Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Eyelet Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

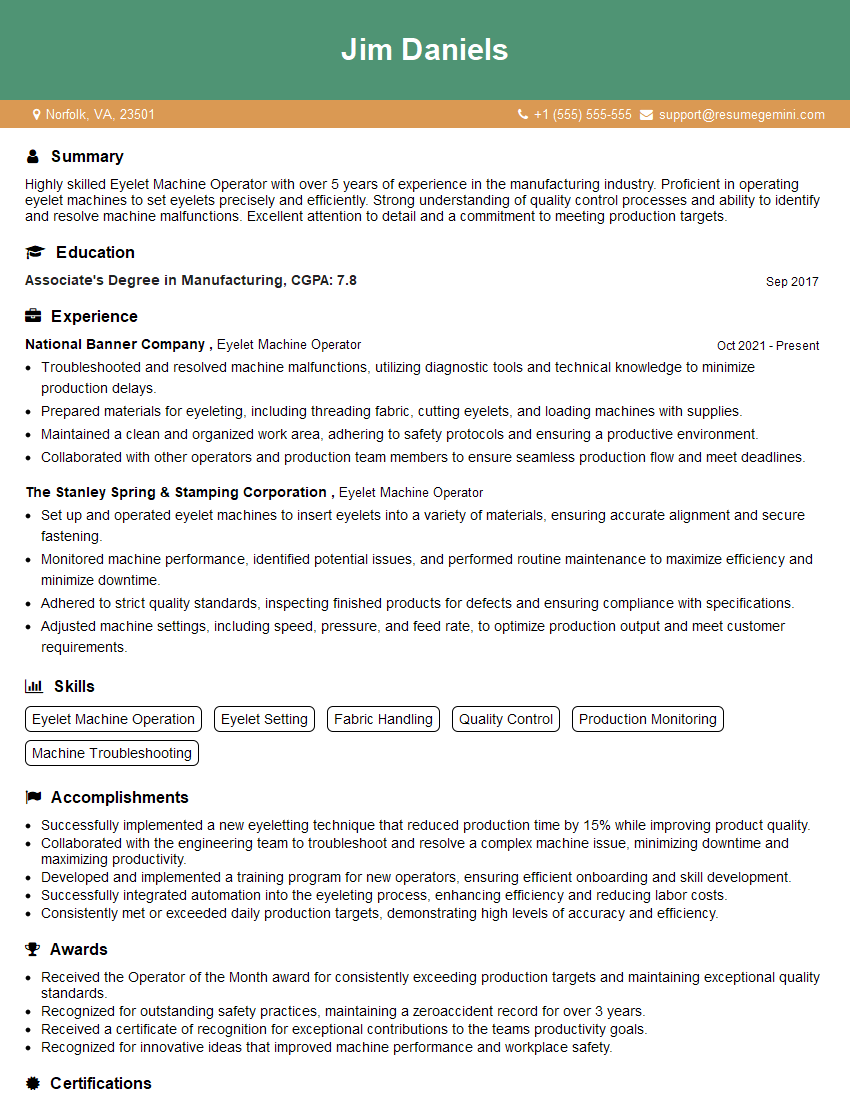

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Eyelet Machine Operator

1. Describe the process of setting up an eyelet machine for a specific type of fabric?

- Inspect the fabric to determine the appropriate eyelet size and spacing.

- Select the correct die and punch for the desired eyelet size.

- Adjust the machine settings, including the speed, pressure, and depth of penetration.

- Load the fabric onto the machine and align it correctly.

- Start the machine and monitor the operation to ensure proper eyelet formation.

2. How do you inspect and maintain an eyelet machine to ensure optimal performance?

Daily Maintenance

- Check oil levels and lubricate moving parts.

- Clean the machine, including the dies, punches, and fabric guides.

- Inspect the electrical components for any damage or loose connections.

Weekly Maintenance

- Thoroughly clean the machine, including all internal components.

- Calibrate the machine settings to ensure precision.

- Inspect the dies and punches for wear and tear, and replace if necessary.

Monthly Maintenance

- Perform a comprehensive inspection of the machine, including all electrical and mechanical components.

- Replace any worn or damaged parts.

- Test the machine to ensure it meets performance specifications.

3. What are the most common problems encountered when operating an eyelet machine, and how do you troubleshoot them?

- Problem: Eyelets are not forming properly.

- Troubleshooting: Check the die and punch for wear or damage, adjust machine settings, or inspect the fabric for any irregularities.

- Problem: Machine is overheating.

- Troubleshooting: Check oil levels, clean the machine to remove any debris, and inspect electrical components for any damage or loose connections.

- Problem: Machine is making excessive noise or vibrations.

- Troubleshooting: Inspect moving parts for wear or damage, lubricate as required, and check the machine’s alignment.

4. How do you determine the correct eyelet size and spacing for a particular application?

- Consider the type and thickness of the fabric.

- Determine the desired strength and durability of the eyelet.

- Consult with the product designer or customer to determine any specific requirements.

- Refer to industry standards or manufacturer’s recommendations.

- Conduct testing to evaluate the performance of different eyelet sizes and spacings.

5. What are the safety precautions that must be taken when operating an eyelet machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands and fingers clear of the machine’s moving parts.

- Never attempt to clean or adjust the machine while it is running.

- Disconnect the machine from power before performing any maintenance or repairs.

- Follow all manufacturer’s instructions and safety guidelines.

6. How do you ensure the quality of eyelets produced by the machine?

- Regularly inspect the dies and punches for wear or damage.

- Maintain consistent machine settings.

- Use high-quality materials.

- Conduct regular quality checks on the finished product.

- Implement a quality management system.

7. What is your experience with different types of eyelet machines?

- Provide a brief overview of the different types of eyelet machines you have worked with.

- Describe your experience with each type of machine, including the specific tasks you performed.

- Explain how your experience has prepared you for this role.

8. How do you stay up-to-date with the latest advancements in eyelet machine technology?

- Attend industry conferences and trade shows.

- Read technical journals and publications.

- Participate in online forums and discussions.

- Connect with other professionals in the field.

- Seek opportunities for training and professional development.

9. How do you handle a situation where the eyelet machine is not performing optimally?

- Calmly assess the situation and identify the problem.

- Refer to the machine’s manual or consult with a supervisor.

- Perform necessary troubleshooting steps.

- If the problem cannot be resolved, contact a qualified technician.

- Keep a record of the problem and the steps taken to resolve it.

10. Why are you interested in this Eyelet Machine Operator position?

- Express your passion for working with machinery and manufacturing processes.

- Highlight your specific skills and experience that align with the requirements of the role.

- Explain how your goals and career aspirations fit with the company’s objectives.

- Convey your enthusiasm for contributing to the team and making a positive impact.

- Demonstrate your commitment to safety and quality workmanship.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Eyelet Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Eyelet Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Eyelet Machine Operators are responsible for operating eyelet machines to insert eyelets into various materials, such as fabric, leather, and paper. Their key responsibilities include:

1. Machine Operation and Maintenance

- Setting up, operating, and monitoring eyelet machines to ensure accurate and efficient insertion of eyelets.

- Performing routine maintenance and troubleshooting on eyelet machines, including cleaning, lubrication, and minor repairs.

2. Material Handling

- Loading and unloading materials from eyelet machines, ensuring proper alignment and positioning.

- Inspecting materials for defects or damage before and after eyelet insertion.

3. Quality Control

- Monitoring the quality of eyelet insertions, ensuring they meet specified standards for strength, uniformity, and appearance.

- Conducting regular inspections and making adjustments to machinery to maintain optimal quality.

4. Production Monitoring

- Maintaining production records and tracking machine performance to identify areas for improvement.

- Communicating production-related issues to supervisors and resolving them promptly.

Interview Tips

To ace an interview for an Eyelet Machine Operator position, candidates should:

1. Research the Company and Role

- Visit the company website and learn about its products, services, and industry.

- Review the job description carefully and identify the specific requirements and responsibilities.

2. Highlight Relevant Skills and Experience

- Emphasize any prior experience in operating eyelet machines or similar equipment.

- Demonstrate strong attention to detail, manual dexterity, and problem-solving abilities.

3. Prepare for Technical Questions

- Be prepared to answer questions about eyelet machine operation, maintenance, and troubleshooting.

- Consider bringing examples of your work or projects that showcase your technical skills.

4. Show Enthusiasm and Motivation

- Express your interest in the role and the company’s industry.

- Highlight your eagerness to learn and contribute to the team.

5. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Practice your answers out loud or with a mock interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Eyelet Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.