Are you gearing up for an interview for a Fairing Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fairing Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

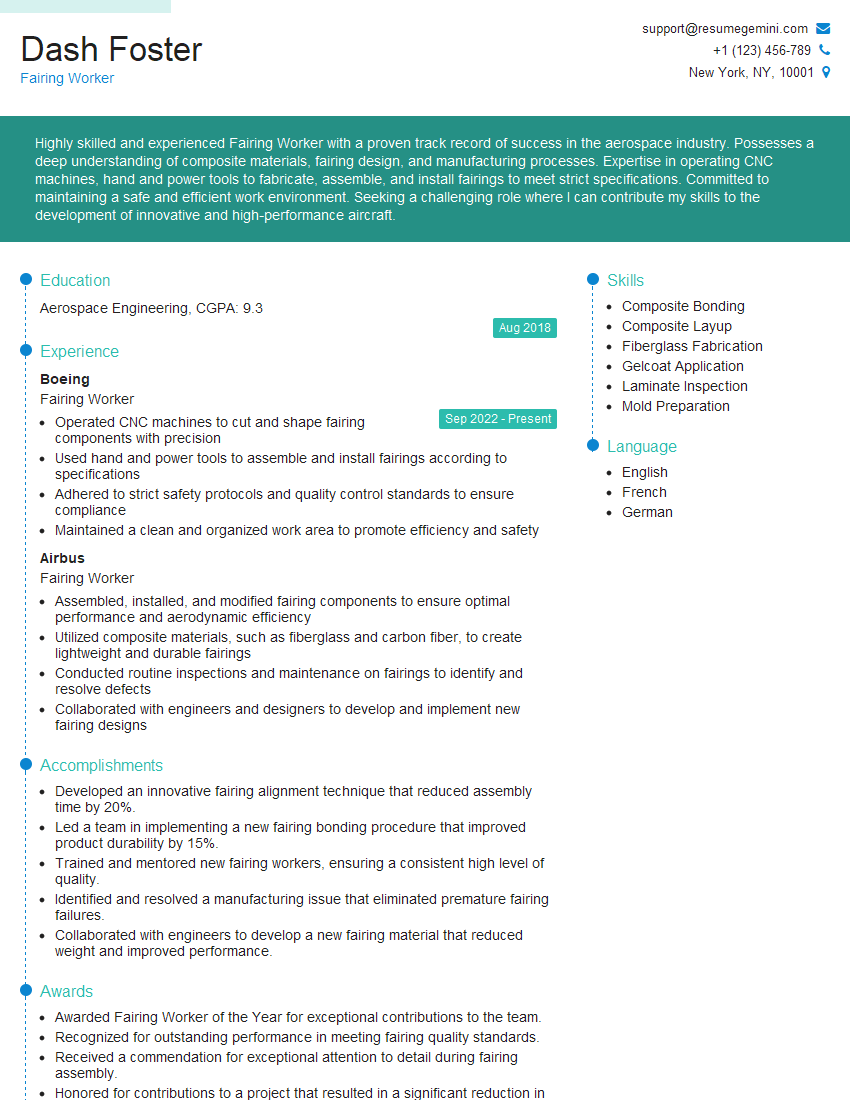

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fairing Worker

1. Describe the processes involved in fairing fabrication.

- Setup and preparation: Includes gathering materials, setting up the work area, and preparing tools.

- Layup: Fabricating the fairing by layering composite materials (e.g., fiber, resin) onto a mold or form.

- Curing: Allowing the composite materials to harden and cure at a controlled temperature and pressure.

- Trimming and finishing: Removing excess material, smoothing surfaces, and applying coatings or sealants.

- Inspection and quality control: Ensuring the fairing meets the required specifications and standards.

2. Explain the different types of composite materials used in fairing construction.

- Fiberglass: Lightweight, strong, and corrosion-resistant, suitable for light to medium-duty fairings.

- Carbon fiber: High-strength, lightweight, and stiff, used for high-performance applications.

- Kevlar: High-strength, impact-resistant, and lightweight, ideal for impact-prone areas.

- Nomex: Fire-resistant, lightweight, and strong, used in applications requiring fire protection.

- Hybrid composites: Combinations of different materials to achieve specific properties, such as strength and flexibility.

3. Discuss the safety precautions to consider when working with composite materials.

- Wear appropriate personal protective equipment (e.g., gloves, mask, eye protection).

- Handle chemicals, such as resins and solvents, with proper ventilation and use spills containment measures.

- Follow proper curing procedures to avoid exposure to hazardous fumes.

- Use sharp tools with caution and ensure they are properly maintained.

- Be aware of electrical hazards associated with power tools and equipment.

4. Describe the use of jigs and fixtures in fairing fabrication.

- Hold and position molds and forms accurately, ensuring proper alignment and shape.

- Simplify assembly processes by providing pre-drilled holes and mounting points.

- Maintain repeatability and consistency in fairing production.

- Reduce production time and improve overall efficiency.

- Ensure interchangeable parts and components.

5. Explain the importance of quality control in fairing production.

- Ensures fairings meet design specifications and customer requirements.

- Prevents defects, failures, and potential injuries or equipment damage.

- Maintains brand reputation and customer satisfaction.

- Optimizes the performance and durability of fairings.

- Reduces warranty claims and production costs.

6. Describe the challenges in working with complex fairing designs.

- Creating accurate molds and forms for intricate shapes.

- Maintaining consistent material thickness and fiber orientation.

- Ensuring proper alignment and bonding of multiple fairing components.

- Dealing with tight tolerances and dimensional requirements.

- Balancing structural integrity with weight considerations.

7. Discuss the use of 3D printing in fairing fabrication.

- Rapid prototyping and creating complex molds and forms.

- Customization of fairings for specific applications and requirements.

- Reducing fabrication time and tooling costs.

- Improving design flexibility and innovation.

- Integration with computer-aided design (CAD) for seamless design transfers.

8. Describe the maintenance and repair techniques for fairings.

- Minor damage repairs: Cleaning, filling, and painting small cracks, scratches, or dents.

- Structural repairs: Assessing damage, reinforcing affected areas, and replacing damaged components.

- Coating repair and refinishing: Removing old coatings, applying new coatings, and restoring surface finish.

- Regular inspections: Checking for signs of wear, damage, or deterioration.

- Preventive maintenance: Applying protective coatings, cleaning, and regular inspections to extend fairing lifespan.

9. Explain the importance of adhering to industry standards and specifications.

- Ensures compliance with safety and performance requirements.

- Facilitates communication and collaboration between different parties.

- Promotes consistency and reliability in fairing production.

- Helps avoid liability issues and legal complications.

- Improves product quality and customer satisfaction.

10. Discuss emerging trends and advancements in fairing technology.

- Advanced materials: Research and development of new composite materials with enhanced properties.

- Automated fabrication: Use of robotics and automation to improve efficiency and reduce production costs.

- Smart fairings: Integration of sensors and electronics for monitoring, control, and data collection.

- Sustainable practices: Focus on reducing environmental impact and using eco-friendly materials.

- Virtual and augmented reality: Applications in design, prototyping, and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fairing Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fairing Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fairing Workers are responsible for the construction and repair of fairings, which are the protective coverings that enclose aircraft fuselages and wings. The primary duties of a Fairing Worker include:

1. Material Preparation

Selecting and preparing raw materials, such as fiberglass, carbon fiber, and composite materials, for fairing fabrication.

- Inspecting materials for defects and ensuring they meet specifications.

- Cutting and shaping materials to precise dimensions using hand tools and power equipment.

2. Mold Fabrication

Creating or modifying molds to shape fairings. This involves:

- Designing and constructing mold frameworks using materials like wood, metal, and fiberglass.

- Applying release agents and gel coats to mold surfaces to ensure proper part release.

3. Lay-Up and Lamination

Layering and bonding composite materials onto molds to form fairings. The process involves:

- Applying adhesive or resin to mold surfaces.

- Layering and rolling out fiberglass, carbon fiber, or other composite materials onto the mold.

- Compacting and curing the composite layers using vacuum bagging or autoclaves.

4. Finishing and Inspection

Completing and inspecting finished fairings. This includes:

- Trimming excess materials and cleaning up the finished product.

- Inspecting fairings for defects and ensuring they meet quality standards.

- Applying surface treatments or coatings as required.

Interview Tips

1. Research the Company and Industry

Learn about the company’s history, products, and services. Research the aerospace industry, focusing on the latest trends and advancements in fairing technology.

- Visit the company’s website and social media pages.

- Read industry publications and attend webinars to gain insights.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in composite fabrication, including lay-up, lamination, and mold design. Highlight your experience with specific materials and equipment used in fairing construction.

- Quantify your accomplishments using specific metrics, such as the number of fairings produced or the cost savings achieved through process improvements.

- Prepare examples of your work or projects that demonstrate your abilities.

3. Demonstrate Attention to Detail

Fairing Workers must have a keen eye for detail and precision. Provide examples of your meticulousness and ability to meet tight tolerances.

- Describe instances where you identified and corrected errors in the fabrication process.

- Explain how you ensure the accuracy and quality of your work.

4. Showcase Problem-Solving Abilities

Fairing construction can involve unexpected challenges. Highlight your problem-solving skills and ability to adapt to changing situations.

- Share examples of how you troubleshoot and resolve production issues efficiently.

- Explain your approach to collaboration and seeking assistance when needed.

5. Prepare for Technical Questions

Be prepared to answer questions about specific aspects of fairing construction, such as:

- The different types of composite materials and their properties.

- The lay-up and lamination processes.

- The use of molds and autoclaves.

- Quality control and inspection procedures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fairing Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.