Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Eyelet Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

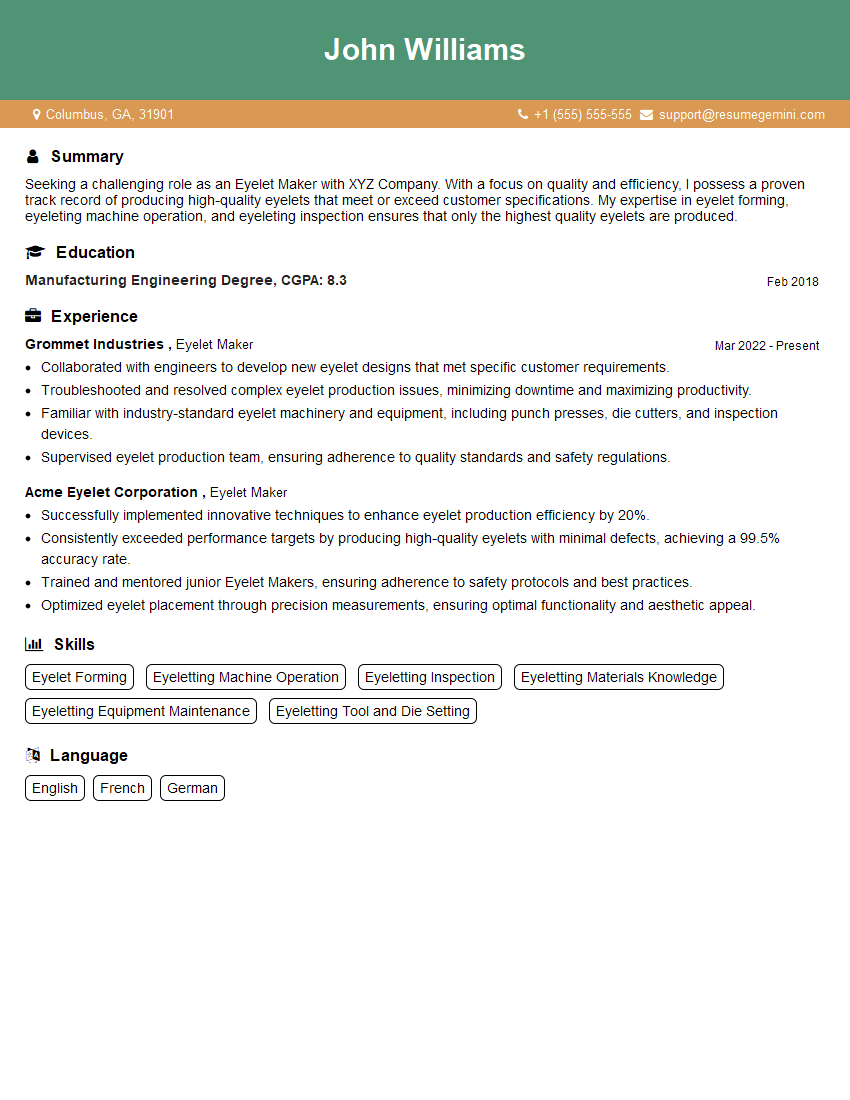

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Eyelet Maker

1. What types of eyelet machines are you familiar with?

As an Eyelet Maker, I am well-versed in operating various types of eyelet machines, including:

- Manual Eyelet Machines: Hand-operated machines used for small-scale production, ideal for precise placement.

- Semi-Automatic Eyelet Machines: Machines that assist in feeding and setting eyelets, increasing efficiency.

- Automatic Eyelet Machines: High-speed machines that automate the entire eyeleting process, ensuring consistent results.

- CNC Eyelet Machines: Computer-controlled machines that offer precision, speed, and flexibility in eyeleting various materials.

2. What factors should be considered when selecting the right eyelet size for a project?

Material Thickness

- The thickness of the material determines the size of the eyelet required to provide adequate strength and prevent tearing.

Eyelet Strength

- The intended use and load-bearing requirements influence the strength of the eyelet needed.

Material Type

- Different materials, such as fabric, leather, or plastic, may require specific eyelet types and sizes to ensure proper adhesion.

Eyelet Finish

- The desired finish, such as nickel-plated or brass, may also impact the choice of eyelet size.

3. How do you ensure the quality and accuracy of eyeleting?

To ensure quality and accuracy, I follow these practices:

- Proper Machine Setup: Calibrating and adjusting machines to the correct settings for the specific eyelets and materials.

- Material Inspection: Checking materials for defects or irregularities that could affect eyelet placement.

- Eyelet Selection: Choosing the appropriate eyelet size and type based on material thickness and requirements.

- Accurate Placement: Using templates or guides to ensure precise eyelet placement and spacing.

- Visual Inspection: Regularly inspecting finished products to identify and correct any defects.

4. Describe the process of installing eyelets using a manual eyelet machine.

- Punch a Hole: Create a hole in the material using a punch tool.

- Insert Eyelet: Place the eyelet through the hole from the back.

- Set Eyelet: Use the anvil and punch to press the eyelet firmly in place.

- Form Head: Apply pressure to the eyelet head to form a raised head.

- Inspect: Check the eyelet for secure installation and proper finish.

5. What troubleshooting techniques do you use when encountering problems with eyelet machines?

- Blocked or Misaligned Dies: Check and clean dies for debris or misalignment, ensuring they are properly seated.

- Incorrect Eyelet Size: Verify that the eyelet size matches the hole size and material thickness.

- Damaged Punch: Inspect the punch for damage or dullness, and replace if necessary.

- Improper Machine Settings: Calibrate and adjust machine settings, such as pressure and speed, to optimal levels.

- Material Defects: Examine the material for tears or irregularities that may hinder eyelet placement.

6. Explain how you maintain and care for eyelet machines to ensure their longevity.

To maintain eyelet machines and prolong their lifespan, I adhere to the following practices:

- Regular Cleaning: Cleaning machines regularly to remove dust, debris, and lubrication residue.

- Lubrication: Applying lubricants to moving parts to reduce friction and ensure smooth operation.

- Die Maintenance: Sharpening or replacing dies when they become dull to maintain precision and prevent damage.

- Electrical Inspections: Checking electrical connections and components to identify and address any issues promptly.

- Proper Storage: Storing machines in a clean and dry environment when not in use.

7. Describe the different types of materials that can be eyeletted and their specific requirements.

- Fabrics: Different fabrics require specific eyelet types and sizes based on thickness and weave.

- Leather: Eyeleting leather requires durable eyelets and careful hole punching to prevent tearing.

- Plastic: Eyelets must be heat-resistant and compatible with the type of plastic being used.

- Rubber: Eyelets for rubber need to be strong and flexible to withstand stretching and movement.

- Metal: Eyeleting metal requires specialized techniques and machines to create strong and secure fastenings.

8. What safety precautions should be taken when working with eyelet machines?

- Wear Protective Gear: Using safety glasses and gloves to protect from flying debris or sharp edges.

- Machine Guarding: Ensuring proper guarding around moving parts to prevent contact.

- Electrical Safety: Following electrical safety procedures and using grounded equipment.

- Proper Lighting: Maintaining adequate lighting to enhance visibility and prevent accidents.

- Training and Supervision: Receiving proper training and supervision to operate machines safely.

9. How do you stay updated on the latest techniques and advancements in eyeleting technology?

- Industry Publications: Reading trade magazines and journals to stay informed about new products and techniques.

- Conferences and Exhibitions: Attending industry events to learn from experts and explore emerging technologies.

- Online Resources: Utilizing online forums, articles, and videos to access up-to-date information.

- Manufacturer Support: Consulting with equipment manufacturers for technical support and information on advancements.

10. What is your approach to working with clients to understand their eyeleting needs and deliver satisfactory results?

To work effectively with clients, I follow a collaborative approach:

- Active Listening: Listening attentively to client requirements and understanding their specific needs.

- Consultation: Providing expert advice on eyelet types, sizes, and materials to achieve optimal results.

- Sample Provision: Offering samples to demonstrate different eyeleting options and finalize the desired outcome.

- Quality Assurance: Ensuring high-quality eyeleting that meets or exceeds client expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Eyelet Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Eyelet Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Eyelets are small, metal or plastic rings that are inserted into fabric or other materials to create holes for lacing or other purposes. Eyelet Makers are responsible for producing these eyelets in a variety of sizes and styles. Their key job responsibilities include:

1. Setting up and operating eyelet making machines

Eyelet Makers must be able to set up and operate eyelet making machines in order to produce eyelets of the desired size and shape. This involves calibrating the machine, loading the raw materials, and ensuring that the machine is running smoothly.

- Calibrating the eyelet making machine to ensure that it is producing eyelets of the correct size and shape.

- Loading the raw materials, such as metal or plastic, into the machine.

- Monitoring the machine during operation to ensure that it is running smoothly and that the eyelets are being produced correctly.

2. Inspecting eyelets for quality

Eyelet Makers must be able to inspect eyelets for quality to ensure that they meet the customer’s specifications. This involves checking the eyelets for defects, such as cracks, burrs, or other imperfections.

- Visually inspecting eyelets for defects, such as cracks, burrs, or other imperfections.

- Using gauges or other tools to measure the size and shape of eyelets.

- Rejecting eyelets that do not meet the customer’s specifications.

3. Packaging and shipping eyelets

Eyelet Makers must be able to package and ship eyelets to customers in a timely and efficient manner. This involves packaging the eyelets in boxes or other containers, and then shipping the containers to the customer’s desired location.

- Packaging eyelets in boxes or other containers.

- Shipping the containers to the customer’s desired location.

- Ensuring that the eyelets are packaged and shipped in a way that protects them from damage.

4. Maintaining a clean and organized work area

Eyelet Makers must be able to maintain a clean and organized work area in order to ensure that the eyelets are produced in a safe and efficient manner. This involves cleaning the machines, sweeping the floor, and disposing of waste materials.

- Cleaning the eyelet making machines on a regular basis.

- Sweeping the floor around the eyelet making machines.

- Disposing of waste materials, such as metal shavings or plastic scraps.

Interview Tips

In order to ace the interview for an Eyelet Maker position, it is important to be well-prepared. Here are a few tips to help you prepare:

1. Research the company and the position

Before the interview, take some time to research the company and the Eyelet Maker position. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on the company’s website, Glassdoor, and other online resources.

- Visit the company’s website to learn more about the company’s history, products, and services.

- Read reviews of the company on Glassdoor and other online resources to get a sense of the company’s culture and values.

- Review the job description carefully to understand the specific requirements of the Eyelet Maker position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions and practice saying them aloud.

- Ask a friend or family member to mock interview you so that you can get feedback on your answers.

- Time yourself to make sure that your answers are concise and within the allotted time.

3. Dress professionally and arrive on time for the interview

First impressions matter, so it is important to dress professionally and arrive on time for the interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive for the interview on time, or even a few minutes early.

- Be polite and respectful to the interviewer and other staff members.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Be sure to convey your interest in the position and in the company during the interview. Talk about your skills and experience, and how they would benefit the company.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Eyelet Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.