Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Factory Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

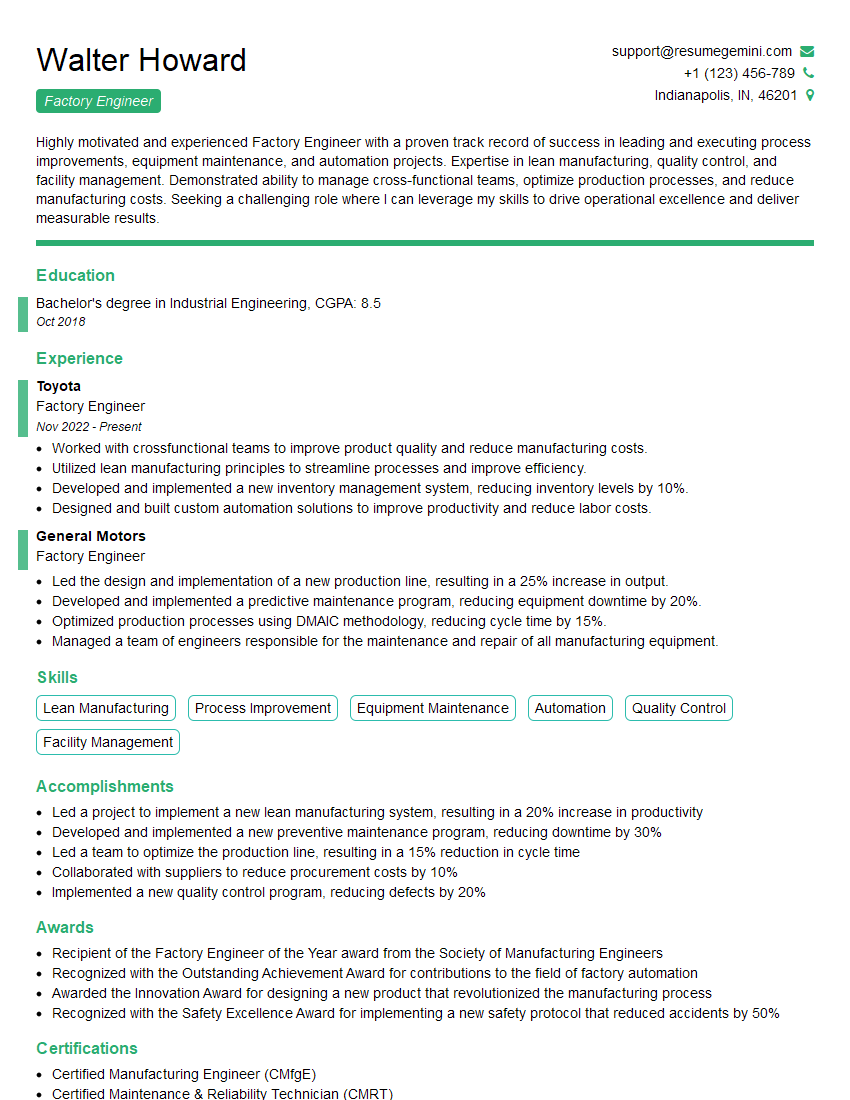

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Factory Engineer

1. What are some of the safety measures that you follow in a production environment?

- Maintain a clean and organized work area.

- Wear appropriate safety gear, such as hard hats, safety glasses, and gloves.

- Be aware of potential hazards and take steps to avoid them.

- Follow established safety procedures.

- Report any unsafe conditions or practices to management.

2. What is your experience with lean manufacturing techniques?

Benefits of Lean Manufacturing Techniques

- Reduced waste

- Improved efficiency

- Increased productivity

- Improved quality

- Reduced costs

Experience with Lean Manufacturing Techniques

- Implemented a 5S program to improve workplace organization.

- Used value stream mapping to identify and eliminate waste.

- Reduced setup times through the use of quick-changeover techniques.

- Developed and implemented a preventive maintenance program to improve equipment reliability.

- Trained employees on lean manufacturing principles and techniques.

3. How do you ensure the quality of products manufactured in your facility?

- Develop and implement quality control procedures.

- Monitor and inspect products throughout the manufacturing process.

- Use statistical process control techniques to identify and correct problems.

- Provide training to employees on quality control procedures.

- Work with suppliers to ensure the quality of incoming materials.

4. What are some of the challenges you have faced in your previous role as a Factory Engineer?

- Improving production efficiency.

- Reducing costs.

- Ensuring the quality of products manufactured.

- Developing and implementing new manufacturing processes.

- Managing a team of engineers.

5. What are your strengths and weaknesses as a Factory Engineer?

Strengths

- Strong technical skills.

- Experience with lean manufacturing techniques.

- Proven ability to improve production efficiency and reduce costs.

- Excellent communication and interpersonal skills.

- Ability to work independently and as part of a team.

Weaknesses

- Limited experience with some aspects of factory engineering.

- Tendency to be detail-oriented.

- Can be impatient at times.

6. What are your salary expectations?

This is a difficult question to answer, as salary expectations can vary depending on a number of factors, such as experience, skills, and location. However, I am confident that I can provide value to your company and am willing to negotiate a fair salary.

7. What are your career goals?

- To become a Factory Manager.

- To lead a team of engineers in developing and implementing new manufacturing processes.

- To help my company achieve its production goals.

- To make a positive impact on the manufacturing industry.

8. Why are you interested in working for our company?

- I am impressed by your company’s commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn and grow in a challenging and rewarding environment.

9. What is your availability to start work?

I am available to start work immediately.

10. Do you have any questions for me?

- What are the biggest challenges facing the manufacturing industry today?

- What is your company’s strategy for addressing these challenges?

- What are the opportunities for career advancement within your company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Factory Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Factory Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Factory Engineers are responsible for the smooth and efficient operation of a production facility. They play a crucial role in optimizing production processes, ensuring product quality, and maximizing productivity. Key job responsibilities include:

1. Production Planning and Scheduling

Develop production plans and schedules to ensure timely and efficient production.

- Determine production requirements based on customer orders and forecasts.

- Allocate resources, including equipment, materials, and labor, to optimize production.

2. Process Improvement and Optimization

Identify and implement process improvements to increase efficiency and reduce costs.

- Analyze production processes to identify bottlenecks and inefficiencies.

- Design and implement solutions to improve workflow, reduce waste, and enhance productivity.

3. Equipment Maintenance and Repair

Ensure the proper maintenance and repair of production equipment to minimize downtime.

- Develop and implement preventive maintenance plans to prevent equipment breakdowns.

- Troubleshoot and repair equipment issues to minimize production disruptions.

4. Quality Control and Inspection

Establish and monitor quality control standards to ensure product quality.

- Develop quality control procedures and inspection checklists.

- Inspect products at various stages of production to ensure they meet specifications.

Interview Tips

To ace a Factory Engineer interview, it is important to demonstrate your technical skills, as well as your ability to troubleshoot, manage projects, and work effectively in a team.

1. Research the Company and Position

Take the time to research the company and the specific Factory Engineer position you are applying for. This will allow you to tailor your answers to the company’s needs and show that you have a genuine interest in the role.

- Visit the company’s website to learn about their business, products, and culture.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in manufacturing.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview.

- Tell me about your experience in factory engineering.

- What are your strengths and weaknesses as a Factory Engineer?

- How do you approach process improvement?

- What is your experience with quality control and inspection?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Factory Engineer position. Use specific examples to demonstrate your abilities.

- If you have experience in implementing process improvements, share a specific example of how you improved efficiency or reduced costs.

- If you have experience in quality control, describe your role in developing and implementing quality control procedures.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Plan your route to the interview location in advance to avoid getting lost or running late.

5. Ask Thoughtful Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. Prepare a few thoughtful questions that show you are engaged and interested in the opportunity.

- What are the biggest challenges facing the company right now?

- What are the opportunities for professional development within the company?

- What is the company’s culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Factory Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!