Feeling lost in a sea of interview questions? Landed that dream interview for Fabrication Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fabrication Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

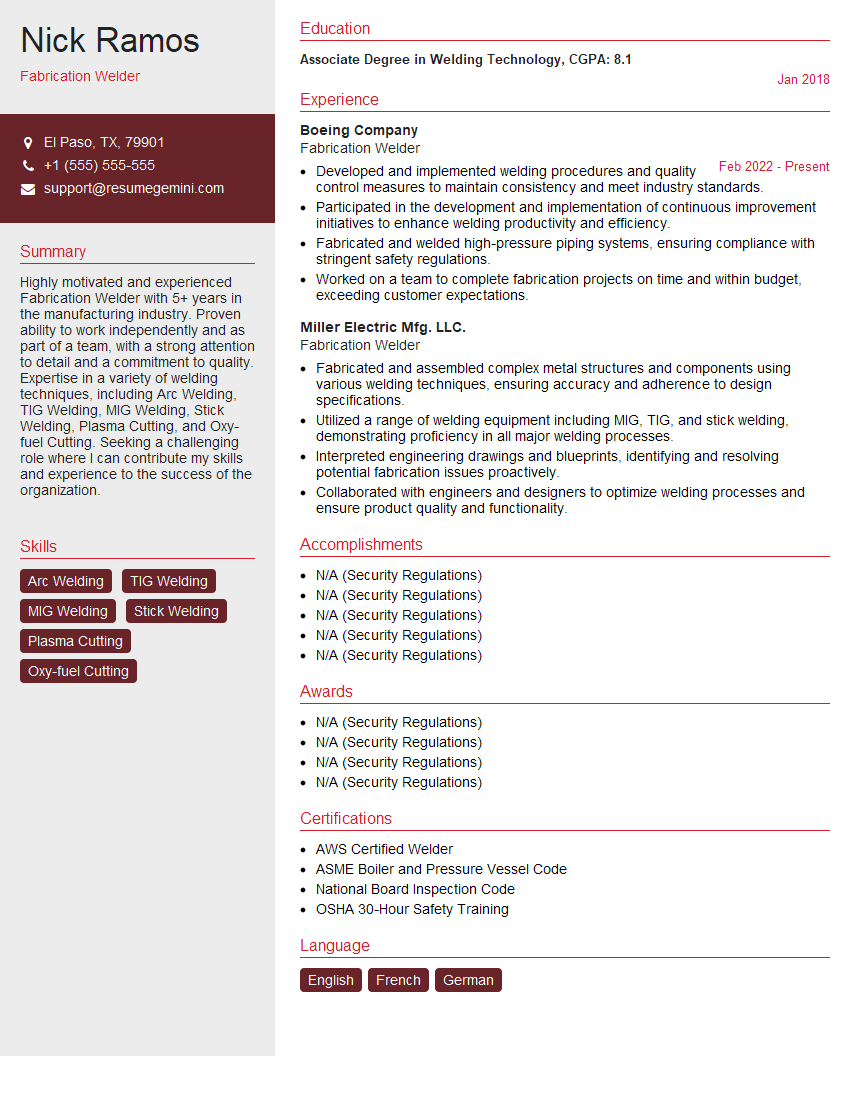

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabrication Welder

1. Describe the different types of welding processes you are familiar with and their applications.

I have experience with various welding processes including:

- Shielded Metal Arc Welding (SMAW), also known as stick welding, is suitable for welding thick materials and outdoor applications.

- Gas Tungsten Arc Welding (GTAW), or TIG welding, provides precise welds with minimal spatter and is ideal for thin materials and exotic metals.

- Gas Metal Arc Welding (GMAW), known as MIG welding, is a semi-automatic process that offers high deposition rates and is widely used in industrial applications.

- Flux-Cored Arc Welding (FCAW) combines the versatility of MIG welding with the self-shielding properties of flux-cored wire, making it suitable for outdoor and heavy-duty applications.

2. What are the key considerations when selecting welding parameters for a specific fabrication project?

Material Properties:

- Thickness and composition of the materials being welded

- Melting point and thermal conductivity

Joint Design:

- Type of joint (e.g., butt joint, lap joint)

- Fit-up and edge preparation

Welding Process:

- Type of welding process (e.g., SMAW, GTAW)

- Welding current, voltage, and travel speed

Environmental Factors:

- Wind speed and shielding gas availability

- Temperature and humidity

3. How do you ensure the quality of your welds and meet industry standards?

- Follow established welding procedures and specifications

- Inspect welds visually to assess bead appearance, penetration, and surface imperfections

- Perform destructive and non-destructive testing (e.g., radiography, ultrasonic testing) to verify weld integrity

- Maintain welding equipment and consumables in good condition

- Stay up-to-date with industry best practices and advancements

4. Describe the importance of proper joint preparation and fit-up for successful welding.

- Ensures proper penetration and fusion of the weld metal

- Reduces the risk of weld defects such as porosity, slag inclusions, and undercut

- Improves the overall strength, durability, and appearance of the weld

- Minimizes welding time and material waste

5. What is the purpose of preheat and post-weld heat treatment in welding?

Preheat:

- Reduces the risk of cracking in high-strength and alloy steels

- Improves weldability and reduces residual stresses

Post-Weld Heat Treatment:

- Stress relieves the weld and surrounding material

- Improves toughness and ductility

- Enhances mechanical properties and reduces the risk of brittle fracture

6. What are the potential hazards associated with welding and how can they be minimized?

- Electric shock: Use proper insulation and grounding procedures

- Eye injuries: Wear appropriate eye protection and welding helmets

- Fumes and gases: Ventilate the workspace and use respirators

- Fire and explosion: Keep flammable materials away and have fire extinguishers readily available

- Noise: Use hearing protection

7. How do you stay abreast of advancements and best practices in welding technology?

- Attend industry conferences and seminars

- Read technical publications and journals

- Participate in online forums and discussion groups

- Seek professional development opportunities

- Network with other welders and industry professionals

8. Describe your experience with reading and interpreting welding blueprints and specifications.

- Familiar with symbols and conventions used in welding drawings

- Can interpret welding specifications and determine joint design, materials, and welding parameters

- Follow instructions and dimensions precisely to ensure accurate fabrication

9. What is the importance of maintaining a clean and organized work area in welding?

- Reduces the risk of accidents and injuries

- Improves welding efficiency and productivity

- Protects equipment and materials from damage

- Creates a professional and positive work environment

10. How do you handle challenging situations or unexpected issues that arise during welding?

- Problem identification: Assess the situation and determine the cause of the issue

- Solution development: Explore different options and consult with colleagues or supervisors

- Implementation: Implement the appropriate solution and verify its effectiveness

- Documentation: Record the issue, solution, and any lessons learned for future reference

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabrication Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabrication Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabrication Welders are skilled professionals who play a vital role in the fabrication industry. They use specialized welding techniques to create and repair metal components, structures, and products.

1. Welding Operations

Welding is the core responsibility of a Fabrication Welder. They use various welding processes, including MIG, TIG, and stick welding, to join metal pieces securely. They must have a deep understanding of welding parameters, such as amperage, voltage, and travel speed, to achieve optimal weld quality.

- Select and prepare welding materials, including welding rods, wires, and fluxes.

- Set up and operate welding equipment.

- Inspect and test welds to ensure they meet specifications.

2. Fabrication and Assembly

Fabrication Welders often work with other tradespeople to assemble complex structures and products. They may be involved in cutting, shaping, and fitting metal pieces prior to welding. They must have a good understanding of fabrication techniques and the ability to work accurately and efficiently.

- Read and interpret blueprints and drawings.

- Cut and shape metal pieces using tools such as grinders, drills, and saws.

- Assemble and fit metal components using welding and other techniques.

3. Quality Control

Fabrication Welders are responsible for ensuring the quality of their work. They must adhere to strict welding standards and industry regulations. They may be required to perform non-destructive testing methods, such as visual inspection, dye penetrant testing, and ultrasonic testing, to evaluate the integrity of welds.

- Follow welding procedures and specifications.

- Perform quality checks on welds using visual inspection and testing methods.

- Document welding operations and maintain quality records.

4. Safety and Compliance

Fabrication Welders work with hazardous materials and equipment. They must follow strict safety protocols to prevent accidents and injuries. They must also comply with environmental and regulatory guidelines related to welding operations.

- Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE), such as welding helmets, gloves, and flame-resistant clothing.

- Handle and store welding materials and equipment safely.

Interview Tips

Preparing thoroughly for a Fabrication Welder interview can increase your chances of success. Here are some tips to help you:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific job position. Learn about their products or services, industry trends, and company culture. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the company.

- Visit the company’s website.

- Read industry publications.

- Practice answering common interview questions specific to Fabrication Welders.

2. Highlight Your Skills and Experience

Be prepared to discuss your welding skills and experience in detail. Emphasize your proficiency in various welding processes and your ability to work with different types of metals. Highlight any relevant certifications or training you have obtained.

- Provide specific examples of your welding projects.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your knowledge of welding standards and regulations.

3. Emphasize Safety and Quality

Fabrication Welders must prioritize safety and quality in their work. In your interview, emphasize your commitment to following safety protocols and adhering to welding standards. Highlight any experience you have with quality control and inspection techniques.

- Explain your understanding of the importance of safety in welding operations.

- Describe your experience with quality control and inspection methods.

- Provide examples of how you have ensured the quality of your welds.

4. Practice Your Answers

Practice answering common interview questions to build your confidence and improve your delivery. Prepare for questions about your welding skills, experience, safety practices, and career goals. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Use the STAR method to answer questions about your welding projects.

- Practice answering questions about safety and quality control.

- Be prepared to talk about your career goals and how they align with the company’s needs.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabrication Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!