Feeling lost in a sea of interview questions? Landed that dream interview for Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

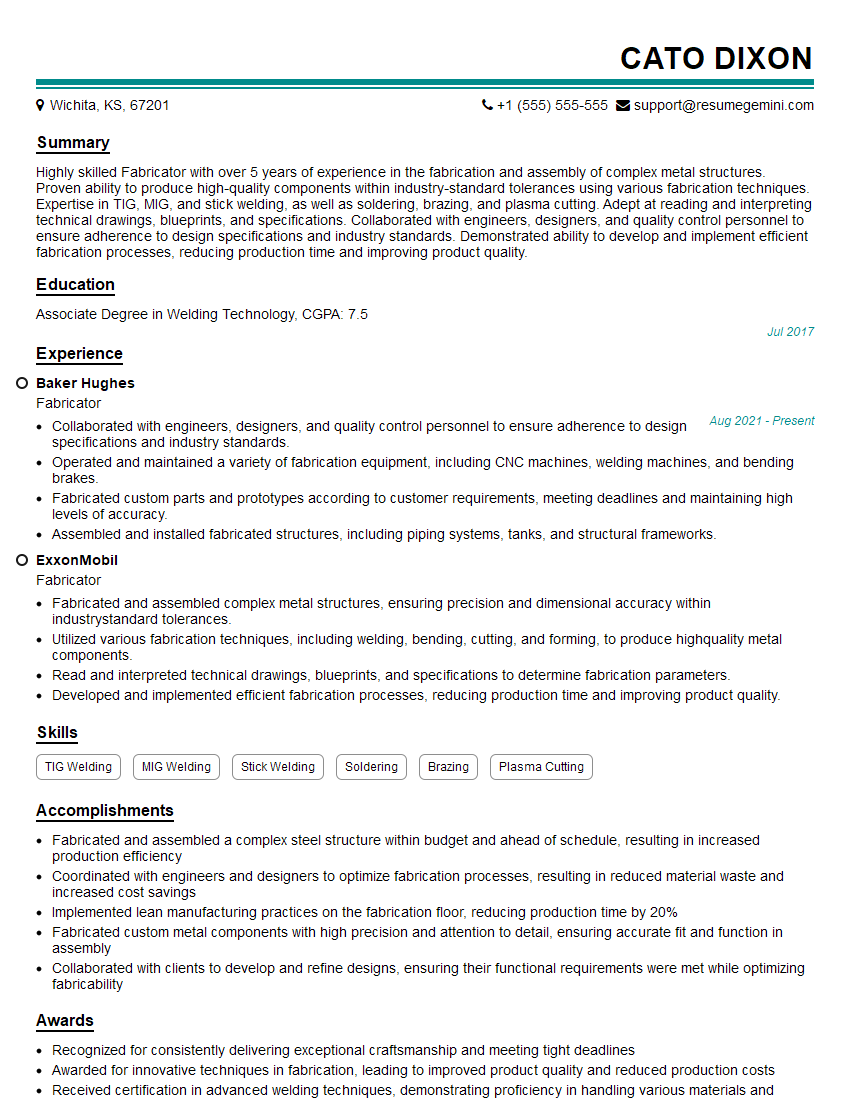

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabricator

1. What are the different types of fabrication processes you are familiar with?

I have experience in a wide range of fabrication processes, including:

- Welding (MIG, TIG, stick)

- Cutting (plasma, laser, waterjet)

- Bending

- Rolling

- Stamping

- Machining

2. What are the most important safety precautions to take when working in a fabrication shop?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including safety glasses, gloves, hearing protection, and a respirator when necessary.

- Inspect PPE regularly for damage and replace as needed.

Tool Safety

- Use tools only for their intended purpose.

- Inspect tools regularly for damage and repair or replace as needed.

- Never use damaged or unsafe tools.

Work Environment

- Keep the work area clean and organized.

- Be aware of potential hazards such as electrical wires, sharp edges, and moving equipment.

- Follow established safety procedures and protocols.

3. What is your experience with reading and interpreting engineering drawings?

I have extensive experience reading and interpreting engineering drawings. I am proficient in using AutoCAD and other CAD software to create and modify drawings. I can also interpret complex drawings and specifications to ensure that fabricated parts meet the required tolerances and specifications.

4. What quality control procedures do you follow to ensure the accuracy and precision of fabricated parts?

- Inspect raw materials upon arrival to ensure they meet specifications.

- Follow established quality control procedures during fabrication to identify and correct any deviations.

- Use precision measuring tools to ensure parts meet the required tolerances.

- Conduct final inspections before parts are shipped to ensure they meet customer requirements.

- Maintain records of all quality control inspections for traceability purposes.

5. What is your experience with working in a fast-paced manufacturing environment?

I have worked in fast-paced manufacturing environments for over 5 years. I am accustomed to working under pressure and meeting tight deadlines. I am also able to prioritize tasks and work independently or as part of a team to achieve project goals.

6. What is your experience with using CNC machines?

I have experience using various CNC machines, including CNC mills, lathes, and plasma cutters. I am proficient in programming and operating CNC machines to produce complex parts according to specifications. I am also able to troubleshoot and maintain CNC machines to ensure optimal performance.

7. What are your strengths and weaknesses as a fabricator?

Strengths

- Strong technical skills and knowledge of fabrication processes

- Excellent attention to detail and commitment to quality

- Ability to work independently and as part of a team

- Good problem-solving skills

- Strong work ethic and willingness to learn new things

Weaknesses

- Limited experience with some specialized fabrication techniques

- Can be somewhat perfectionistic at times

8. Why are you interested in working for our company?

I am interested in working for your company because of its reputation for producing high-quality fabricated products. I am also impressed by your company’s commitment to customer satisfaction and employee development. I believe that my skills and experience would be a valuable asset to your team, and I am eager to contribute to the success of your company.

9. What are your salary expectations?

My salary expectations are commensurate with my skills and experience. I am confident that I can bring value to your company and am open to discussing a salary that is competitive within the industry.

10. Do you have any questions for me?

Yes, I have a few questions:

- Can you tell me more about the specific fabrication processes used in your company?

- What are the company’s quality standards and how are they maintained?

- What opportunities for professional development are available to employees?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fabricators are skilled craftspeople who play a crucial role in manufacturing processes. They create and assemble metal structures and components for various industries, including construction, automotive, and aerospace.

1. Fabricating Metal Structures

Fabricators are responsible for creating metal structures from scratch or following blueprints and specifications. They use various fabrication techniques, such as cutting, welding, bending, and assembling, to produce high-quality and durable metal products.

- Interpret blueprints and technical drawings

- Select appropriate materials and fabrication methods

2. Welding and Joining

Fabricators use different welding techniques, such as MIG, TIG, and arc welding, to join metal components together. They must ensure that welds are strong, durable, and meet industry standards.

- Operate welding equipment

- Inspect and test welds for quality

3. Bending and Forming

Fabricators use bending and forming techniques to shape metal into desired shapes and angles. They may use manual or automated machines to perform these operations.

- Operate bending and forming machines

- Ensure accurate bending and forming angles

4. Assembling and Installing

Fabricators assemble and install fabricated metal components into final products or structures. They use bolts, screws, and other fasteners to secure the components.

- Assemble and install metal components

- Inspect and test final products

Interview Tips

Preparing for a fabricator interview requires understanding the key job responsibilities, researching the industry, and practicing your answers. Here are some tips to help you ace your interview:

1. Research the Company and Role

Thoroughly research the company and the specific fabrication role you’re applying for. Familiarize yourself with their products, services, and industry reputation. Understanding the company’s needs will help you tailor your answers and demonstrate your fit for the position.

- Visit the company’s website and social media profiles

- Read industry news and articles about the company

2. Highlight Your Skills and Experience

In your resume and during the interview, highlight your relevant skills and experience. Employers seek fabricators with strong technical abilities, such as welding, fabrication, and assembly. Quantify your accomplishments and provide specific examples of your work.

- Showcase your proficiency in welding techniques

- Emphasize your experience in fabricating metal structures

3. Prepare for Technical Questions

Expect technical questions during the interview. Be prepared to discuss your knowledge of fabrication techniques, materials, and industry standards. Employers may ask about your experience with specific equipment or processes.

- Review different welding methods

- Familiarize yourself with metal types and their properties

4. Ask Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s culture, growth opportunities, and the specific role you’re applying for.

- Inquire about training and development opportunities

- Ask about the company’s safety policies and procedures

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!