Are you gearing up for a career in Factory Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Factory Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

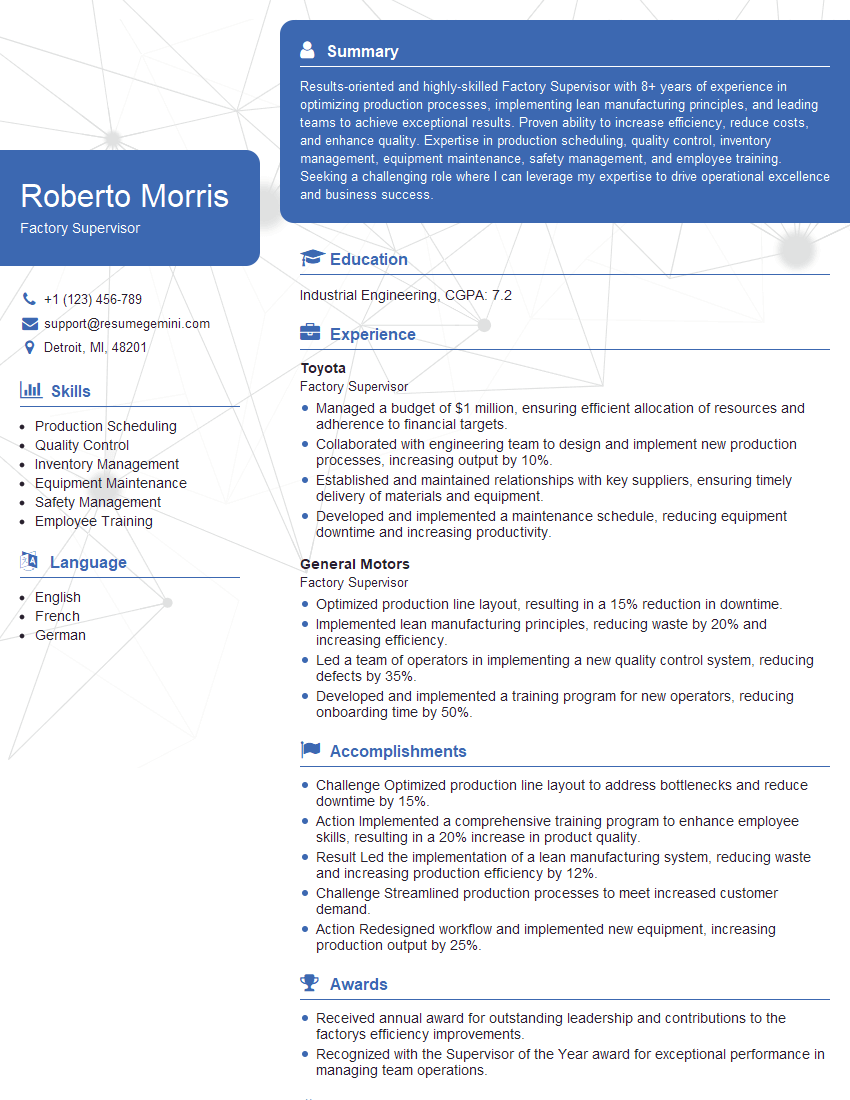

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Factory Supervisor

1. What are the key performance indicators (KPIs) you use to measure the effectiveness of your factory operations?

To measure the effectiveness of factory operations, I use a range of KPIs, including:

- Production output: This measures the number of units produced per hour, shift, or day.

- Production efficiency: This measures the ratio of actual output to standard output, indicating how efficiently the factory is operating.

- Quality control: This measures the percentage of products that meet quality standards, ensuring that products meet customer requirements.

- Machine utilization: This measures the percentage of time that machines are running and producing products, maximizing production capacity.

- Labor productivity: This measures the output per employee, indicating the efficiency of the workforce.

- Inventory levels: This measures the amount of raw materials, work-in-progress, and finished goods on hand, ensuring optimal inventory management.

2. How do you ensure that your factory meets safety and environmental regulations?

Compliance with Safety Regulations

- Conduct regular safety inspections to identify and mitigate hazards.

- Provide comprehensive safety training to employees on proper work practices and emergency procedures.

- Enforce the use of personal protective equipment (PPE) and ensure compliance with safety protocols.

- Establish and maintain a safety committee to promote employee involvement and feedback on safety concerns.

Environmental Protection

- Monitor and control emissions to comply with environmental regulations.

- Implement waste reduction programs to minimize environmental impact.

- Promote recycling and resource conservation initiatives within the factory.

- Conduct environmental audits to ensure compliance and identify areas for improvement.

3. How do you motivate and lead your team to achieve production goals?

To motivate and lead my team to achieve production goals, I implement the following strategies:

- Communicate clear goals and expectations to the team, ensuring everyone understands their roles and responsibilities.

- Provide regular feedback and recognition for accomplishments, fostering a positive and motivating work environment.

- Create opportunities for professional development and growth, empowering employees and enhancing their skills.

- Encourage teamwork and collaboration, promoting a sense of collective responsibility and shared success.

- Address challenges and obstacles promptly, providing support and guidance to the team as needed.

4. Describe a time when you had to make a difficult decision that impacted the factory’s operations. How did you approach the situation?

In a previous role, I faced a difficult decision when a critical machine malfunctioned during peak production. The situation required immediate action, as downtime would result in significant losses. I approached the situation by:

- Assessing the situation and gathering information from the maintenance team.

- Consulting with senior management to discuss options and potential consequences.

- Weighing the risks and benefits of different courses of action, considering factors such as safety, cost, and production schedules.

- Making a decision based on a thorough analysis and prioritizing the safety of employees and the long-term impact on operations.

- Communicating the decision clearly to the team and implementing the necessary actions.

5. How do you handle conflict and resolve disputes among team members?

To handle conflict and resolve disputes among team members, I employ the following strategies:

- Create a respectful and open work environment where individuals feel comfortable expressing their concerns.

- Facilitate discussions between conflicting parties, allowing them to express their perspectives and understand each other’s viewpoints.

- Identify common ground and areas of agreement, seeking solutions that address the needs of all parties involved.

- Mediate the situation, providing an objective perspective and helping the team reach a consensus.

- Document resolutions and follow up to ensure that agreements are honored and conflicts are effectively resolved.

6. How do you optimize production processes to maximize efficiency and minimize costs?

To optimize production processes and maximize efficiency while minimizing costs, I implement the following strategies:

- Conduct process mapping to identify bottlenecks and inefficiencies.

- Implement lean manufacturing principles to reduce waste and streamline operations.

- Utilize automation and technology to enhance productivity and reduce manual labor.

- Optimize inventory management to minimize holding costs and ensure just-in-time delivery.

- Regularly evaluate and update processes based on performance data and feedback.

7. How do you manage and maintain a safe and healthy work environment for your employees?

To manage and maintain a safe and healthy work environment for my employees, I implement the following measures:

- Establish and enforce safety protocols and procedures.

- Conduct regular safety inspections and risk assessments.

- Provide comprehensive safety training to employees.

- Ensure proper maintenance and inspection of equipment and machinery.

- Foster a culture of safety awareness and encourage employee participation in safety initiatives.

8. How do you ensure that your factory meets customer requirements and specifications?

To ensure that my factory meets customer requirements and specifications, I implement the following strategies:

- Establish clear and detailed specifications for all products and processes.

- Conduct regular inspections and quality checks to ensure compliance with specifications.

- Implement statistical process control techniques to monitor and improve quality.

- Obtain customer feedback and respond promptly to any concerns or issues.

- Continuously improve processes to enhance product quality and meet evolving customer demands.

9. How do you handle production delays and disruptions?

To handle production delays and disruptions, I implement the following strategies:

- Monitor production schedules closely and identify potential risks or delays.

- Develop contingency plans to mitigate the impact of disruptions.

- Communicate with customers promptly and transparently about any delays or issues.

- Work closely with the maintenance team to minimize downtime and ensure timely repairs.

- Adjust production schedules and allocate resources as needed to meet deadlines and minimize losses.

10. How do you stay up-to-date on industry best practices and technological advancements?

To stay up-to-date on industry best practices and technological advancements, I engage in the following activities:

- Attend industry conferences and seminars.

- Read trade publications and industry journals.

- Participate in online forums and professional networking groups.

- Research and evaluate new technologies that have the potential to improve factory operations.

- Collaborate with other industry professionals and experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Factory Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Factory Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Factory Supervisor, you will play a critical role in ensuring the smooth and efficient operation of the factory.

1. Production Management

This involves overseeing all aspects of production, including planning, scheduling, and monitoring.

- Develop and implement production plans.

- Manage inventory and ensure material availability.

2. Quality Control

You must maintain high standards of quality by inspecting products, ensuring compliance with specifications.

- Implement and maintain quality control systems.

- Monitor production processes to identify and mitigate quality issues.

3. Personnel Management

You will lead, motivate, and train a team to achieve production targets.

- Recruit, hire, and train new employees.

- Provide guidance, feedback, and support to team members.

4. Safety and Compliance

You will ensure a safe working environment and adherence to all relevant regulations.

- Develop and enforce safety protocols.

- Conduct regular safety training and inspections.

Interview Tips

Preparing for an interview for a Factory Supervisor position requires thorough preparation and research. Here are some tips to help you ace it:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and market position. Understanding the industry will also provide context for your answers.

2. Practice Your Answers to Common Interview Questions

Anticipate questions about your management style, production knowledge, and experience in quality control. Prepare concise and specific examples to illustrate your skills.

3. Be Specific and Quantify Your Accomplishments

When describing your accomplishments, use numbers and metrics to demonstrate their impact. For instance, instead of saying “I improved production efficiency,” quantify it: “I implemented lean manufacturing principles, increasing efficiency by 20%.”

4. Show Enthusiasm and Passion

Manufacturing is a demanding field, and demonstrating a genuine interest and commitment will impress the interviewer. Share examples of your involvement in industry events or initiatives.

5. Highlight Your Safety Focus

Safety is paramount in manufacturing. Emphasize your commitment to creating and maintaining a safe work environment. Describe your experience in safety protocols and risk management.

6. Prepare Questions for the Interviewer

Asking thoughtful questions shows engagement and interest. Prepare questions about the company’s future plans, industry trends, or the role’s specific responsibilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Factory Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!