Feeling lost in a sea of interview questions? Landed that dream interview for Eyeglass Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Eyeglass Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

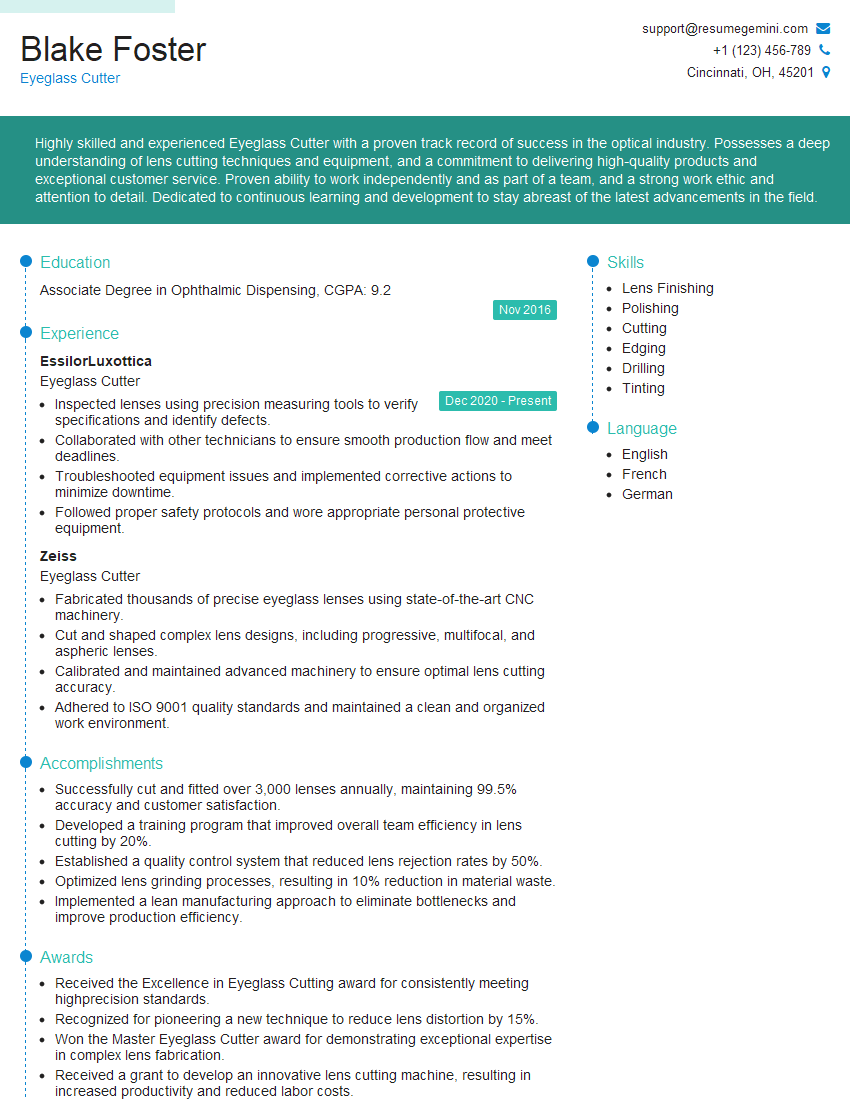

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Eyeglass Cutter

1. Explain the process of cutting and shaping eyeglasses lenses.

The process of cutting and shaping eyeglasses lenses involves several steps:

- Tracing the lens shape: The first step is to trace the desired lens shape onto a blank lens using a template or a lensometer.

- Cutting the lens: The traced shape is then cut out using a diamond-tipped cutting wheel or a laser cutter. The cut must be precise and clean to ensure proper fit and optical clarity.

- Grinding the lens: The cut lens is then ground to refine the shape and create the desired curvature. This is done using a grinding machine with various grits of abrasive wheels.

- Polishing the lens: After grinding, the lens is polished to remove any scratches or imperfections and create a smooth, clear surface. This is done using polishing wheels and compounds.

- Measuring and inspecting the lens: The final step is to measure and inspect the lens to ensure it meets the prescribed specifications for power, shape, and accuracy.

2. What are the different types of eyeglass lenses and their uses?

- Single-vision lenses: These lenses correct for one specific vision problem, such as nearsightedness or farsightedness.

- Multifocal lenses: These lenses correct for multiple vision problems, such as nearsightedness and farsightedness, or presbyopia.

- High-index lenses: These lenses are thinner and lighter than standard lenses, making them ideal for high prescriptions or large frames.

- Photochromic lenses: These lenses darken when exposed to sunlight, providing UV protection and reducing glare.

- Polarized lenses: These lenses block horizontal glare, which can be helpful for driving, fishing, or sports.

3. What are the factors that affect the quality of an eyeglass lens?

- Lens material: The material of the lens, such as glass, plastic, or polycarbonate, can affect its weight, durability, and optical clarity.

- Lens design: The design of the lens, including the shape, curvature, and thickness, can impact its optical performance and comfort.

- Lens coating: Coatings, such as anti-scratch, anti-reflective, and UV protection coatings, can enhance the durability and functionality of the lens.

- Manufacturing process: The quality of the manufacturing process can significantly impact the accuracy, precision, and overall performance of the lens.

4. What safety precautions should be taken when cutting and shaping eyeglasses lenses?

- Wear appropriate safety gear: This includes safety glasses, gloves, and a lab coat or apron.

- Use sharp cutting tools: Dull tools can increase the risk of accidents and poor-quality cuts.

- Handle lenses with care: Lenses can be fragile and should be handled carefully to avoid breakage or damage.

- Dispose of waste properly: Lens cuttings and grinding dust should be disposed of in designated containers to prevent injuries or contamination.

- Follow established safety protocols: Adhere to workplace safety guidelines and regulations to minimize risks.

5. Describe the importance of accurate lens measurements.

Accurate lens measurements are crucial for ensuring the correct vision correction and comfort for the wearer.

- Pupil distance: The distance between the pupils must be measured accurately to ensure that the optical center of the lenses is aligned with the wearer’s eyes.

- Lens power: The power of the lens must be measured precisely to provide the necessary correction for the wearer’s vision.

- Lens size and shape: The size and shape of the lenses must be measured correctly to ensure proper fit and coverage within the frame.

- Lens thickness: The thickness of the lenses can affect the weight and durability of the eyeglasses, so accurate measurements are necessary for optimal performance.

6. Explain how to troubleshoot common problems with eyeglasses lenses.

- Scratches: Scratches on the lenses can be repaired using polishing compounds or replaced if the damage is significant.

- Chips or cracks: Chips or cracks in the lenses require replacement as they can compromise the optical quality and safety of the eyeglasses.

- Poor vision correction: If the eyeglasses are not providing adequate vision correction, the lenses may need to be re-measured or replaced.

- Discomfort or headaches: Discomfort or headaches while wearing eyeglasses can be caused by inaccurate lens measurements or an improper fit, which requires adjustment or replacement.

7. Discuss the role of computer-aided design (CAD) in eyeglass lens manufacturing.

CAD plays a vital role in eyeglass lens manufacturing by:

- Lens design: CAD software allows for the precise design and customization of lens shapes, curvatures, and thicknesses.

- Lens optimization: CAD tools can optimize lens designs to minimize aberrations and maximize optical performance.

- Automation: CAD systems can automate the cutting and shaping processes, ensuring accuracy and consistency.

- Quality control: CAD software can be used to inspect and measure lenses to ensure they meet the desired specifications.

8. What is the importance of staying updated on the latest advances in eyeglass lens technology?

Staying updated on the latest advances in eyeglass lens technology is important for several reasons:

- Improved optical performance: New lens designs and materials can provide better vision correction, reduce glare, and enhance visual comfort.

- Enhanced durability: Advances in lens materials and coatings can improve the scratch resistance, durability, and lifespan of eyeglasses.

- Greater customization: New technologies allow for greater customization of lenses, enabling the creation of eyeglasses that meet specific visual needs and preferences.

- Patient satisfaction: By offering the latest and most advanced lens options, eye care professionals can improve patient satisfaction and overall eyewear experience.

9. How do you ensure quality control during the eyeglass lens manufacturing process?

- Inspection: Lenses are inspected at various stages of the manufacturing process, including cutting, grinding, and polishing, to check for defects or imperfections.

- Measurement: Lenses are measured using specialized equipment to ensure they meet the prescribed specifications for power, shape, and thickness.

- Testing: Lenses are tested for optical clarity, distortion, and other performance parameters to verify their compliance with industry standards.

- Documentation: Quality control records and documentation are maintained to track the manufacturing process and ensure traceability.

10. What are the ethical responsibilities of an eyeglass cutter?

- Patient safety: Ensuring that eyeglasses are manufactured to the highest standards of quality and precision to provide optimal vision correction and safety for the wearer.

- Accuracy and precision: Maintaining meticulous attention to detail and accuracy in all aspects of the lens cutting and shaping process.

- Confidentiality: Respecting the privacy of patients and ensuring that personal information is handled responsibly and securely.

- Continuous improvement: Staying updated on the latest advances in eyeglass lens technology and industry best practices to provide the best possible service to patients.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Eyeglass Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Eyeglass Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Eyeglass Cutter is a highly skilled professional responsible for the precision cutting and shaping of spectacle lenses. Their expertise ensures the accuracy and fit of eyeglasses, meeting the specific requirements of individuals.

1. Lens Cutting and Shaping

Using specialized equipment and techniques, Eyeglass Cutters cut and shape raw lens blanks into the prescribed form and curvature.

- Calculate and mark lens measurements according to the prescription.

- Select and operate cutting machines (e.g., edgers, tracers) to shape and refine lenses.

2. Lens Finishing and Polishing

Eyeglass Cutters finalize the lenses by performing meticulous finishing and polishing processes.

- Smooth and polish lens edges to prevent discomfort and enhance aesthetics.

- Apply coatings and treatments (e.g., anti-scratch, anti-reflective) to improve lens functionality.

3. Quality Control and Inspection

Ensuring the precision and accuracy of eyeglasses is crucial. Eyeglass Cutters conduct thorough inspections.

- Verify lens specifications against prescription requirements.

- Inspect for defects, scratches, or distortions using optical equipment.

4. Customer Service and Communication

Eyeglass Cutters may interact with customers to understand their needs and ensure satisfaction.

- Communicate lens options and recommendations to customers.

- Explain lens features, coatings, and maintenance instructions.

Interview Tips

To ace an interview for an Eyeglass Cutter position, candidates should consider these preparations:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the optical industry. Research current trends, technologies, and regulations.

- Check the company website for mission, values, and recent developments.

- Review industry publications and attend trade shows to stay informed.

2. Practice Your Skills

Showcase your expertise in lens cutting and shaping. Practice using machinery and tools to demonstrate your proficiency.

- Set up a home or lab space to practice lens cutting techniques.

- Seek opportunities to volunteer or assist in an optical workshop.

3. Prepare for Common Interview Questions

Anticipate and prepare responses to questions interviewers might ask. Demonstrate your understanding of the job and highlight your relevant skills and experience.

- Explain your understanding of lens optics, cutting techniques, and quality control.

- Share examples of how you have handled customer inquiries or resolved technical issues.

4. Emphasize Attention to Detail

The precision of eyeglasses requires meticulous attention to detail. Highlight your ability to work with accuracy, focus, and a keen eye for detail.

- In your resume and cover letter, quantify your experience and provide specific examples of how you achieved high precision.

- Emphasize your commitment to quality and ensuring customer satisfaction.

5. Be Professional and Courteous

Make a positive impression with your professionalism and courtesy throughout the interview process.

- Dress appropriately and maintain a positive attitude.

- Listen attentively, ask thoughtful questions, and thank the interviewers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Eyeglass Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.