Are you gearing up for an interview for a Factory Expert position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Factory Expert and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

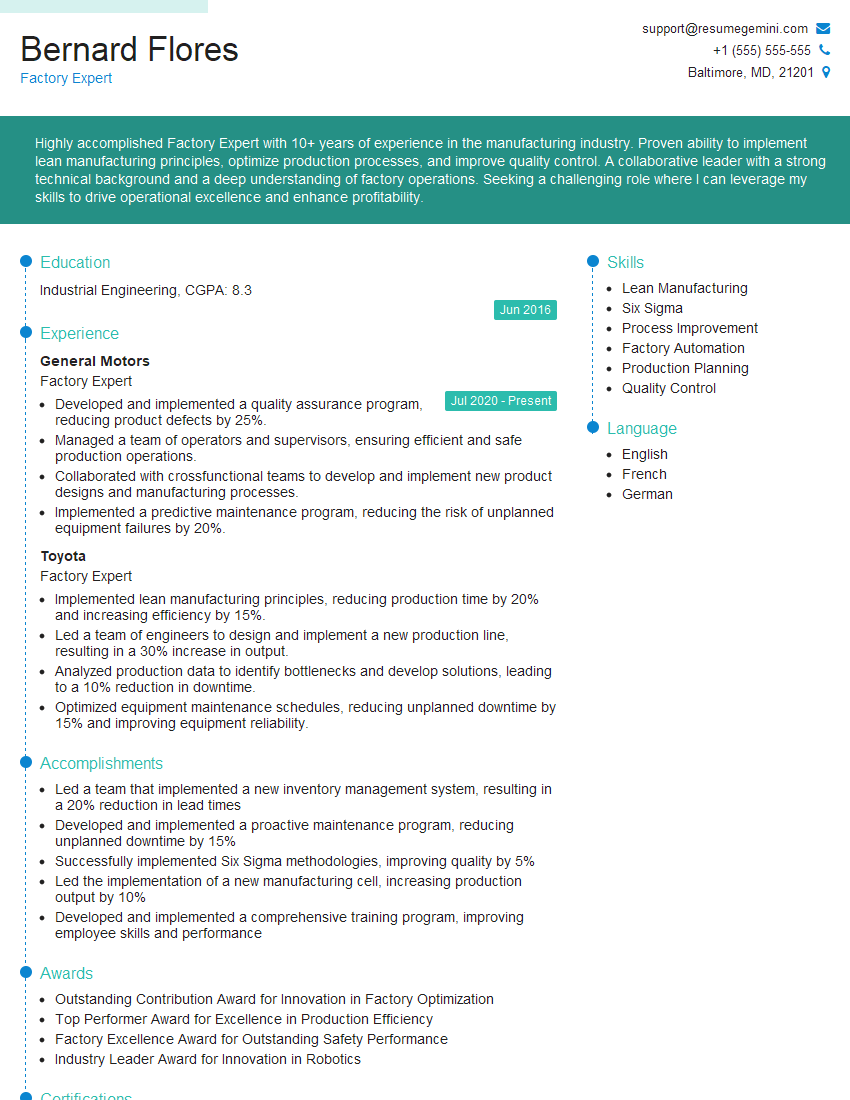

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Factory Expert

1. Describe the key performance indicators (KPIs) you would use to measure the effectiveness of a manufacturing process?

KPIs I would use to measure the effectiveness of a manufacturing process include:

- Overall Equipment Effectiveness (OEE): Measures the efficiency, availability, and quality of manufacturing equipment.

- First-Pass Yield: Indicates the percentage of products passing inspection the first time, reducing rework and waste.

- Production Takt Time: Assesses the pace of production, ensuring a steady flow and minimizing downtime.

- Manufacturing Cycle Time: Measures the time it takes a product to move through the manufacturing process.

- Downtime and Scrap Rate: Quantifies the time lost due to equipment failures and the number of defective products produced.

2. How would you approach improving the efficiency of a production line?

Process Analysis and Optimization

- Identify and eliminate bottlenecks and inefficiencies.

- Streamline production flow and reduce cycle times.

- Implement lean manufacturing principles and continuous improvement.

Equipment Maintenance and Upgrading

- Establish a preventive maintenance program to minimize equipment failures.

- Invest in new or upgraded equipment to improve productivity and accuracy.

- Implement automation and robotics to enhance efficiency.

3. What techniques would you use to ensure product quality and consistency?

To ensure product quality and consistency, I would employ the following techniques:

- Statistical Process Control (SPC): Monitor and analyze production data to identify and control sources of variation.

- Quality Assurance Inspections: Conduct regular inspections at various stages of the production process to detect defects.

- Supplier Management: Establish and maintain relationships with reliable suppliers to ensure the quality of raw materials and components.

- Operator Training and Certification: Provide comprehensive training to ensure operators understand and follow quality standards.

- Root Cause Analysis: Investigate and address the underlying causes of quality issues to prevent recurrence.

4. How would you handle a situation where there is a conflict between production targets and quality standards?

In the event of a conflict between production targets and quality standards, I would prioritize the following steps:

- Communicate and Analyze: Discuss the situation with stakeholders to fully understand the conflicting requirements.

- Assess Risks: Evaluate the potential consequences of sacrificing quality for production or vice versa.

- Explore Alternatives: Seek alternative solutions that meet both quality and production goals.

- Negotiate Priorities: Negotiate with management to establish clear priorities, considering the long-term impact on product reputation and customer satisfaction.

- Implement Corrective Actions: Identify and implement measures to address the underlying causes of the conflict.

5. How would you stay up-to-date with the latest advancements in manufacturing technology?

To stay up-to-date with the latest advancements in manufacturing technology, I would:

- Attend Industry Events and Conferences: Participate in industry conferences, trade shows, and workshops to learn about new technologies and trends.

- Read Technical Publications and Journals: Subscribe to industry magazines, journals, and newsletters to stay informed about research and development.

- Engage in Online Learning: Utilize online courses, webinars, and certification programs to expand my knowledge and skills.

- Join Professional Organizations: Actively participate in professional organizations, such as the Institute of Industrial Engineers (IIE), to connect with experts and stay abreast of industry advancements.

- Collaborate with Vendors: Maintain relationships with equipment and technology vendors to gain insights into new solutions and innovations.

6. What are the key elements of a successful lean manufacturing implementation?

The key elements of a successful lean manufacturing implementation include:

- Employee Engagement: Involve employees at all levels in the process to gain buy-in and foster a culture of continuous improvement.

- Value Stream Mapping: Analyze and streamline production processes to eliminate waste and create value for customers.

- Just-in-Time Production: Reduce inventory levels and enhance efficiency by producing only what is needed, when it is needed.

- Cellular Manufacturing: Group similar operations together to minimize movement and improve productivity.

- Continuous Improvement: Establish a culture of ongoing kaizen activities to identify and eliminate inefficiencies and improve quality.

7. How would you manage a team of engineers and technicians in a manufacturing environment?

Effective Communication

- Establish clear communication channels and expectations.

- Provide regular updates and feedback to team members.

- Facilitate open and constructive discussions.

Delegation and Empowerment

- Delegate tasks and responsibilities based on skills and experience.

- Empower team members to make decisions and take ownership.

- Provide support and guidance when needed.

8. What is your experience with Six Sigma and how have you applied it in a manufacturing environment?

I have extensive experience with Six Sigma and have successfully applied it in various manufacturing environments to:

- Identify and eliminate defects, reducing waste and improving quality.

- Optimize processes to increase efficiency and reduce cycle times.

- Develop and implement statistical process control systems to monitor and control production processes.

- Train and certify employees in Six Sigma methodologies and tools.

- Lead cross-functional teams to address complex manufacturing challenges.

9. How would you approach reducing manufacturing costs while maintaining or improving product quality?

Process Optimization

- Analyze and streamline production processes to eliminate waste and reduce inefficiencies.

- Identify and implement cost-effective alternatives for materials and components.

- Optimize inventory management to minimize holding costs.

Supplier Management

- Negotiate favorable pricing and terms with suppliers.

- Establish long-term partnerships with reliable and cost-competitive suppliers.

- Evaluate and implement supplier performance improvement programs.

10. What are your thoughts on the future of manufacturing and how do you anticipate technology will impact the industry?

The future of manufacturing is characterized by rapid technological advancements that will significantly impact the industry:

- Automation and Robotics: Increased automation and the use of robotics will enhance productivity, accuracy, and safety.

- Digitalization: The adoption of digital technologies, such as IoT and data analytics, will enable real-time monitoring, predictive maintenance, and process optimization.

- Additive Manufacturing: 3D printing and additive manufacturing techniques will revolutionize product design and customization.

- Sustainable Manufacturing: Greater emphasis will be placed on reducing environmental impact and promoting sustainable practices.

- Reskilling and Upskilling: The workforce will need to adapt and acquire new skills to meet the demands of advanced manufacturing technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Factory Expert.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Factory Expert‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Factory Experts are highly skilled professionals responsible for optimizing manufacturing processes, ensuring product quality, and maximizing productivity within a factory environment. Their key responsibilities include:

1. Process Optimization

Analyze production processes to identify areas for improvement. Design and implement process improvements to increase efficiency, reduce costs, and enhance product quality.

2. Quality Control

Establish and maintain quality control standards for products and processes. Regularly inspect products and processes to ensure compliance with specifications.

3. Equipment Management

Manage and maintain factory equipment, including machinery, tools, and systems. Conduct preventive maintenance and repairs to prevent downtime and ensure optimal performance.

4. Production Planning

Collaborate with production and engineering teams to plan and schedule production activities. Optimize production schedules to maximize output and meet customer demand.

5. Workforce Management

Supervise and train operators and technicians. Evaluate performance and provide guidance to improve productivity and safety.

Interview Preparation Tips

To ace an interview for a Factory Expert role, candidates should focus on the following:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry. Research the latest trends and technologies in manufacturing.

- Example: Review the company website, industry publications, and LinkedIn profiles of key executives.

2. Practice Your Value Proposition

Craft a concise elevator pitch that highlights your skills, experience, and how you can add value to the company.

- Example: “As a Factory Expert with 10+ years of experience, I have successfully implemented process improvements that increased productivity by 20% and reduced waste by 15%.”

3. Prepare for Technical Questions

Study manufacturing processes, equipment maintenance, and quality control techniques. Be prepared to discuss specific examples of your experience.

- Example: Practice explaining how you implemented a lean manufacturing system or troubleshoot equipment breakdowns.

4. Demonstrate Leadership and Teamwork

Highlight your ability to lead and motivate teams, as well as collaborate effectively with other departments.

- Example: Discuss your experience in supervising a production team and implementing a safety program.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview. Express your enthusiasm for the role and the company.

- Example: Greet the interviewers warmly, make eye contact, and ask thoughtful questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Factory Expert interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!