Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fabrication and Assembly Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

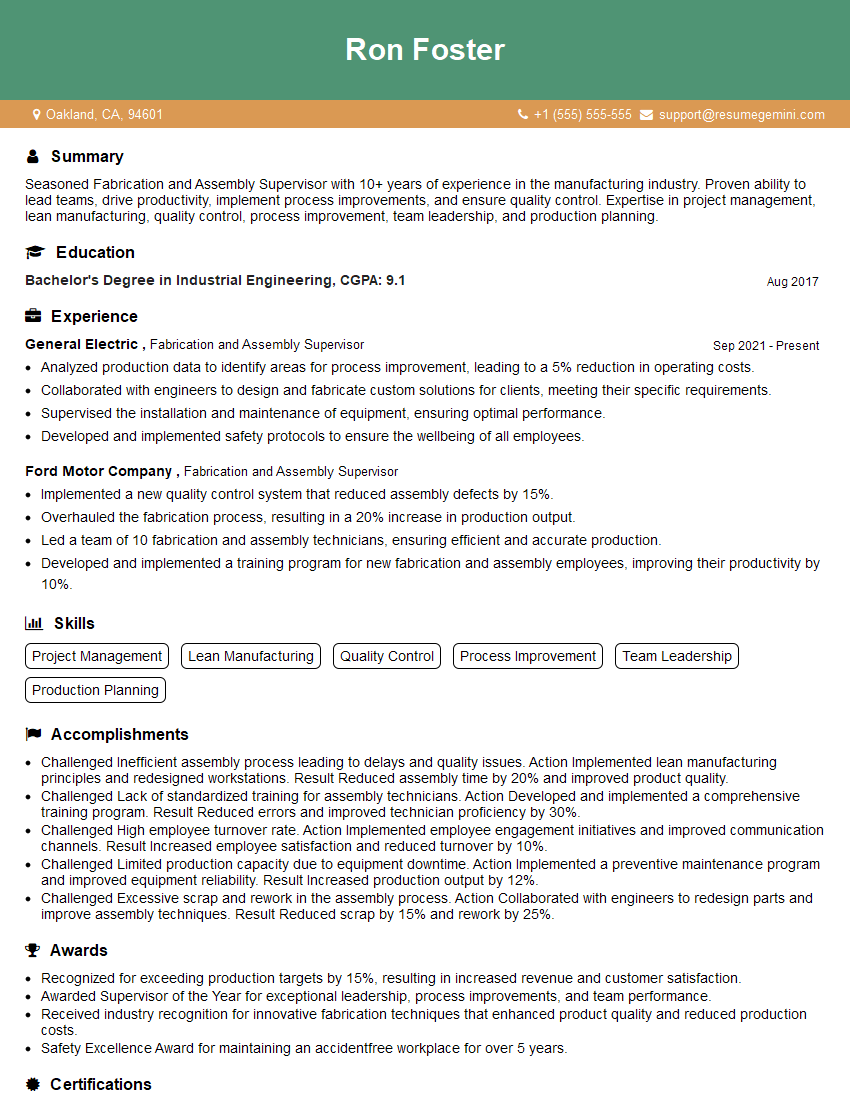

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabrication and Assembly Supervisor

1. Can you describe the process of fabricating a complex assembly, including the use of jigs and fixtures?

- Begin by reviewing the engineering drawings and specifications to ensure a clear understanding of the assembly’s design and requirements.

- Select the appropriate materials based on the specifications and availability.

- Set up the necessary jigs and fixtures to ensure accuracy and repeatability during fabrication.

- Cut and shape the individual components using appropriate tools and equipment, such as CNC machines, laser cutters, or manual tools.

- Assemble the components according to the design, using welding, riveting, or other joining methods.

- Inspect the assembly to verify its dimensions, tolerances, and overall quality.

- Make any necessary adjustments or modifications to meet the specifications.

2. How do you manage a team of assembly technicians and ensure efficient and accurate production?

Supervision and Training

- Provide clear instructions and training to team members on assembly procedures and safety protocols.

- Supervise and monitor their work to ensure they follow the established standards and timelines.

- Identify and address any performance issues promptly, providing guidance and support as needed.

Planning and Coordination

- Plan and coordinate production schedules to optimize efficiency and minimize downtime.

- Ensure the availability of necessary materials, tools, and equipment to support the team’s work.

Quality Control and Improvement

- Establish and implement quality control measures to ensure the accuracy and reliability of assembled products.

- Regularly inspect team members’ work and provide feedback on areas for improvement.

3. What are the key factors to consider when optimizing assembly processes for cost reduction and increased productivity?

- Identify and eliminate waste and inefficiencies in the assembly process.

- Use lean manufacturing principles to streamline operations and improve workflow.

- Implement automation or semi-automation to increase efficiency and reduce labor costs.

- Standardize assembly procedures and use jigs and fixtures to reduce errors and improve consistency.

- Train and empower team members to identify and resolve issues, reducing downtime.

- Monitor and analyze production data to identify areas for improvement and implement changes accordingly.

4. How do you ensure the quality of fabricated and assembled products meet customer specifications and industry standards?

- Establish clear quality control standards and procedures based on customer requirements and industry regulations.

- Implement inspection and testing processes at various stages of fabrication and assembly to identify and correct any defects.

- Use calibrated and certified measuring equipment to ensure accuracy and reliability of measurements.

- Train and certify team members on quality control procedures and ensure they follow them consistently.

- Document and maintain quality records to demonstrate compliance and traceability.

5. Can you describe the importance of safety in a fabrication and assembly environment and how you ensure a safe workplace for your team?

- Establish and maintain a comprehensive safety program that includes hazard identification, risk assessment, and control measures.

- Train and educate team members on safety protocols and ensure they wear appropriate personal protective equipment.

- Regularly inspect the workplace to identify and address potential hazards.

- Implement safety measures such as machine guards, ventilation systems, and emergency procedures.

- Empower team members to report any unsafe conditions or practices and actively encourage a culture of safety awareness.

6. How do you handle deviations or non-conformances during fabrication or assembly and ensure corrective actions are taken effectively?

- Establish clear procedures for reporting and investigating deviations or non-conformances.

- Analyze the root causes of the deviations and identify appropriate corrective actions.

- Implement corrective actions promptly to prevent recurrence and improve processes.

- Document and track the corrective actions taken to demonstrate compliance and continuous improvement.

- Communicate the corrective actions to the team and ensure they are understood and implemented effectively.

7. How do you stay up-to-date with advances in fabrication and assembly technologies and incorporate them into your operations?

- Attend industry trade shows and conferences to learn about new technologies and best practices.

- Read industry publications and technical journals to stay informed about advancements.

- Collaborate with vendors and suppliers to explore new products and solutions.

- Encourage team members to participate in training and development programs to enhance their knowledge and skills.

- Evaluate and pilot new technologies to assess their potential benefits and impact on operations.

8. How do you handle time-sensitive projects with demanding deadlines and ensure they are completed on time and within budget?

- Break down the project into smaller, manageable tasks and assign clear responsibilities to team members.

- Establish a detailed project schedule and monitor progress regularly to identify potential delays.

- Communicate regularly with stakeholders to keep them informed of progress and any challenges encountered.

- Empower team members to make decisions and take ownership of their tasks to expedite the process.

- Identify and address any resource constraints or bottlenecks to ensure timely completion.

9. How do you ensure that your team is motivated and engaged in their work?

- Establish clear goals and expectations for the team and provide regular feedback on their performance.

- Recognize and reward individual and team achievements to foster a culture of appreciation and motivation.

- Provide opportunities for professional development and growth to enhance their skills and knowledge.

- Create a positive and supportive work environment where team members feel valued and respected.

- Encourage open communication and collaboration to foster a sense of belonging and shared purpose.

10. Can you describe a situation where you successfully implemented a new process or technology that significantly improved the efficiency or quality of fabrication or assembly operations?

- Identified an outdated or inefficient process and conducted research to find a better solution.

- Presented the new process to management and obtained approval for implementation.

- Trained the team on the new process and provided ongoing support during the transition.

- Monitored the implementation and made adjustments as needed to optimize its effectiveness.

- Quantified the improvements in efficiency or quality and presented the results to stakeholders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabrication and Assembly Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabrication and Assembly Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fabrication and Assembly Supervisor oversees the daily operations of the fabrication and assembly department, ensuring that all processes are completed efficiently and effectively while maintaining high-quality standards.

1. Production Management

The supervisor is responsible for:

- Planning, scheduling, and coordinating production activities

- Ensuring that all production goals are met within the specified deadlines

- Monitoring production processes to identify and resolve any bottlenecks or inefficiencies

2. Quality Control

The supervisor is responsible for:

- Establishing and maintaining quality control standards

- Inspecting products at various stages of production

- Identifying and correcting any defects or quality issues

3. Team Management

The supervisor is responsible for:

- Leading, motivating, and developing a team of fabrication and assembly workers

- Providing training and technical guidance to team members

- Evaluating team performance and providing feedback

4. Safety and Compliance

The supervisor is responsible for:

- Enforcing safety regulations and guidelines

- Conducting safety inspections and audits

- Ensuring that all employees are trained on safety procedures

Interview Tips

Preparing for an interview for a Fabrication and Assembly Supervisor position requires thorough research, practice, and a positive mindset. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s history, values, products, and services. Research the specific role you are applying for and identify the key responsibilities and qualifications required. This knowledge will help you tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers out loud. This will help you become comfortable with the material and deliver your responses confidently during the interview. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

3. Highlight Your Skills and Experience

Emphasize your technical skills and experience in fabrication and assembly processes. Showcase your knowledge of quality control standards and your ability to lead and motivate a team. Quantify your accomplishments with specific metrics to demonstrate your impact on previous roles.

4. Show Your Passion for Manufacturing

Express your enthusiasm for the manufacturing industry and your commitment to delivering high-quality products. Highlight your understanding of the challenges and opportunities in the field and your willingness to contribute to the success of the company.

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the role and the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabrication and Assembly Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!