Are you gearing up for an interview for a Feed Mill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Feed Mill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

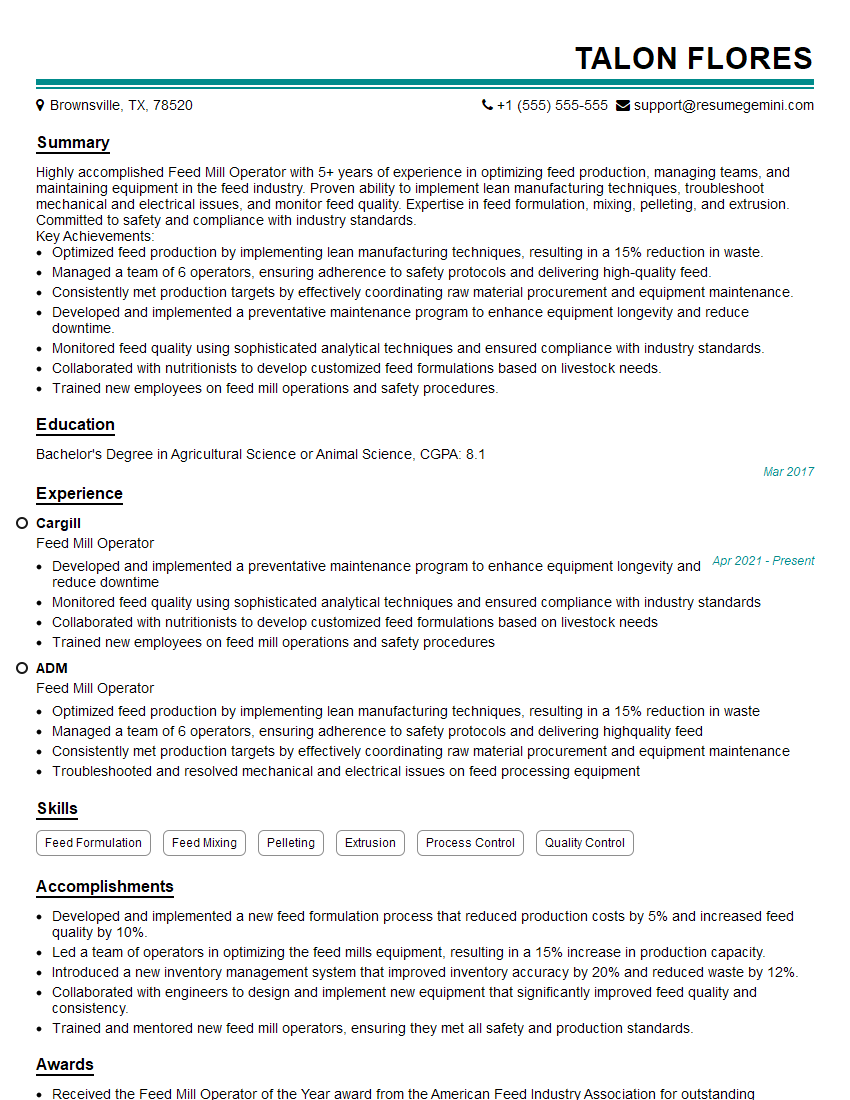

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Feed Mill Operator

1. What are the key responsibilities of a feed mill operator?

- Monitor and control the feed mill equipment to ensure optimal operation.

- Maintain and troubleshoot equipment to prevent downtime and ensure smooth production.

- Operate and adjust the feed mill equipment to meet production targets and specifications.

- Monitor and record production data and quality control parameters to ensure product quality.

- Follow established safety protocols and maintain a clean and organized work environment.

2. Describe the different types of feed mill equipment you have experience with.

Feed Grinders

- Hammer mills

- Roller mills

Feed Mixers

- Ribbon mixers

- Paddle mixers

- Auger mixers

Pellet Mills

- Flat die pelleting machines

- Ring die pelleting machines

Other Equipment

- Conveyors

- Pneumatic systems

3. How do you ensure the quality of the feed produced by the mill?

- Regularly inspect raw materials for quality and contamination.

- Monitor the grinding, mixing, and pelleting processes to ensure optimal conditions.

- Conduct periodic quality control tests on finished feed products.

- Maintain accurate records of production data and quality control parameters.

- Follow established quality assurance protocols and procedures.

4. What are the common safety hazards associated with feed mill operations, and how do you mitigate them?

- Rotating equipment: Proper guarding and lockout/tagout procedures

- Electrical hazards: Safe wiring, grounding, and regular inspections

- Dust and noise: Proper ventilation, dust masks, and hearing protection

- Chemical hazards: Handling and storage of chemicals according to MSDS guidelines

- Fire hazards: Proper ventilation, fire detection systems, and firefighting equipment

5. How do you troubleshoot and resolve equipment malfunctions in the feed mill?

- Identify the malfunctioning equipment and the symptoms.

- Refer to maintenance manuals and consult with experienced technicians.

- Check electrical connections, fuses, and switches.

- Inspect mechanical components for wear and tear.

- Troubleshoot software or control systems if applicable.

- Repair or replace faulty components as necessary.

6. How do you prioritize maintenance tasks and ensure efficient operation of the feed mill?

- Develop a preventive maintenance schedule based on equipment history and manufacturer recommendations.

- Inspect equipment regularly and identify potential issues.

- Prioritize maintenance tasks based on their urgency and impact on production.

- Schedule and complete maintenance tasks in a timely manner.

- Maintain accurate records of maintenance activities.

7. How do you handle production emergencies, such as equipment breakdowns or power outages?

- Assess the situation and identify the cause of the emergency.

- Notify supervisors and other relevant personnel.

- Shut down or isolate the affected equipment to prevent further damage.

- Implement contingency plans to minimize production losses.

- Coordinate with maintenance personnel to resolve the issue as quickly as possible.

8. How do you ensure a clean and organized work environment in the feed mill?

- Regularly clean and disinfect equipment, surfaces, and work areas.

- Remove dust, debris, and spilled materials promptly.

- Maintain proper ventilation and exhaust systems.

- Label and store chemicals and hazardous materials properly.

- Encourage good hygiene practices among employees.

9. How do you improve feed mill efficiency and optimize production?

- Analyze production data to identify areas for improvement.

- Implement lean manufacturing principles to reduce waste and improve efficiency.

- Utilize technology, such as automation and data analytics, to enhance operations.

- Train and motivate employees to improve their skills and productivity.

- Seek feedback from customers and industry experts to identify opportunities for improvement.

10. What are your goals for this role, and how do you plan to achieve them?

- Enhance feed mill efficiency and optimize production.

- Implement preventive maintenance practices to minimize equipment downtime.

- Maintain a clean and organized work environment to ensure product quality and safety.

- Develop my technical skills and knowledge in feed mill operations.

- Contribute to the overall success and growth of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Feed Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Feed Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Feeding and Monitoring Feed Mill

Feed Mill Operators are responsible for ensuring the smooth operation of the feed mill. This includes:

- Loading and unloading raw materials.

- Monitoring the feed mill’s equipment to ensure that it is running properly.

- Adjusting the feed mill’s settings to ensure that the feed is being produced according to specifications.

2. Maintaining Feed Mill Equipment

Feed Mill Operators are also responsible for maintaining the feed mill’s equipment. This includes:

- Cleaning and lubricating the feed mill’s equipment.

- Inspecting the feed mill’s equipment for wear and tear.

- Repairing the feed mill’s equipment as needed.

3. Ensuring Feed Mill Safety

Feed Mill Operators are responsible for ensuring the safety of the feed mill. This includes:

- Following all safety procedures.

- Wearing appropriate safety gear.

- Keeping the feed mill clean and organized.

4. Communication and Record Keeping

Feed Mill Operators are also responsible for communicating with other employees and keeping records. This includes:

- Reporting any problems or concerns to a supervisor.

- Keeping a log of the feed mill’s operations.

- Completing any other paperwork that is required.

Interview Tips

1. Research the Company

Before you go on an interview, it is important to research the company. This will help you to understand the company’s culture, values, and goals. You can research the company online, or you can contact the company directly for more information.

2. Practice Your Answers

Once you have researched the company, you should practice your answers to the most common interview questions. This will help you to feel more confident and prepared during your interview.

3. Dress Professionally

It is important to dress professionally for your interview. This will show the interviewer that you are serious about the job and that you are ready to work.

4. Be Yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

5. Follow Up

After your interview, it is important to follow up with the interviewer. This shows the interviewer that you are still interested in the job and that you are eager to learn more about the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Feed Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.