Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fabric Lay Out Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fabric Lay Out Worker so you can tailor your answers to impress potential employers.

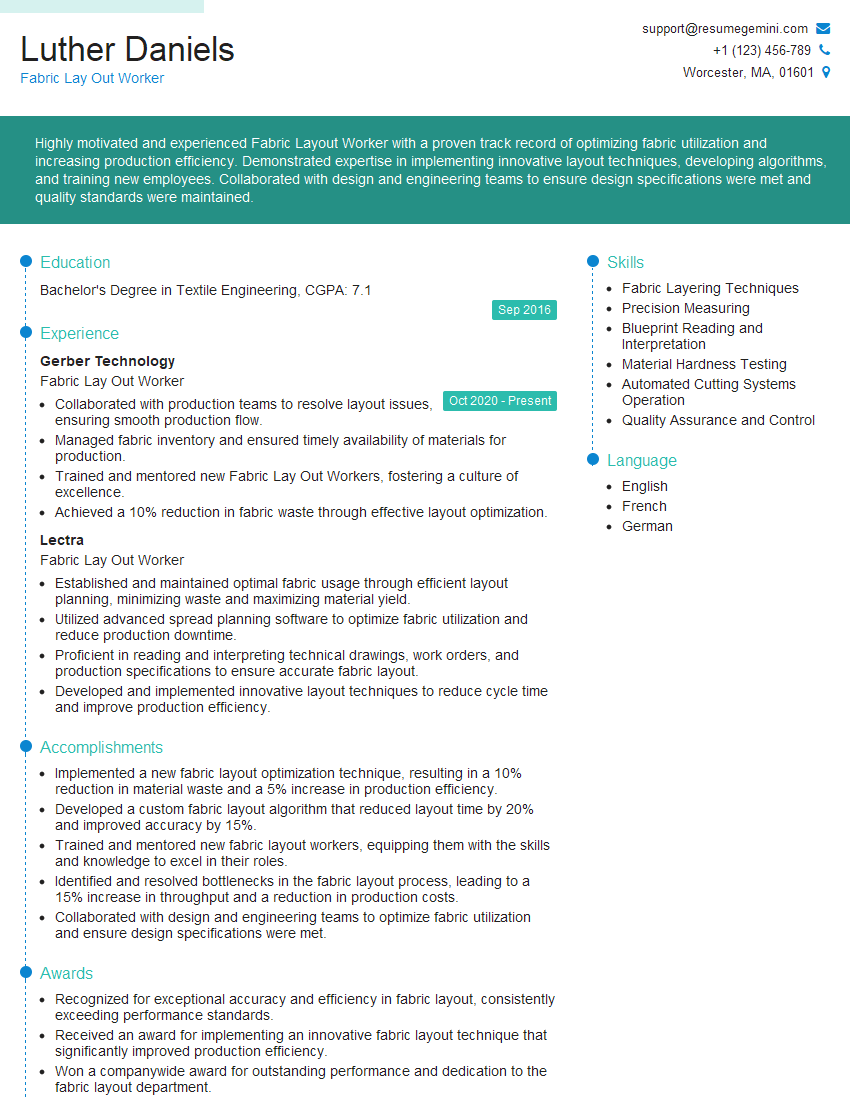

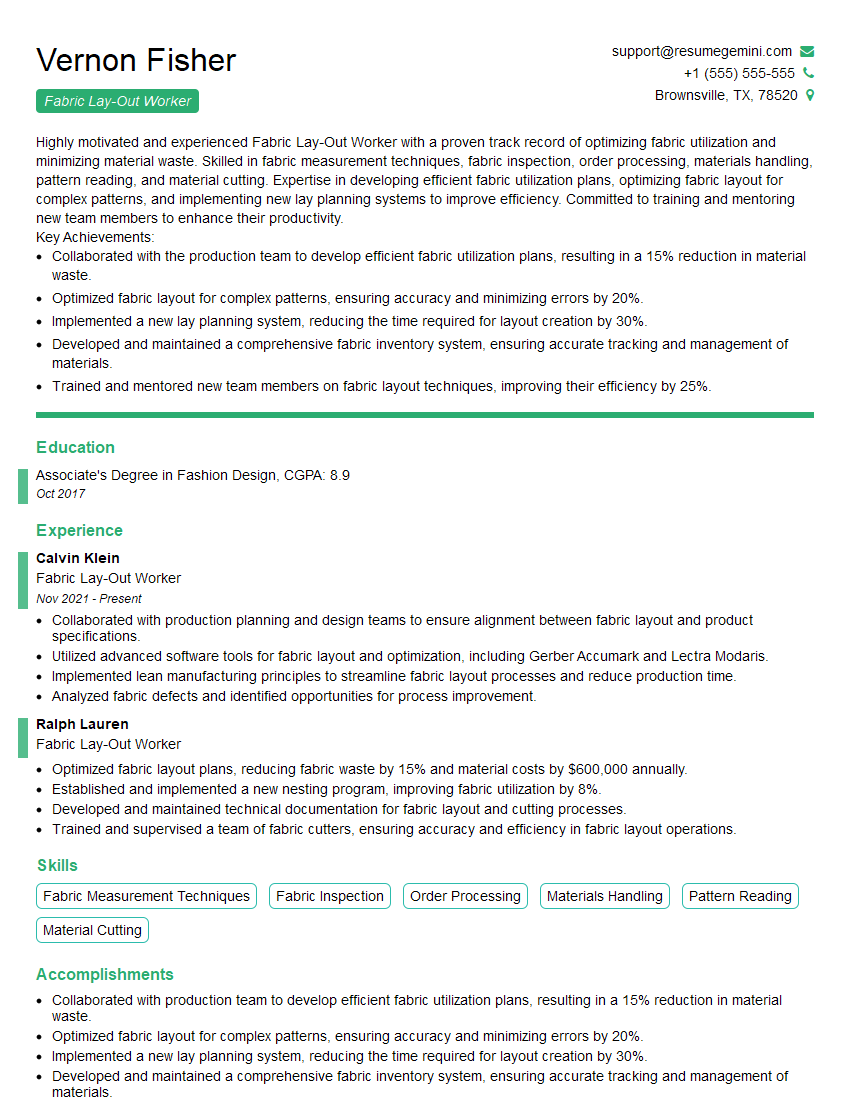

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabric Lay Out Worker

1. Describe the key responsibilities of a Fabric Lay Out Worker?

The primary responsibilities of a Fabric Lay Out Worker include:

- Preparing fabric for cutting by measuring, marking, and spreading it accurately.

- Checking fabric for defects, tears, or stains to ensure quality.

- Using cutting machines or hand tools to cut fabric according to specified patterns.

- Bundling and labeling cut fabric for further processing.

- Maintaining a clean and organized work area to ensure efficiency and safety.

2. Explain the importance of proper fabric measurement and marking in the lay out process?

Precise measurement and marking are crucial in the lay out process for several reasons:

- Accurate cutting: Ensures that fabric is cut to the exact dimensions required for the garment or product.

- Efficient cutting: Minimizes waste by maximizing the utilization of fabric and preventing incorrect cuts.

- Quality control: Proper marking allows for easy identification of fabric defects or errors, enabling timely rectification.

- Consistency: Ensures uniformity and conformity in the finished garments or products.

3. What are the different techniques used for spreading fabric?

Fabric spreading techniques vary depending on the type of fabric and the desired result:

- Manual spreading: Involves manually laying out the fabric on a table or floor without the use of machines.

- Machine spreading: Utilizes spreading machines that automatically unroll and position the fabric on a table.

- Bias spreading: Fabrics are spread at an angle to the grain line, creating a diagonal orientation.

- Layering: Multiple layers of fabric are spread on top of each other for specific patterns or designs.

4. How do you ensure fabric alignment during laying out?

To ensure proper fabric alignment during lay out, several methods can be employed:

- Grid system: Using a marked grid on the table or floor to guide fabric placement.

- Reference points: Identifying and marking specific reference points on the fabric for alignment.

- Measuring tools: Utilizing rulers or measuring tapes to ensure precise measurements and alignment.

- Optical alignment devices: Employing lasers or projectors to project alignment guides onto the fabric.

5. What are the common types of cutting machines used in fabric lay out?

Various types of cutting machines are used in fabric lay out to achieve different cutting precision and efficiency:

- Band knife cutting machines: Use a continuous rotating band knife to cut through multiple layers of fabric.

- Straight knife cutting machines: Utilize a reciprocating straight knife to cut through fabric.

- Die cutting machines: Employ sharp dies to cut specific shapes or designs into the fabric.

- Laser cutting machines: Utilize a laser beam to precisely cut intricate patterns or perforations into the fabric.

6. Describe the importance of safety precautions in the fabric lay out process?

Safety is paramount in fabric lay out due to potential hazards:

- Sharp tools: Knives and cutting machines pose a risk of cuts and lacerations.

- Heavy fabric: Lifting and moving rolls of fabric can cause strains or injuries.

- Electrical equipment: Cutting machines and other equipment require proper handling to avoid shocks.

- Noise: Cutting machines can generate noise levels that may damage hearing.

Implementing safety measures like wearing protective gear, using sharp tools correctly, and maintaining a clean work area is crucial.

7. How do you maintain the quality of fabric during the lay out process?

Maintaining fabric quality involves several key practices:

- Defect inspection: Checking fabric for defects or imperfections before cutting.

- Proper handling: Avoiding dragging or folding fabric to prevent damage.

- Clean equipment: Keeping cutting machines and tools clean to prevent fabric contamination.

- Storage conditions: Storing fabric in a controlled environment to prevent fading, shrinkage, or mildew.

8. Explain how you minimize fabric waste in the lay out process?

Minimizing fabric waste requires careful planning and efficient techniques:

- Optimized spreading: Arranging fabric patterns to maximize fabric utilization and reduce waste.

- Marker efficiency: Using software or manual techniques to create cutting patterns that minimize fabric remnants.

- Reusing fabric scraps: Identifying ways to incorporate smaller pieces of fabric into other designs or products.

- Recycling: Implementing recycling programs for fabric waste to reduce environmental impact.

9. Describe the importance of communication and teamwork in the fabric lay out process?

Effective communication and teamwork are crucial for efficient fabric lay out operations:

- Communication with designers: Understanding design specifications and requirements.

- Coordination with cutters: Ensuring proper fabric preparation and cutting accuracy.

- Collaboration with production team: Providing updates on fabric availability and progress.

- Problem-solving: Addressing issues or challenges as a team to find solutions.

10. What are the key performance indicators (KPIs) you track to measure your productivity and efficiency as a Fabric Lay Out Worker?

Key performance indicators (KPIs) for measuring productivity and efficiency in fabric lay out include:

- Fabric utilization rate: Percentage of fabric utilized in cutting compared to total fabric received.

- Lay out speed: Time taken to prepare and lay out fabric for cutting.

- Accuracy: Number of defects or errors in fabric preparation and cutting.

- Waste reduction: Percentage of fabric waste generated during lay out.

- Safety compliance: Adherence to safety protocols and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabric Lay Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabric Lay Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabric Lay Out Workers plays an important role in textile industry. They are responsible for accurately laying out fabric pieces on a table and aligning them with templates to create patterns for cutting and sewing garments

1. Laying Out Fabric

Fabric Lay Out Workers need to have strong attention to detail and precision to ensure that each piece is placed in the correct position and aligned perfectly.

- Prepare the fabric by inspecting it for defects and measuring it accurately.

- Decide how the fabric should be folded or draped in order to utilize the maximum area.

- Align the fabric with templates and patterns using measuring tools.

2. Cutting Fabric

Once the fabric has been laid out, Fabric Lay Out Workers may be responsible for cutting it into the desired shapes.

- Use cutting tools such as shears or knives to cut the fabric along the marked lines.

- Ensure that the cut pieces are accurate and free of any defects.

3. Maintaining a Clean and Safe Work Environment

Fabric Lay Out Workers need to maintain a clean and safe work environment to prevent accidents and ensure the quality of the fabric.

- Keep the work area clean and free of debris.

- Follow all safety procedures and use proper equipment.

- Dispose of waste materials properly.

4. Inspecting Fabric for Defects

Fabric Lay Out Workers may also be responsible for inspecting fabric for defects.

- Inspect the fabric for any tears, holes, or stains.

- Identify and mark any defects so that they can be repaired or discarded.

Interview Tips

To ace your interview, it’s important to be prepared. By following some quick tips, you can make a great impression on the interviewer.

1. Research the Company and Position

Before you go to the interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate. It will also help you answer questions about your qualifications and why you are interested in the position.

- Visit the company’s website.

- Find their social media pages.

- What are their goals and values?

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. Take the time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Research interview questions.

- Practice your answers with a friend or family member.

3. Dress Professionally

First impressions matter, so it’s important to dress appropriately for your interview.

- Choose clothes that are clean, pressed, and fit you well.

- Choose appropriate shoes, jewelry, and accessories.

4. Be On Time

Being on time for your interview is a sign of respect for the interviewer’s time.

- Plan your route ahead of time.

- Allow yourself extra time for traffic or delays.

5. Be Professional and Enthusiastic

Throughout the interview, it’s important to be professional and enthusiastic. This means making eye contact, speaking clearly, and being engaged in the conversation. It also means being positive and upbeat about your qualifications and your interest in the position.

- Make eye contact with the interviewer.

- Be positive and enthusiastic.

- Speak clearly and concisely.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabric Lay Out Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!