Feeling lost in a sea of interview questions? Landed that dream interview for Fastener but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fastener interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

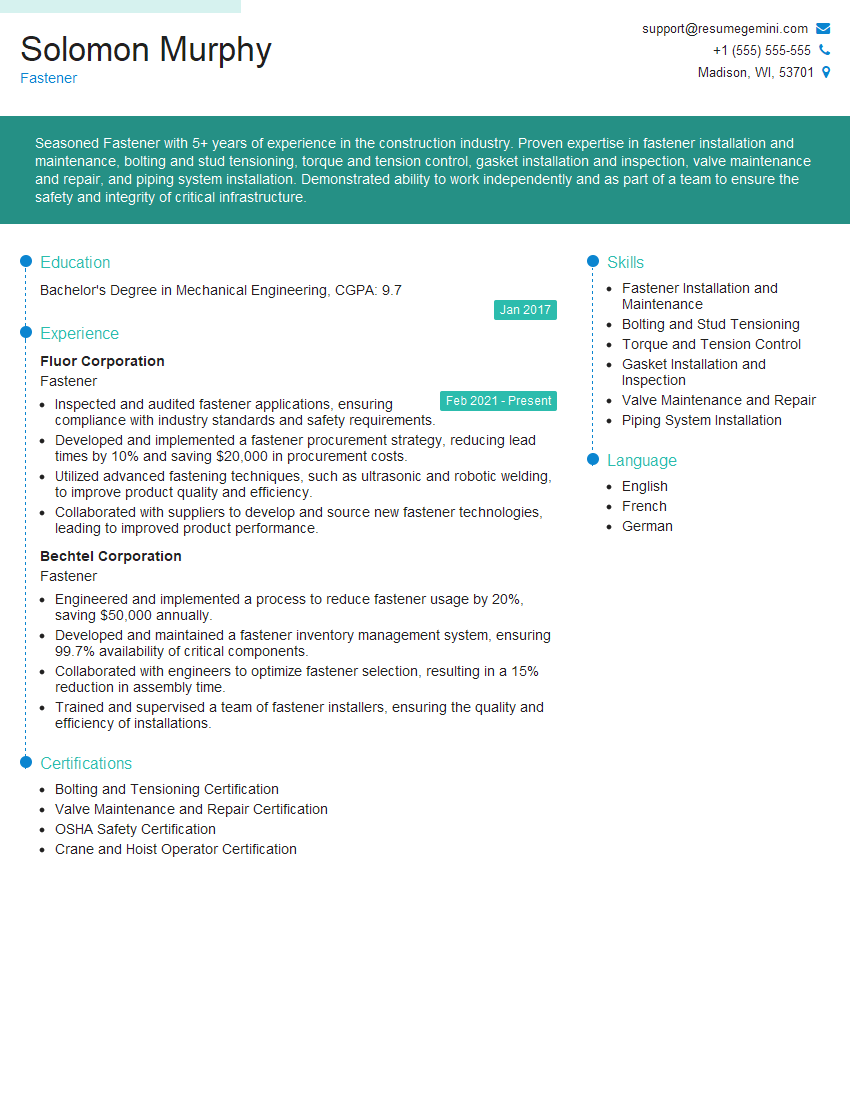

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fastener

1. What are the different types of fasteners and their applications?

There are many different types of fasteners, each with its own unique application. Some of the most common types of fasteners include:

- Bolts: Bolts are used to connect two or more pieces of material together. They are typically made of metal and have a threaded shaft that is inserted into a hole in the material. A nut is then tightened onto the bolt to secure the connection.

- Screws: Screws are similar to bolts, but they have a tapered shaft that is inserted into a pre-drilled hole. Screws are typically used to connect two pieces of material that are not as thick as the material that bolts are used for.

- Nails: Nails are used to fasten two pieces of material together by driving them through the material. Nails are typically made of metal and have a sharp point at one end. The other end of the nail is hammered into the material, creating a permanent connection.

- Rivets: Rivets are used to connect two pieces of material together permanently. They are typically made of metal and have a solid shaft that is inserted into a hole in the material. A rivet is then hammered on one end, causing the shaft to expand and create a permanent connection.

2. What are the different materials used to make fasteners?

Metals

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

Non-metals

- Plastic

- Wood

- Ceramic

- Glass

3. What are the different factors to consider when selecting a fastener?

- The type of material being fastened: The material being fastened will determine the type of fastener that is best suited for the application. For example, bolts are typically used to connect metal to metal, while screws are typically used to connect wood to wood.

- The size of the material being fastened: The size of the material being fastened will determine the size of the fastener that is needed. For example, a small bolt will be needed to connect two pieces of thin metal, while a large bolt will be needed to connect two pieces of thick metal.

- The environment in which the fastener will be used: The environment in which the fastener will be used will determine the type of material that is best suited for the application. For example, a stainless steel fastener will be needed if the fastener will be used in a corrosive environment.

4. What are the different methods of installing fasteners?

- Hand tools: Hand tools can be used to install fasteners, such as wrenches, screwdrivers, and hammers.

- Power tools: Power tools can also be used to install fasteners, such as drills, impact drivers, and nail guns.

- Automated systems: Automated systems can be used to install fasteners, such as robotic arms and assembly lines.

5. What are the different types of fastener failures?

- Tensile failure: Tensile failure occurs when the fastener is pulled apart.

- Shear failure: Shear failure occurs when the fastener is cut through.

- Fatigue failure: Fatigue failure occurs when the fastener is subjected to repeated loads.

- Corrosion failure: Corrosion failure occurs when the fastener is exposed to corrosive elements.

6. How can fastener failures be prevented?

- Using the correct type of fastener for the application

- Using the correct size of fastener for the application

- Using the correct installation method for the fastener

- Inspecting fasteners regularly for signs of wear or damage

- Replacing fasteners that show signs of wear or damage

7. What are the different types of fastener testing?

- Tensile testing: Tensile testing measures the force required to pull a fastener apart.

- Shear testing: Shear testing measures the force required to cut a fastener through.

- Fatigue testing: Fatigue testing measures the number of cycles a fastener can withstand before it fails.

- Corrosion testing: Corrosion testing measures the resistance of a fastener to corrosion.

8. What are the different standards for fasteners?

- ISO standards: ISO standards are international standards for fasteners.

- ANSI standards: ANSI standards are American National Standards for fasteners.

- ASTM standards: ASTM standards are American Society for Testing and Materials standards for fasteners.

9. What are the different certifications for fasteners?

- ISO 9001: ISO 9001 is a quality management system certification.

- ASME NQA-1: ASME NQA-1 is a quality assurance certification for nuclear power plants.

- API 6A: API 6A is a certification for oil and gas industry fasteners.

10. What are the challenges facing the fastener industry?

- Increasing global competition

- Rising raw material costs

- New environmental regulations

- Technological changes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fastener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fastener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fasteners play a crucial role in various industries, from construction to manufacturing. Key job responsibilities include:

1. Product Inspection and Quality Control

Inspecting raw materials, ensuring they meet specifications and quality standards.

- Conducting visual inspections and using measuring tools to verify dimensions, finishes, and other critical characteristics.

- Identifying and rejecting non-conforming products to prevent defects and maintain quality.

2. Manufacturing and Production

Operating machines and equipment to produce fasteners according to specifications.

- Setting up and calibrating machines, including wire drawing, thread rolling, and heat treatment equipment.

- Monitoring production processes to ensure efficiency and quality.

3. Inventory Management and Warehousing

Maintaining inventory levels, organizing and storing fasteners effectively.

- Tracking inventory using inventory management systems.

- Receiving, storing, and issuing fasteners based on customer orders.

4. Equipment Maintenance and Repair

Performing basic maintenance and repairs on machinery and equipment.

- Lubricating, cleaning, and adjusting machines to prevent breakdowns.

- Identifying and troubleshooting minor issues, performing repairs as necessary.

Interview Tips

Preparing adequately for an interview can significantly increase your chances of success. Here are some tips to consider:

1. Research the Company and Role

Take the time to research the company, its industry, and the specific role you’re applying for. This will demonstrate your interest and eagerness to learn about the position.

- Visit the company’s website to gather information about their history, mission, and values.

- Read industry publications and news articles to stay updated on the latest trends and developments.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Practice speaking clearly and confidently, and tailor your responses to the specific role and company.

- Prepare answers to questions about your experience, skills, and why you’re interested in the role.

- Consider potential questions related to the company’s industry and the specific responsibilities of the position.

3. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview, and arrive on time to show respect for the interviewer’s schedule.

- Choose formal or business casual attire, depending on the company culture and industry norms.

- Plan your route in advance to avoid any unexpected delays or getting lost.

4. Be Yourself and Be Enthusiastic

It’s important to be authentic and demonstrate your genuine interest in the role during the interview. Let your personality shine through, and show the interviewer why you’re passionate about the industry and the position.

- Be honest about your strengths and areas for improvement.

- Ask thoughtful questions to show your engagement and curiosity about the role and company.

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer. Use this opportunity to reiterate your interest in the role and thank them for their time and consideration.

- Send a personalized thank-you email or letter within 24 hours of the interview.

- Briefly restate your key qualifications and why you’re excited about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fastener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!