Feeling lost in a sea of interview questions? Landed that dream interview for Fabric Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fabric Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

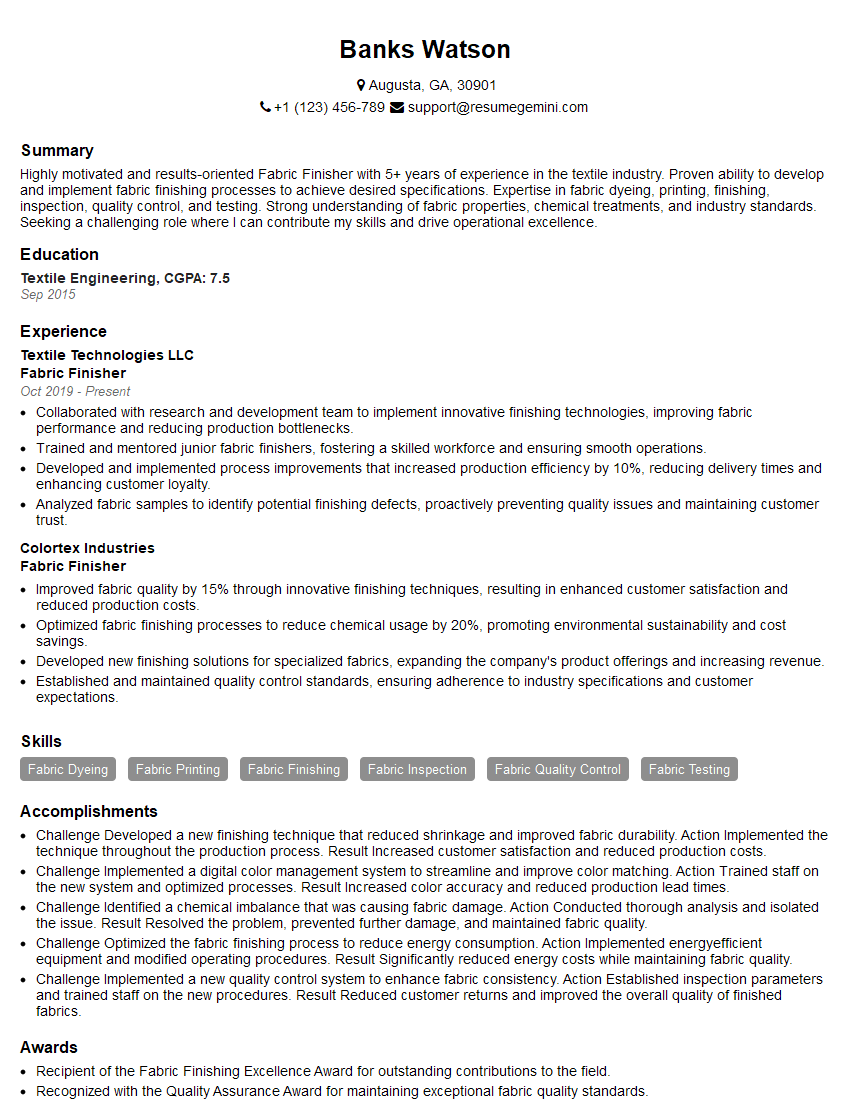

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabric Finisher

1. What are the different types of fabric finishes and their applications?

There are numerous types of fabric finishes, each with its own unique properties and applications. Some of the most common types include:

- Wrinkle-resistant finishes: These finishes make fabrics less prone to wrinkling and creasing, making them ideal for garments and other textiles that require a polished appearance.

- Water-repellent finishes: These finishes make fabrics resistant to water and moisture, making them suitable for outdoor fabrics, rainwear, and other items that need to withstand wet conditions.

- Flame-retardant finishes: These finishes make fabrics less flammable, reducing the risk of fire and burns. They are often used in curtains, upholstery, and other textiles in public spaces.

- Antimicrobial finishes: These finishes inhibit the growth of bacteria and other microorganisms, making them ideal for use in healthcare settings, food preparation areas, and other environments where hygiene is important.

- Soil-release finishes: These finishes help to prevent dirt and stains from adhering to fabrics, making them easier to clean and maintain.

2. What are the key factors to consider when selecting a fabric finish?

Factors to Consider

- The intended use of the fabric: The type of finish you choose will depend on the specific application the fabric will be used for. For example, a water-repellent finish would be ideal for a raincoat, while a wrinkle-resistant finish would be more suitable for a business suit.

- The fiber content of the fabric: Different fibers require different types of finishes. For example, synthetic fibers may require different finishes than natural fibers.

- The desired appearance of the fabric: Some finishes can alter the appearance of the fabric, such as by adding a sheen or changing the color. It is important to consider the desired appearance when selecting a finish.

- The cost of the finish: Different finishes can vary in cost. It is important to factor in the cost when making your decision.

3. What are the different methods of applying fabric finishes?

There are various methods of applying fabric finishes, including:

- Padding: This method involves applying the finish to the fabric using a pad or roller.

- Dipping: This method involves immersing the fabric in a bath of the finish.

- Spraying: This method involves spraying the finish onto the fabric.

- Brushing: This method involves brushing the finish onto the fabric.

- Curing: After the finish has been applied, it is typically cured to ensure it bonds properly to the fabric.

4. What are the common defects that can occur during fabric finishing?

Various defects can occur during fabric finishing, such as:

- Wrinkles and creases: These can be caused by improper handling or storage of the fabric.

- Color variation: This can be caused by uneven application of the finish or by using the wrong type of finish for the fabric.

- Staining: This can be caused by improper handling or storage of the fabric, or by using the wrong type of finish for the fabric.

- Shrinkage: This can be caused by using the wrong type of finish for the fabric or by using too much heat during the curing process.

- Loss of strength: This can be caused by using the wrong type of finish for the fabric or by using too much heat during the curing process.

5. How do you ensure the quality of finished fabrics?

To ensure the quality of finished fabrics, it is important to:

- Use high-quality materials: The quality of the finished fabric will depend on the quality of the materials used.

- Follow the manufacturer’s instructions: It is important to follow the manufacturer’s instructions for applying and curing the finish.

- Inspect the finished fabric: After the fabric has been finished, it should be inspected for any defects.

6. What are the latest trends in fabric finishing?

The latest trends in fabric finishing include:

- Sustainable finishes: There is a growing demand for sustainable finishes that are environmentally friendly and reduce the use of harmful chemicals.

- Performance finishes: Performance finishes are designed to improve the performance of fabrics, such as by making them more wrinkle-resistant, water-repellent, or antimicrobial.

- Digital printing: Digital printing is a new technology that allows for the creation of complex and detailed patterns on fabrics.

7. What are the challenges in fabric finishing?

Some of the challenges in fabric finishing include:

- Achieving the desired finish: It can be challenging to achieve the desired finish, especially when using new or complex finishes.

- Maintaining the quality of the fabric: It is important to ensure that the finishing process does not damage or degrade the fabric.

- Meeting environmental regulations: Fabric finishing can involve the use of harmful chemicals, so it is important to meet environmental regulations.

8. What are your strengths and weaknesses as a fabric finisher?

Strengths:

- I have a strong understanding of the different types of fabric finishes and their applications.

- I have experience in applying a variety of fabric finishes using different methods.

- I am able to troubleshoot and resolve problems that may occur during the fabric finishing process.

Weaknesses:

- I am still learning about the latest trends in fabric finishing.

- I have limited experience in working with some of the newer, more complex fabric finishes.

9. What are your career goals as a fabric finisher?

My career goals are to:

- Become an expert in fabric finishing.

- Develop new and innovative fabric finishes.

- Start my own fabric finishing business.

10. Do you have any questions for me?

I am interested in learning more about the company’s commitment to sustainability. Can you tell me more about the company’s environmental policies?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabric Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabric Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabric Finishers are responsible for treating and finishing fabrics to enhance their quality, appearance, and performance. Their primary duties include:

1. Fabric Treatment

Applying specific chemical treatments, such as dyeing, bleaching, and softening, to alter the color, texture, and hand of the fabric.

- Selecting and mixing appropriate chemicals and dyes based on fabric type and desired outcome

- Operating dyeing and finishing machines to apply treatments accurately and consistently

2. Fabric Finishing

Using specialized techniques and equipment to finish fabrics, including brushing, shearing, calendering, and pressing, to achieve the desired appearance and drape.

- Adjusting machine settings to control fabric tension, temperature, and pressure

- Inspecting finished fabrics for defects and ensuring they meet quality standards

3. Quality Control

Monitoring and maintaining the quality of fabrics throughout the finishing process, including testing for colorfastness, shrinkage, and other performance characteristics.

- Performing regular quality checks and reporting any discrepancies

- Collaborating with production team to improve processes and minimize defects

4. Equipment Maintenance

Maintaining and calibrating dyeing and finishing machines, including cleaning, lubricating, and performing minor repairs.

- Identifying potential equipment malfunctions and scheduling maintenance as needed

- Ensuring machines are operating efficiently and safely

Interview Tips

To ace your interview for a Fabric Finisher position, consider the following tips:

1. Research the Company and Role

Demonstrate your interest and knowledge by thoroughly researching the textile industry, the company’s products, and the specific responsibilities of the Fabric Finisher role.

- Visit the company’s website, read industry publications, and connect with current or former employees on LinkedIn

- Prepare specific questions about the company’s fabric finishing processes and any sustainability initiatives

2. Highlight Your Technical Skills

Emphasize your proficiency in fabric treatment and finishing techniques, such as dyeing, bleaching, and calendering. Discuss your experience with different types of fabrics and chemicals.

- Quantify your accomplishments with specific examples of how you improved fabric quality or efficiency

- Demonstrate your knowledge of industry standards and best practices for fabric finishing

3. Showcase Your Problem-Solving Abilities

Describe situations where you encountered challenges in fabric finishing and how you solved them. Highlight your analytical skills, attention to detail, and ability to work independently and as part of a team.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Provide specific examples of how you identified root causes of problems and implemented effective solutions

4. Emphasize Your Commitment to Quality

Stress your commitment to delivering high-quality finished fabrics. Discuss your understanding of quality control procedures and your ability to inspect and evaluate fabrics.

- Explain how you ensure that fabrics meet specifications and customer expectations

- Highlight your experience with quality improvement initiatives or certification programs

5. Ask Thoughtful Questions

Ask insightful questions that demonstrate your interest and engagement during the interview. This not only shows your enthusiasm but also allows you to clarify any uncertainties or gather additional information.

- Inquire about the company’s plans for innovation in fabric finishing

- Ask about opportunities for professional development and growth within the organization

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fabric Finisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fabric Finisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.