Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fabrics and Material Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

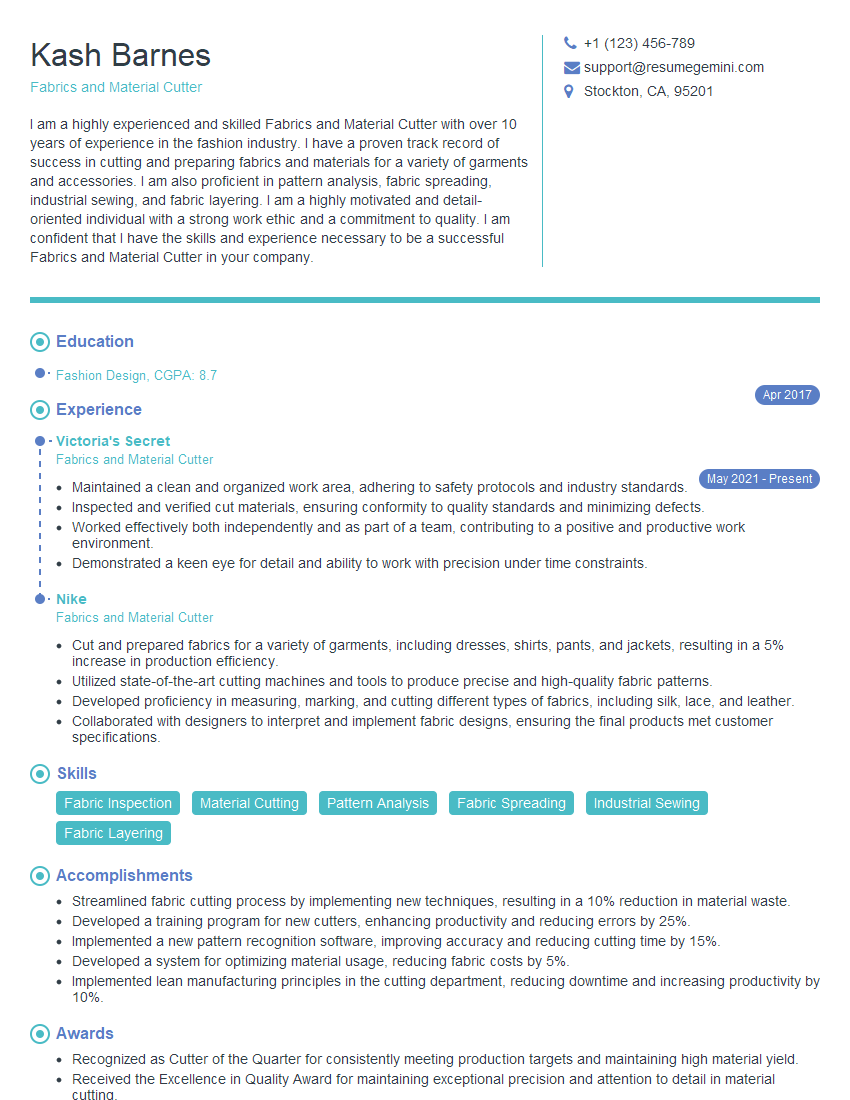

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabrics and Material Cutter

1. What different types of fabrics have you worked with?

In my previous role, I have worked with various types of fabrics, including natural fibers such as cotton, linen, and silk, as well as synthetic materials like polyester, nylon, and spandex.

2. Can you describe the process of cutting fabric?

Measuring and Marking

- Read the cutting instructions carefully.

- Measure and mark the fabric using a measuring tape, ruler, or yard stick.

- Use a fabric marker or chalk to mark the cutting lines.

Cutting

- Choose the appropriate cutting tool for the fabric.

- Follow the marked cutting lines precisely.

- Cut the fabric smoothly and evenly.

3. What are the different types of cutting tools used in fabric cutting?

Fabric cutting tools include rotary cutters, scissors, shears, and utility knives. Rotary cutters are ideal for cutting large pieces of fabric, while scissors are best for cutting smaller pieces or making intricate cuts. Shears are used for heavy-duty cutting, and utility knives are versatile tools that can be used for a variety of cutting tasks.

4. How do you ensure accuracy in fabric cutting?

- Use sharp cutting tools.

- Measure and mark the fabric carefully.

- Follow the cutting lines precisely.

- Double-check the measurements before cutting.

- Use a cutting mat to provide a stable surface.

5. What safety precautions should be taken when cutting fabric?

- Wear safety glasses to protect your eyes from flying fabric particles.

- Keep your fingers away from the cutting blade.

- Use a sharp cutting tool to avoid ragged edges.

- Cut on a stable surface to prevent the fabric from shifting.

- Dispose of fabric scraps properly to avoid tripping hazards.

6. How do you handle different types of fabrics that require special care?

Delicate fabrics, such as silk or lace, require special care during cutting. I use sharp scissors and handle the fabric gently to avoid snags or tears. For stretchy fabrics, I use a rotary cutter with a guide to ensure straight and even cuts. I also take into consideration the grain of the fabric to prevent distortion during sewing.

7. Can you describe the process of pattern cutting?

- Transfer the pattern pieces onto the fabric.

- Cut out the pattern pieces carefully, following the cutting lines.

- Match and pin the pattern pieces together.

- Sew the pattern pieces together according to the pattern instructions.

8. What techniques do you use to minimize fabric waste?

- Plan the cutting layout carefully.

- Use nesting techniques to fit multiple pattern pieces onto the fabric.

- Reuse fabric scraps for smaller projects or embellishments.

- Donate leftover fabric to organizations or individuals who can use it.

9. Can you describe your experience with different types of sewing machines?

I am proficient in operating various types of sewing machines, including industrial machines, home sewing machines, and sergers. I am comfortable with basic sewing techniques, such as straight stitching, zigzag stitching, and buttonhole making. Additionally, I have experience in using specialized techniques, such as blind hemming, topstitching, and free-motion embroidery.

10. What software or tools do you use to aid in fabric cutting?

I am familiar with using computer-aided design (CAD) software for pattern creation and grading. I also use digital cutting machines to ensure precise and efficient fabric cutting. These tools help me maximize fabric utilization, reduce waste, and improve the overall quality of my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabrics and Material Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabrics and Material Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fabrics and Material Cutter holds the primary responsibility for cutting and preparing fabrics and other materials used in the production of various products, ensuring precision and efficiency in the manufacturing process.

1. Fabric Cutting

Using specialized cutting machines and equipment, they cut fabrics and materials into precise shapes and sizes according to specified patterns and designs.

- Select appropriate cutting tools and techniques based on fabric type and project requirements.

- Measure, mark, and cut fabrics accurately using rulers, measuring tapes, and other tools.

2. Material Preparation

Prepare materials by ironing, stretching, or treating them to enhance their quality and suitability for cutting and sewing.

- Remove wrinkles and creases from fabrics by ironing or steaming.

- Stretch fabrics to ensure proper tension and alignment during cutting.

3. Pattern Matching

Match fabric patterns precisely during cutting to ensure continuity and consistency in the finished product.

- Align and match patterns for plaids, stripes, and other complex designs.

- Follow cutting instructions and specifications to ensure pattern accuracy.

4. Quality Control

Inspect cut fabrics and materials for defects, ensuring they meet quality standards before passing them on for further processing.

- Identify and reject fabrics with flaws or imperfections.

- Maintain cutting accuracy and consistency to minimize waste and production errors.

Interview Tips

To ace the interview for a Fabrics and Material Cutter position, candidates should prepare thoroughly and showcase their skills and experience in a professional and confident manner. Here are some helpful tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and values. Research the specific role and its responsibilities to demonstrate your interest and understanding of the position.

- Visit the company’s website and social media pages.

- Read industry articles and news to stay informed about trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in cutting and preparing fabrics and materials, as well as your attention to detail and precision. Share specific examples of projects where you successfully cut and matched patterns accurately.

- Quantify your accomplishments with specific numbers and metrics.

- Use action verbs to describe your responsibilities and results.

3. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself” and “Why are you interested in this role?” Practice your answers aloud to develop clear and concise responses.

- Consider using the STAR method to answer behavioral questions.

- Tailor your answers to the specific job description.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your genuine interest and engagement. Prepare questions about the company’s cutting processes, quality control measures, or training opportunities.

- Avoid asking questions about salary or benefits at this stage.

- Questions that demonstrate your curiosity and enthusiasm are encouraged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fabrics and Material Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!