Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Felt Checker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

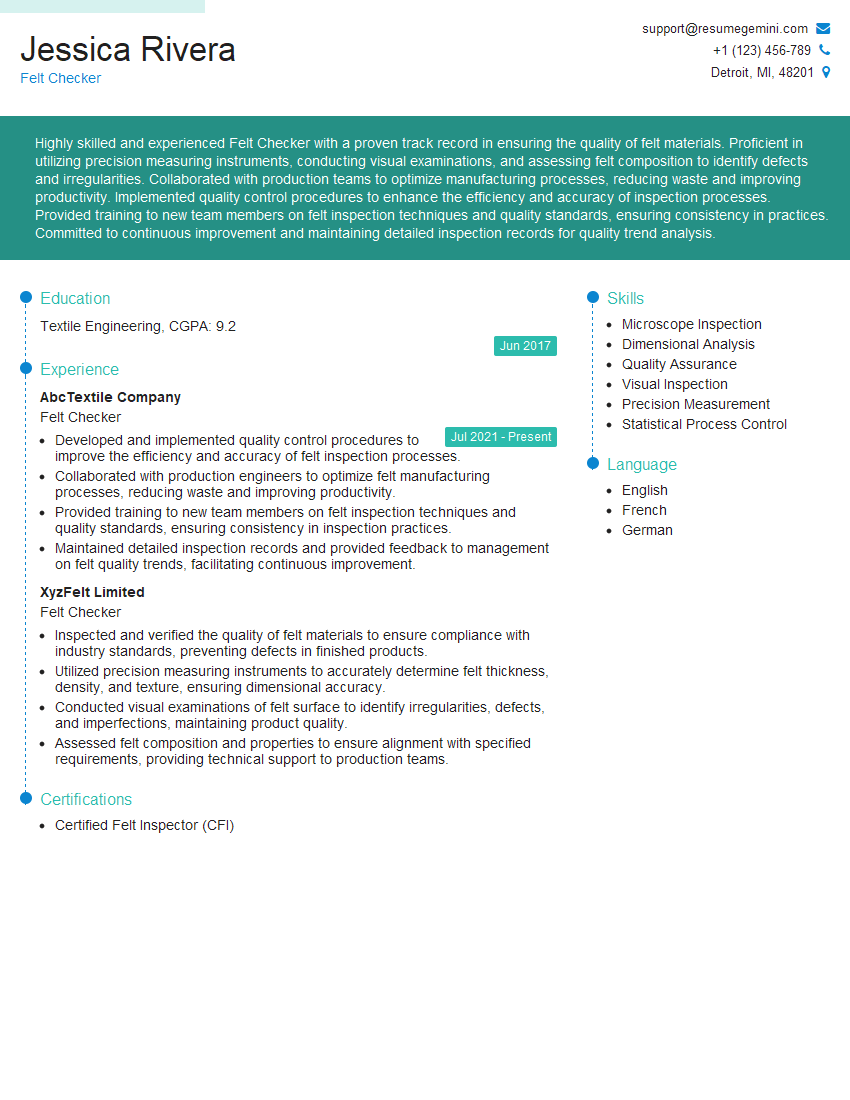

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Felt Checker

1. Describe the types of felt and their uses in different industries?

There are several types of felt, each with its properties and applications in various industries:

- Wool Felt: Made from natural wool fibers, it’s soft, durable, and flame-resistant, used in clothing, hats, and insulation.

- Synthetic Felt: Made from synthetic fibers like polyester or nylon, it’s moisture-resistant, durable, and used in filters, gaskets, and automotive parts.

- Needle-Punched Felt: Created by punching fibers together, it’s dense, stiff, and used in upholstery, flooring, and soundproofing.

- Scrim-Reinforced Felt: Made by reinforcing felt with a scrim or mesh backing, it’s used in packaging, gaskets, and sealing applications.

2. What are the key factors to consider when selecting felt for specific applications?

Material Properties

- Fiber type, thickness

- Density, stiffness

- Flame resistance

Product Requirements

- End use, performance requirements

- Environmental conditions, temperature

- Cost and availability

3. Explain the process of felt production, from raw materials to finished products?

- Raw Material: Wool or synthetic fibers are carding to align them.

- Felting: Fibers are heated and agitated with water to tangle and create a nonwoven fabric.

- Pressing and Drying: The felt is pressed to remove moisture and shape it.

- Finishing: The felt may undergo additional processes like dyeing, coating, or laminating to enhance its properties.

4. Describe the different methods used to evaluate the quality of felt?

- Thickness Measurement: Determines the thickness of the felt using calipers or gauges.

- Density Test: Measures the weight and volume of the felt to determine its density.

- Tensile Strength Test: Assesses the resistance of the felt to stretching and tearing.

- Flame Resistance Test: Evaluates the resistance of the felt to fire using standard test methods.

5. Explain the role of felt in noise control and acoustic applications?

- Sound Absorption: Felt has high sound absorption properties, reducing noise levels by absorbing sound waves.

- Vibration Damping: Felt can reduce vibrations by absorbing and dissipating energy.

- Acoustic Insulation: Felt can be used as an insulator to minimize noise transmission between rooms or buildings.

6. Describe the maintenance and storage requirements for felt products?

- Cleaning: Vacuum or dry clean to remove dust and debris.

- Avoid Moisture: Keep felt dry to prevent mold or mildew growth.

- Storage: Store in a cool, dry place away from direct sunlight.

7. Discuss the sustainability of felt as a material?

Felt has several sustainable attributes:

- Natural Fibers: Wool felt is biodegradable and recyclable.

- Longevity: Felt products can last for several years if properly maintained.

- Waste Reduction: Felt can be made from recycled materials, reducing waste in manufacturing.

8. Describe the latest innovations and trends in the felt industry?

- Acoustic Felt: Improved performance for noise control and sound absorption.

- Sustainable Felt: Use of recycled materials and eco-friendly production practices.

- Nanotechnology in Felt: Enhancement of properties like flame resistance and water repellency.

9. Discuss the challenges faced in the production and application of felt?

- Consistency: Maintaining consistent quality in felt production.

- Cost: Cost fluctuations in raw materials and production can impact pricing.

- Competition: Facing competition from other materials and substitutes.

10. Explain your understanding of the role of a Felt Checker in quality control?

- Inspecting Felt: Visually examine felt materials for defects, thickness, and quality.

- Testing Properties: Conduct tests to assess felt properties like density, tensile strength, and flame resistance.

- Reporting Defects: Document and report any defects or non-conformance to quality standards.

- Ensuring Compliance: Verify that felt products meet customer specifications and industry regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Felt Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Felt Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Felt Checker is responsible for ensuring the quality of felt products by inspecting and testing their physical properties. They also provide support to the production team and work with quality control to maintain product standards.

1. Inspect and test felt products

The Felt Checker is responsible for inspecting and testing felt products to ensure they meet the required standards. This involves visually inspecting the products for any defects, such as tears, holes, or discoloration. They also perform physical tests to measure the product’s thickness, weight, and density.

- Visually inspect felt products for defects

- Perform physical tests to measure product thickness, weight, and density

- Compare test results to product specifications

2. Provide support to the production team

The Felt Checker works closely with the production team to ensure that felt products are produced to the required standards. They provide feedback to the production team on product quality and identify any areas for improvement. They also work with the production team to develop and implement quality control procedures.

- Provide feedback to the production team on product quality

- Identify areas for improvement in the production process

- Develop and implement quality control procedures

3. Work with quality control

The Felt Checker works closely with quality control to maintain product standards. They provide quality control with data on product quality and work with them to develop and implement quality control procedures. They also participate in quality control audits and inspections.

- Provide quality control with data on product quality

- Develop and implement quality control procedures

- Participate in quality control audits and inspections

4. Other duties

The Felt Checker may also be responsible for other duties, such as:

- Maintaining records of product inspections and tests

- Training new employees on product quality standards

- Representing the company at trade shows and other events

Interview Tips

Preparing for a Felt Checker interview can be daunting, but with the right strategies, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position. This will help you understand the company’s culture, values, and what they are looking for in a Felt Checker. You can find this information on the company’s website, social media pages, and job postings.

- Visit the company’s website to learn about their history, mission, and values.

- Read job postings and descriptions carefully to understand the specific requirements of the position.

- Check out the company’s social media pages to get a sense of their culture and values.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare a brief introduction of yourself, including your experience and skills.

- Brainstorm reasons why you are interested in the position and the company.

- Practice answering questions about your experience and qualifications.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive at the interview location at least 10 minutes early.

4. Be yourself and be confident

It is important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and in your potential to be a valuable asset to the company.

- Be honest and genuine in your answers.

- Maintain eye contact and speak clearly and confidently.

- Ask questions at the end of the interview to show that you are interested and engaged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Felt Checker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.