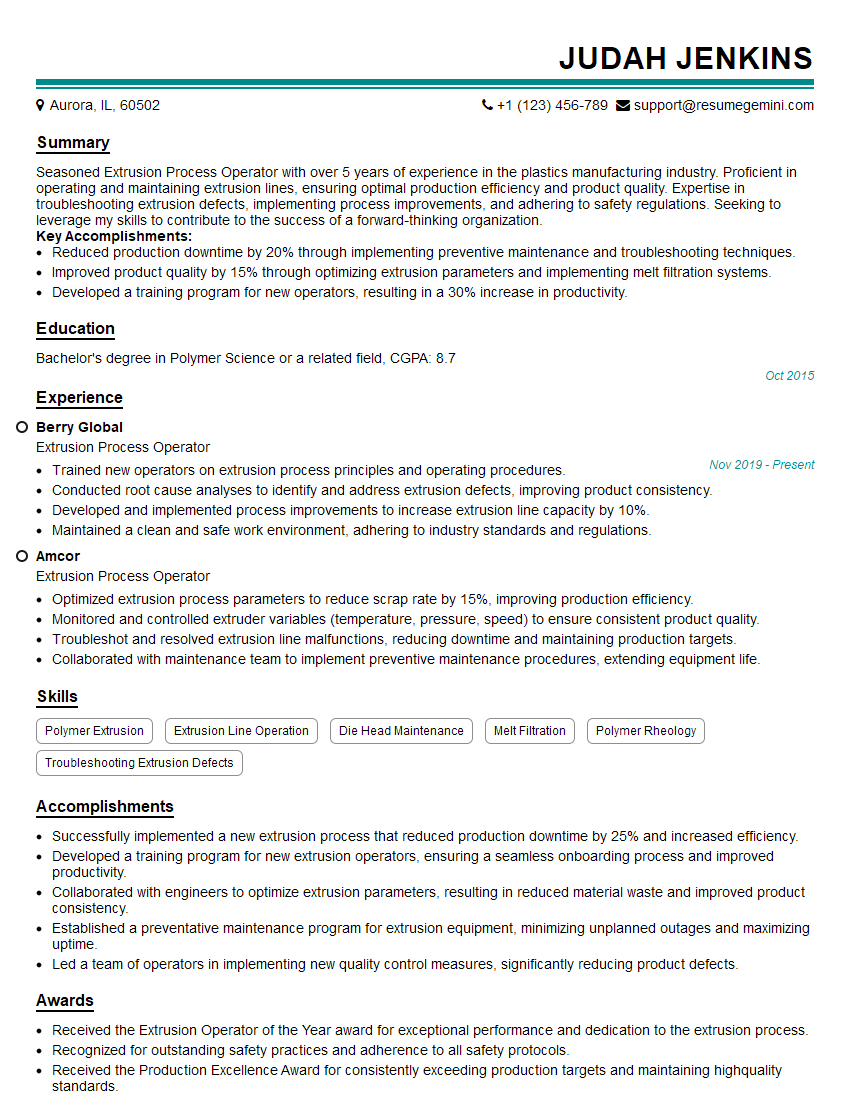

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Process Operator

1. Describe the key stages involved in the extrusion process?

The key stages involved in the extrusion process are:

- Mixing: The raw materials are mixed to create a uniform blend.

- Extrusion: The blended material is forced through a die to create the desired shape.

- Cooling: The extruded product is cooled to solidify it.

- Cutting: The cooled product is cut to the desired length.

- Packaging: The cut product is packaged for storage and shipment.

2. Explain the different types of extruders used in the extrusion process?

There are two main types of extruders used in the extrusion process:

Single-screw extruders

- Use a single screw to move the material through the extruder.

- Relatively simple and inexpensive to operate.

- Used for a wide range of materials, including plastics, rubber, and food.

Twin-screw extruders

- Use two screws that intermesh to move the material through the extruder.

- More complex and expensive to operate than single-screw extruders.

- Provide better mixing and dispersion of materials.

3. What are the critical process parameters that need to be monitored and controlled during the extrusion process?

The critical process parameters that need to be monitored and controlled during the extrusion process include:

- Temperature: The temperature of the material must be controlled to ensure proper melting and flow.

- Pressure: The pressure in the extruder must be controlled to ensure proper material flow and prevent damage to the equipment.

- Screw speed: The screw speed must be controlled to ensure proper mixing and material flow.

- Die temperature: The die temperature must be controlled to ensure proper product formation.

4. Describe the common defects that can occur during the extrusion process and how to troubleshoot them?

Common defects that can occur during the extrusion process include:

- Bubbles: Bubbles can be caused by entrapped air or moisture in the material.

- Warping: Warping can be caused by uneven cooling or improper material flow.

- Cracking: Cracking can be caused by excessive stress or improper material formulation.

- Orange peel: Orange peel is a surface defect that can be caused by improper die design or material flow.

5. Explain the role of the die in the extrusion process?

The die plays a critical role in the extrusion process by shaping the molten material into the desired product.

- The die must be designed to ensure proper flow of the material.

- The die must be made of a material that is resistant to wear and corrosion.

- The die must be regularly inspected and maintained to ensure optimal performance.

6. Describe the safety precautions that must be followed when operating an extruder?

The following safety precautions must be followed when operating an extruder:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Never operate an extruder that is not properly guarded.

- Never attempt to clear a jam in the extruder while it is running.

- Always follow the manufacturer’s instructions for operating the extruder.

7. Explain how to calculate the extrusion rate of an extruder?

The extrusion rate of an extruder can be calculated using the following formula:

Extrusion rate = (Screw speed * Displacement per revolution) / Density of the material

8. Describe the maintenance procedures that are required for an extruder?

The following maintenance procedures are required for an extruder:

- Regularly inspect the extruder for wear and tear.

- Clean the extruder regularly to remove any build-up of material.

- Lubricate the extruder according to the manufacturer’s instructions.

- Calibrate the extruder regularly to ensure accurate product dimensions.

9. Explain how to troubleshoot an extruder that is not producing the desired product?

To troubleshoot an extruder that is not producing the desired product, follow these steps:

- Check the extruder’s settings to ensure that they are correct.

- Inspect the extruder for any signs of wear or damage.

- Check the material to ensure that it is the correct type and grade.

- Calibrate the extruder to ensure accurate product dimensions.

10. Describe the quality control procedures that are used to ensure the quality of extruded products?

The following quality control procedures are used to ensure the quality of extruded products:

- Visual inspection of the products to identify any defects.

- Dimensional measurements to ensure that the products meet the specified tolerances.

- Mechanical testing to ensure that the products meet the required strength and durability requirements.

- Chemical testing to ensure that the products meet the specified material specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Process Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Process Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Extrusion Process Operator is responsible for overseeing and operating the extrusion process in a manufacturing setting. Their primary duties involve manipulating raw materials, calibrating equipment, and monitoring production lines to ensure the efficient production of extruded products.

1. Extrusion Line Operation

Operate and monitor extrusion lines, ensuring smooth production and adherence to quality standards.

- Start, stop, and adjust extrusion machines and auxiliary equipment.

- Control material flow, temperature, and pressure throughout the extrusion process.

2. Material Handling

Handle and prepare raw materials, ensuring they meet specifications and are properly loaded into the extrusion equipment.

- Load raw materials into hoppers or feed systems.

- Monitor material levels and replenish as needed.

3. Quality Control

Monitor and maintain product quality by conducting regular inspections and making necessary adjustments to the extrusion process.

- Inspect extruded products for defects and non-conformances.

- Adjust process parameters to maintain product specifications and minimize rejects.

4. Machine Maintenance

Perform basic maintenance and troubleshooting tasks on extrusion equipment to ensure optimal performance.

- Clean and lubricate machines regularly.

- Identify and resolve minor malfunctions.

Interview Tips

Preparing thoroughly for an Extrusion Process Operator interview is crucial to making a positive impression and showcasing your qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific role you are applying for. This will help you understand their business, culture, and the requirements of the position.

- Visit the company website and social media pages.

- Read industry news and articles to stay up-to-date on trends.

2. Practice Your Answers

Take some time to prepare your answers to common interview questions related to extrusion and manufacturing. Practice speaking clearly and concisely, highlighting your relevant skills and experiences.

- Review common interview questions and prepare your responses.

- Practice answering questions in front of a mirror or with a friend.

3. Show Your Interest

During the interview, demonstrate your interest in the position and the company. Ask thoughtful questions about the role, the industry, and the company’s goals. This shows that you are engaged and eager to learn more.

- Prepare questions to ask the interviewer.

- Show enthusiasm for the role and the company.

4. Highlight Your Skills

Throughout the interview, emphasize your relevant skills and experiences that align with the responsibilities of an Extrusion Process Operator. Quantify your accomplishments and provide specific examples of your work.

- Highlight your experience in extrusion, material handling, quality control, and equipment maintenance.

- Use numbers to demonstrate the impact of your work.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Extrusion Process Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.