Are you gearing up for a career in Fabricator Assembler Metal Products? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fabricator Assembler Metal Products and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

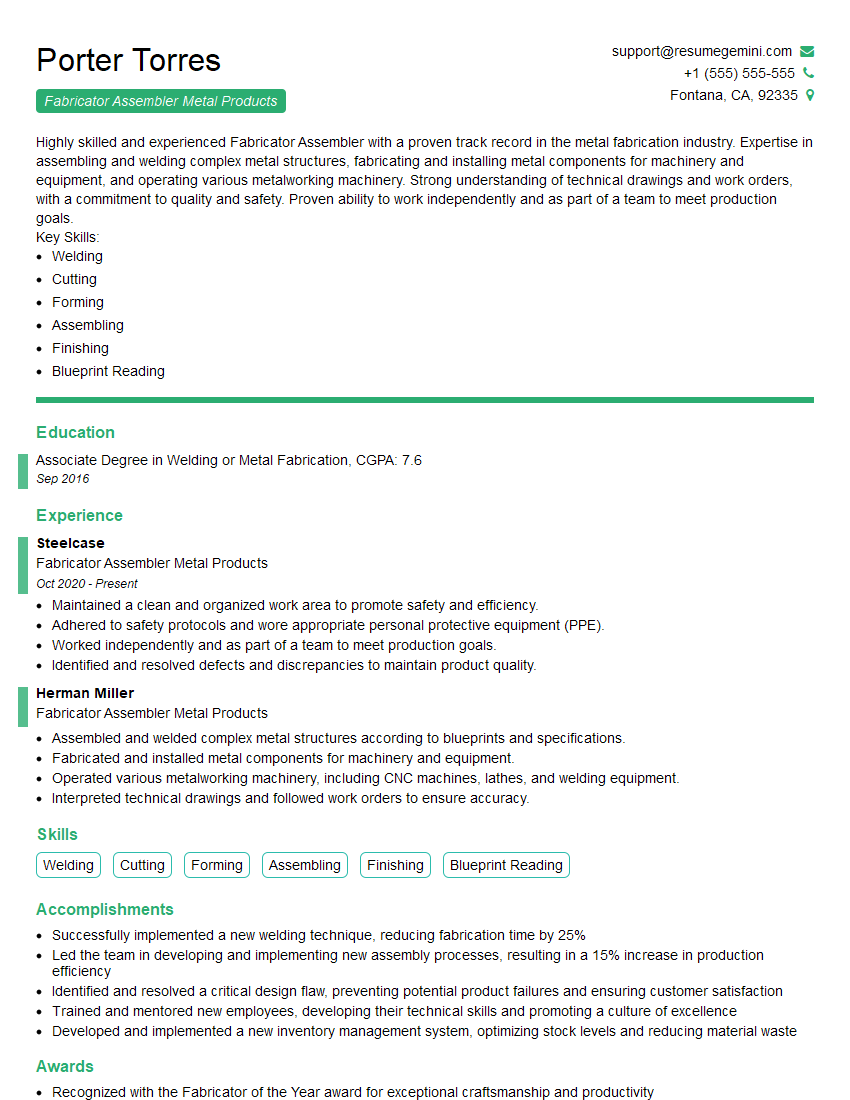

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabricator Assembler Metal Products

1. What is the difference between brazing and welding?

- Brazing is a metal-joining process that uses a filler metal that has a lower melting point than the base metal. The filler metal flows into the joint by capillary action, and the bond is formed by the interdiffusion of the base and filler metals.

- Welding is a metal-joining process that uses heat to melt the base metal and the filler metal. The molten metal flows together to form a bond.

2. What are the different types of welding processes?

Arc Welding

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

Resistance Welding

- Spot Welding

- Seam Welding

- Projection Welding

Solid-State Welding

- Ultrasonic Welding

- Friction Welding

- Explosive Welding

3. What are the different types of metal fabrication processes?

- Cutting

- Bending

- Forming

- Joining

- Finishing

4. What are the different types of metal finishes?

- Paints

- Powders

- Electroplating

- Anodizing

- Conversion Coatings

5. What are the different types of metalworking equipment?

- Lathes

- Mills

- Drills

- Presses

- Saws

6. What are the different types of metalworking materials?

- Iron

- Steel

- Aluminum

- Copper

- Titanium

7. What are the different types of metalworking safety hazards?

- Cuts

- Burns

- Eye injuries

- Hearing loss

- Respiratory problems

8. What are the different types of metalworking quality control checks?

- Dimensional inspections

- Visual inspections

- Non-destructive testing

- Destructive testing

- Statistical process control

9. What are the different types of metalworking industry sectors?

- Automotive

- Aerospace

- Medical

- Construction

- Energy

10. What are the different types of metalworking career paths?

- Fabricator

- Welder

- Machinist

- Tool and Die Maker

- Quality Control Inspector

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabricator Assembler Metal Products.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabricator Assembler Metal Products‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fabricator Assembler Metal Products is a sought-after role in the manufacturing industry. In this position, the successful candidate will be responsible for the fabrication and assembly of metal products, ensuring that all components meet the required specifications and standards.

1. Crafting and Assembling Metal Products:

The primary responsibility of this role is to fabricate and assemble metal products according to blueprints, specifications, and industry standards.

- Reading and interpreting blueprints, technical drawings, and schematics

- Operating various fabrication and assembly equipment, such as drills, grinders, welding machines, and presses

- Cutting, shaping, and welding metal components to create complete products

- Assembling and fitting components together to form functional assemblies

- Inspecting and testing assemblies to ensure dimensional accuracy and structural integrity

2. Operating Equipment and Machinery:

Thorough knowledge of machinery and equipment is essential for the role.

- Proficiently operating cutting, shaping, and welding equipment

- Calibrating and maintaining equipment to ensure accuracy and safety

- Following established safety protocols and procedures

3. Quality Control and Inspection:

The candidate should demonstrate a commitment to quality and precision.

- Inspecting and testing metal products to ensure they meet specifications

- Identifying and rectifying defects and discrepancies

- Maintaining accurate records and documentation of inspections

4. Teamwork and Communication:

Collaboration and effective communication are key in this role.

- Collaborating with engineers, designers, and other team members

- Communicating clearly and effectively about project progress and issues

- Working in a fast-paced and demanding production environment

Interview Tips

Preparing thoroughly for the interview can significantly increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position:

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and the scope of the role.

- Visit the company website and social media pages.

- Review the job description carefully.

- Check industry news and articles to stay up-to-date on the company’s recent developments.

2. Practice Your Answers:

Prepare thoughtful and well-structured answers to common interview questions. This will help you articulate your skills, experiences, and why you’re the right candidate for the job.

- Practice answering questions about your technical skills, experience with metal fabrication and assembly, and quality control procedures.

- Explain why you’re interested in the position and how your skills and qualifications align with the company’s needs.

- Prepare specific examples of your accomplishments and how they demonstrate your abilities.

3. Dress Professionally and Arrive on Time:

First impressions matter. Dress professionally and arrive on time for your interview. This shows the interviewer that you respect their time and that you’re serious about the opportunity.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Plan your route and leave early to allow for unexpected delays.

- Arrive a few minutes early to relax and compose yourself before the interview.

4. Be Enthusiastic and Confident:

Convey enthusiasm and confidence during your interview. This will help you make a positive impression and demonstrate your passion for the role.

- Smile, make eye contact, and speak clearly.

- Use positive body language, such as maintaining an upright posture and nodding in agreement.

- Be confident in your abilities and experience, but avoid being arrogant or overbearing.

5. Ask Thoughtful Questions:

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the opportunity. It also gives you an opportunity to clarify any details or ask about the company culture.

- Prepare questions about the company’s growth plans, the team you’d be working with, and the training and development opportunities available.

- Ask about the company’s values and how they align with your own.

- Inquire about the next steps in the hiring process and when you can expect to hear back.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabricator Assembler Metal Products interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!