Are you gearing up for an interview for a Fairing Man position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fairing Man and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

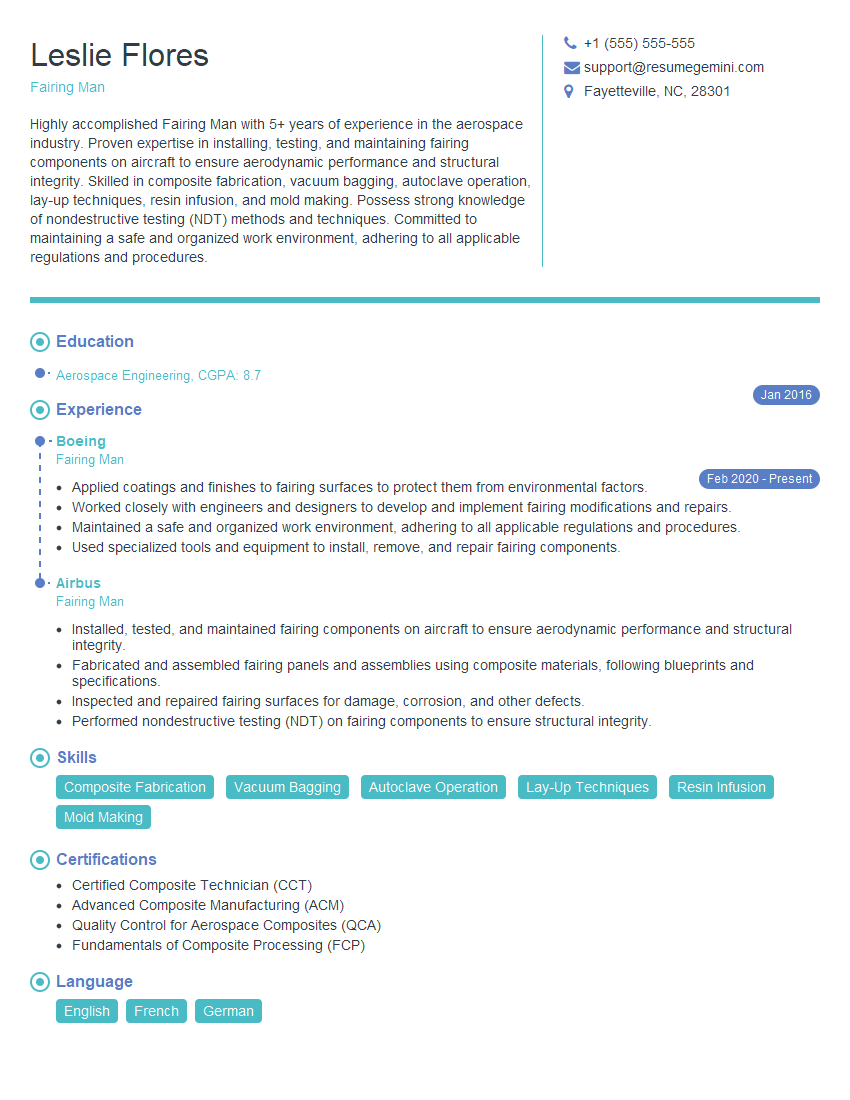

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fairing Man

1. What are the key responsibilities of a Fairing Man?

As a Fairing Man, I am responsible for the following key tasks:

- Fabricate and assemble fairing components according to engineering drawings and specifications.

- Install and align fairing components on aircraft structures using specialized tools and equipment.

- Inspect and test fairing components to ensure they meet quality and performance standards.

- Troubleshoot and repair fairing systems to maintain aircraft aerodynamic efficiency.

- Maintain a clean and organized work area, ensuring compliance with safety regulations.

2. Describe the different types of fairing materials and their properties.

Fairing materials vary based on the specific aircraft application and performance requirements. Common types include:

Composites

- Lightweight and high-strength materials often used in aerospace applications.

- Examples: carbon fiber, fiberglass, and Kevlar.

Metals

- Durable and resistant to high temperatures.

- Examples: aluminum alloys, titanium, and stainless steel.

Thermoplastics

- Lightweight and flexible materials that can be easily molded.

- Examples: polycarbonate and ABS.

3. What are the challenges of working with composite materials in fairing fabrication?

Working with composites in fairing fabrication presents several challenges:

- Handling delicate and easily damaged materials.

- Ensuring proper curing and bonding to achieve optimal performance.

- Mitigating potential health hazards associated with resin and fiber exposure.

- Maintaining strict quality control measures due to the critical nature of composite components.

4. Explain the process of installing and aligning fairing components on aircraft structures.

The installation and alignment of fairing components involve the following steps:

- Preparing the aircraft structure by cleaning and applying adhesives.

- Positioning the fairing component using jigs and fixtures for precise alignment.

- Securing the component with fasteners, such as bolts and rivets.

- Verifying alignment using measuring instruments and laser systems.

- Making any necessary adjustments to ensure proper fit and aerodynamic performance.

5. What are the common inspection and testing methods used for fairing components?

Fairing components are inspected and tested using various methods to ensure their quality and performance:

- Visual inspection for surface defects, cracks, and misalignments.

- Dimensional inspection using measuring tools and gauges.

- Non-destructive testing (NDT) techniques such as ultrasonic and radiographic testing to detect internal flaws.

- Aerodynamic testing in wind tunnels or flight tests to assess the component’s performance and impact on aircraft aerodynamics.

6. How do you troubleshoot and repair fairing systems on aircraft?

Troubleshooting and repairing fairing systems involve a systematic approach:

- Identifying the problem through visual inspection, performance analysis, or customer feedback.

- Analyzing the cause of the issue, considering factors such as damage, wear, or environmental conditions.

- Developing and implementing repair solutions, which may include patching, replacement, or modification.

- Testing and verifying the repaired component’s performance to ensure it meets specifications.

7. Describe the importance of maintaining a clean and organized work area in fairing fabrication and repair.

A clean and organized work area is crucial for several reasons:

- Ensuring the cleanliness and quality of manufactured or repaired components.

- Preventing contamination of materials and equipment.

- Reducing the risk of accidents and injuries by maintaining a safe workspace.

- Improving efficiency and productivity by minimizing distractions and maximizing accessibility.

8. How do you stay up-to-date with advancements in fairing materials and fabrication techniques?

To stay current with industry advancements, I actively engage in the following:

- Attending conferences, workshops, and training programs.

- Reading technical journals and industry publications.

- Networking with peers and experts in the field.

- Seeking opportunities to collaborate on research and development projects.

9. What are your strengths and how do they relate to the role of a Fairing Man?

My strengths include:

- Strong technical skills in composite fabrication and repair.

- Meticulous attention to detail and commitment to quality.

- Experience in using specialized tools and equipment for fairing installation and alignment.

- Proficiency in troubleshooting and resolving complex fairing issues.

- Ability to work independently and as part of a team in a fast-paced environment.

10. What are your career goals and how does this role align with them?

My career goal is to become a leading expert in fairing design, fabrication, and maintenance. This role aligns with my goals as it provides an opportunity to:

- Apply my existing skills and knowledge to contribute to the development and maintenance of critical aircraft components.

- Expand my technical expertise through hands-on experience and collaboration with experienced professionals.

- Make a significant contribution to the aerospace industry by ensuring the safety and performance of aircraft.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fairing Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fairing Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fairing Man is accountable for performing a variety of tasks related to fairing and the fabrication of components and assemblies. The individual will work under the supervision of a senior technician or engineer and will be expected to adhere to established quality standards.

1. Fairing Fabrication

The Fairing Man will be responsible for assisting in the fabrication of fairings using a variety of materials, including composites, fiberglass, and plastics.

- Cut and shape materials according to specifications.

- Bond and assemble components using adhesives, sealants, and mechanical fasteners.

2. Fairing Repair

The Fairing Man will be responsible for repairing damaged fairings.

- Inspect fairings for damage.

- Repair cracks, holes, and other damage using appropriate materials and techniques.

3. Tool and Equipment Maintenance

The Fairing Man will be responsible for maintaining tools and equipment used in fairing fabrication and repair.

- Clean and inspect tools and equipment regularly.

- Perform minor repairs on tools and equipment as needed.

4. Quality Control

The Fairing Man will be responsible for ensuring that fairings meet established quality standards.

- Inspect fairings for defects and non-conformances.

- Document and report defects and non-conformances.

Interview Tips

Preparing for an interview can be daunting, especially if you are not sure what to expect. Here are some tips to help you ace your next interview for a Fairing Man position.

1. Research the Company

2. Practice Your Answers

Take some time to practice answering common interview questions.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time.

5. Be Enthusiastic

Show the interviewer that you are excited about the opportunity to work for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fairing Man interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!