Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fabric Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fabric Worker so you can tailor your answers to impress potential employers.

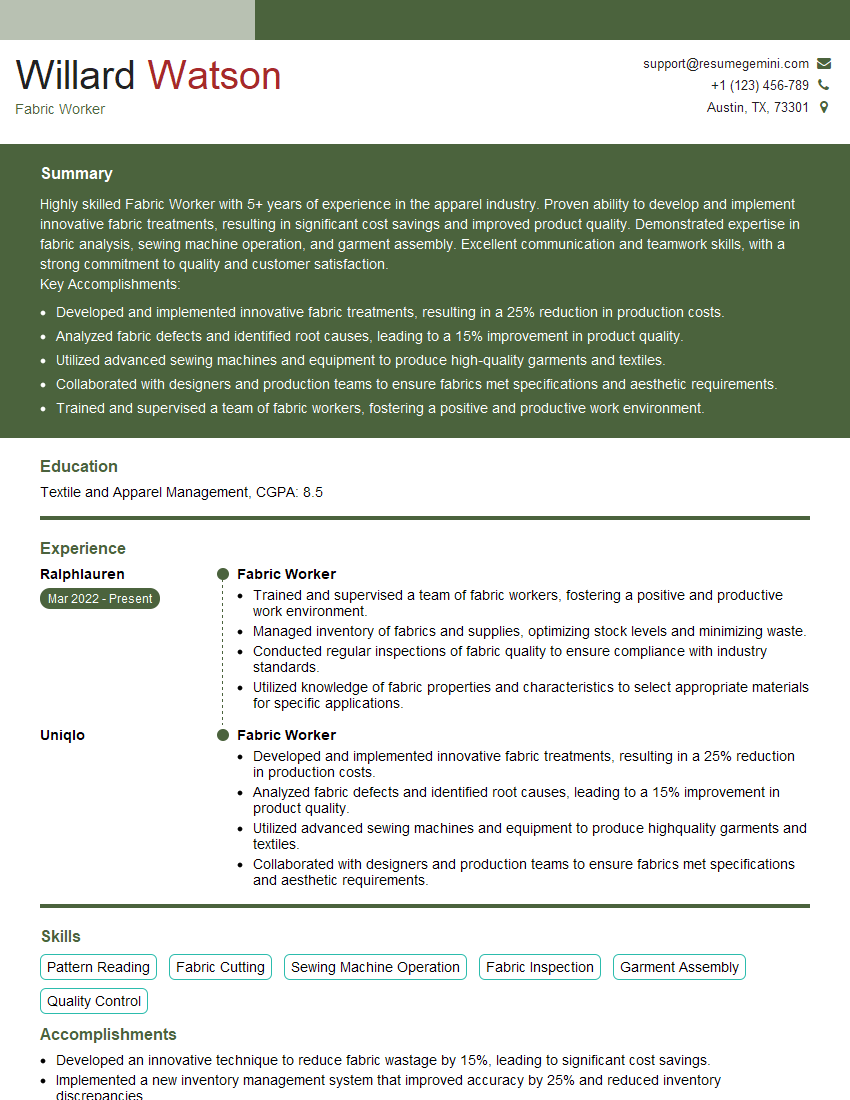

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabric Worker

1. Describe the process of fabric cutting?

- Inspect and prepare the fabric, ensuring it is free of defects and lays flat.

- Determine the grain line and mark it on the fabric.

- Select the appropriate cutting tool (scissors, rotary cutter, or knife) based on the fabric type and thickness.

- Lay out the fabric according to the cutting plan and secure it with weights or pins.

- Cut the fabric along the marked lines, following the grain direction for accuracy and to prevent distortion.

- Inspect the cut pieces for precision and ensure they meet the specified dimensions.

2. What are the different types of sewing machines and their uses in fabric production?

Industrial Sewing Machines

- Lockstitch machines: Used for durable seams on a wide range of fabrics.

- Overlock machines: Trim edges and prevent fraying, creating a clean finish.

- Coverstitch machines: Create stretchy, decorative seams, often used for sportswear and activewear.

Domestic Sewing Machines

- Straight stitch machines: Basic machines suitable for simple sewing projects.

- Sergers: Similar to overlock machines but smaller and designed for home use.

- Embroidery machines: Create intricate designs and embellishments on fabric.

3. Explain the importance of thread selection in fabric sewing?

- Strength: Different thread types have varying tensile strengths, affecting the durability of the seam.

- Elasticity: Threads with higher elasticity can accommodate fabric stretch, preventing seam breakage.

- Material compatibility: Threads should be compatible with the fabric type and its intended use.

- Color: Thread color should match or complement the fabric, depending on the desired aesthetic.

- Texture: Threads come in different textures (e.g., matte, glossy), influencing the appearance of the seam.

4. How do you inspect fabric for defects before cutting and sewing?

- Inspect the fabric visually for holes, tears, stains, or uneven weave.

- Use a light table to illuminate the fabric and reveal any flaws.

- Check the fabric’s hand (feel) to identify any irregularities in texture, weight, or drape.

- Inspect the fabric’s grain to ensure it is straight and even, preventing distortions when cutting.

- Test the fabric’s colorfastness by exposing it to sunlight or washing a small sample to prevent color bleeding or fading.

5. Describe the process of pattern matching when sewing fabrics with patterns?

- Lay out the fabric according to the pattern layout and identify the areas where pattern matching is required.

- Pin the matching points together along the seam line, ensuring the patterns align precisely.

- Stitch along the seam line, taking care to maintain pattern alignment throughout.

- Press the seam open to set the fabric and enhance the pattern match.

- Inspect the seam for accuracy and ensure the pattern is continuous and seamless.

6. What are the common problems encountered in fabric sewing and how do you troubleshoot them?

- Puckering: Caused by uneven tension between the fabric layers; adjust thread tension or use a walking foot.

- Uneven stitching: Caused by a dull needle or incorrect needle size; replace the needle and adjust settings.

- Skipped stitches: Caused by poor thread quality or tension issues; re-thread the machine and check tension.

- Fabric fraying: Caused by inappropriate thread selection or lack of seam finishing; use a compatible thread and consider using a serger or zigzag stitch.

- Fabric distortion: Caused by incorrect cutting or pressing techniques; cut along the grain and press gently using the correct heat setting.

7. What safety precautions should be taken when working with fabric and sewing equipment?

- Wear appropriate clothing, including eye protection and gloves.

- Keep the work area clean and free of tripping hazards.

- Inspect sewing machines and equipment regularly and report any issues promptly.

- Use sharp needles and replace them frequently to prevent breakage and injuries.

- Handle fabrics with caution, avoiding contact with heat sources or sharp objects.

8. Explain the different types of fabric finishes and their applications?

- Anti-wrinkle: Prevents fabric from creasing and wrinkling, often used in formal wear.

- Flame retardant: Protects fabric from catching fire, used in curtains and upholstery.

- Water-repellent: Makes fabric resistant to water and stains, ideal for outdoor or rainwear.

- Shrink-resistant: Prevents fabric from shrinking after washing, ensuring size retention.

- Odor-resistant: Controls unpleasant odors, used in activewear and sportswear.

9. What are the latest trends and innovations in the fabric industry?

- Sustainable fabrics: Eco-friendly and biodegradable materials, reducing environmental impact.

- Smart textiles: Incorporate technology, such as sensors or heat regulation, for enhanced functionality.

- 3D printing: Creates custom fabrics with intricate designs and complex structures.

- Advanced finishing techniques: Develop innovative finishes to enhance fabric properties and aesthetics.

- Digital printing: Enables high-quality, colorful prints on fabrics, expanding design possibilities.

10. How do you stay updated with the latest developments and best practices in fabric working?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Connect with other professionals on social media and industry forums.

- Seek opportunities for professional development and training.

- Experiment with new fabrics and techniques to expand knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabric Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabric Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabric Workers are responsible for a wide range of duties related to the production and maintenance of fabrics and textiles.

1. Fabric Production

Fabric Workers operate machines to weave, knit, or otherwise produce fabrics.

- Set up and operate machines according to specifications.

- Monitor processes and make adjustments as needed.

2. Fabric Inspection

Fabric Workers inspect fabrics for defects and ensure that they meet quality standards.

- Examine fabrics visually and with instruments.

- Identify and mark defects.

3. Fabric Maintenance

Fabric Workers Perform maintenance on machines and equipment used in fabric production.

- Clean and lubricate machines.

- Make minor repairs.

4. Other Duties

Fabric Workers may also perform other duties related to fabric production, such as:

- Packing and shipping fabrics.

- Maintaining records of fabric production.

Interview Tips

Preparing thoroughly for a Fabric Worker interview can significantly increase your chances of success. Here are some essential tips:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific Fabric Worker position.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles to stay up-to-date on the latest trends in fabric production.

2. Practice Your Answers

Anticipate common interview questions and practice your answers. This will help you feel more confident and articulate during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your skills and experience that are relevant to the position.

3. Be Prepared to Talk About Safety

Safety is paramount in the textile industry. Be prepared to discuss your experience with safety protocols and regulations.

- Explain how you ensure safety in your work environment.

- Describe any safety training or certifications you have.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are interested and engaged.

- Ask about the company’s culture and values.

- Inquire about opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fabric Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.