Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Felt Cutting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Felt Cutting Machine Operator so you can tailor your answers to impress potential employers.

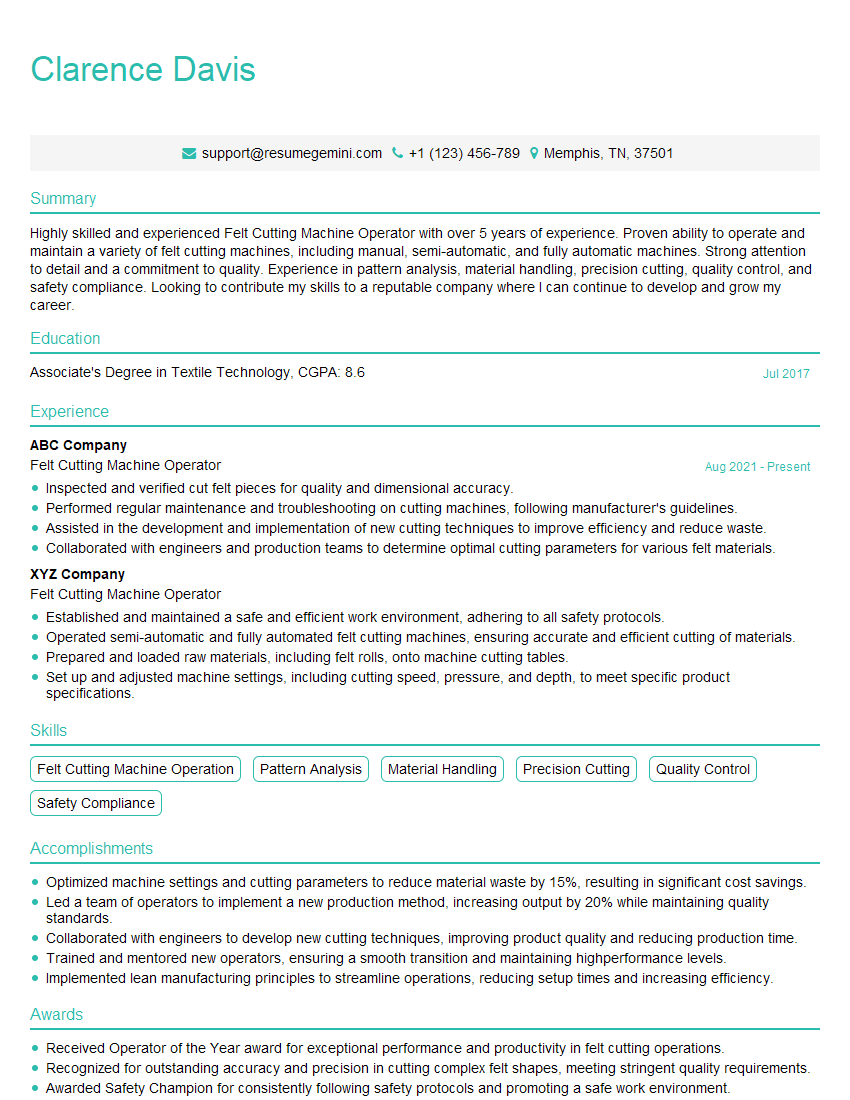

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Felt Cutting Machine Operator

1. Explain the process of setting up a felt cutting machine for a specific product?

- Initially, I would refer to the production order and material specifications to determine the required cutting parameters.

- Next, I would select the appropriate cutting blade and set it up on the machine, ensuring it is sharp and securely fastened.

- I would then load the felt material onto the cutting table, aligning it precisely according to the specified dimensions.

- Subsequently, I would program the cutting pattern into the machine’s control panel, inputting the desired cutting speed, depth, and pressure settings.

- Finally, I would conduct a test cut to verify the accuracy and quality of the setup before commencing full-scale production.

2. What are the different types of felt materials and their respective applications?

Types of Felt Materials

- Natural Wool Felt: Made from 100% sheep wool, known for its softness, durability, and insulating properties. Used in applications such as furniture padding, acoustic panels, and filters.

- Synthetic Felt: Created from man-made fibers like polyester or nylon, offering high strength, resistance to fading, and moisture. Commonly used in manufacturing clothing, hats, and industrial applications.

- Blended Felt: A combination of natural and synthetic fibers, providing a balance between the qualities of both. Used in a wide range of products, including carpets, upholstery, and craft items.

Applications

- Furniture: Padding, upholstery, and decorative elements.

- Automotive: Insulation, soundproofing, and sealing.

- Industrial: Filtration, polishing, and vibration damping.

- Fashion: Clothing, hats, and accessories.

- Home Goods: Carpets, curtains, and decorative items.

3. Describe the routine maintenance procedures required for a felt cutting machine?

- Daily Maintenance:

- Clean the cutting table and remove any debris or felt scraps.

- Inspect the cutting blade for sharpness and damage, replacing it if necessary.

- Lubricate moving parts to ensure smooth operation.

- Weekly Maintenance:

- Thoroughly clean the machine, including the control panel and other components.

- Check and adjust the cutting pressure and speed settings as needed.

- Calibrate the machine to ensure cutting accuracy.

- Monthly Maintenance:

- Inspect the electrical connections and wiring for any damage or loose connections.

- Clean and inspect the air filter and replace it if necessary.

- Perform a comprehensive performance evaluation of the machine.

4. How do you troubleshoot common problems that may arise while operating a felt cutting machine?

- Uneven Cutting:

- Check blade sharpness and replace if dull.

- Adjust cutting pressure and speed settings.

- Ensure felt material is properly aligned and secured.

- Burnt or Scorched Edges:

- Slow down cutting speed or reduce cutting pressure.

- Check blade temperature and allow it to cool if necessary.

- Ensure adequate lubrication of moving parts.

- Machine Malfunction:

- Check electrical connections and power supply.

- Reset the machine or restart the control system.

- Consult the manufacturer’s manual for specific troubleshooting steps.

5. Explain the safety precautions that must be taken when operating a felt cutting machine?

- Wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and hearing protection.

- Ensure the machine is properly grounded and electrical connections are secure.

- Keep hands and loose clothing away from moving parts.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions and safety protocols.

- Report any accidents or malfunctions to your supervisor immediately.

6. Describe your experience in optimizing cutting parameters to achieve high-quality cuts?

- In my previous role, I analyzed felt material properties and experimented with different cutting parameters.

- I determined the optimal combination of cutting speed, pressure, and blade sharpness for various felt types.

- By optimizing these parameters, I consistently achieved precise and clean cuts, minimizing waste and improving production efficiency.

7. How do you ensure the accuracy and consistency of cuts when operating a felt cutting machine?

- I meticulously calibrate the machine to maintain precise cutting dimensions.

- I regularly inspect and sharpen the cutting blade to prevent deviations in cut quality.

- I utilize templates or guides to ensure material alignment and consistent cutting patterns.

- I thoroughly check the cut pieces against specifications to guarantee accuracy.

8. Describe your experience in maintaining a clean and organized work area when operating a felt cutting machine?

- I maintain a clean work area by regularly clearing away felt scraps and debris.

- I thoroughly clean the machine and its components daily to prevent dust and fiber buildup.

- I keep tools and materials organized and easily accessible to minimize clutter.

- I adhere to established housekeeping protocols to ensure a safe and efficient work environment.

9. What is your approach to minimizing waste and maximizing material utilization when operating a felt cutting machine?

- I carefully plan cutting patterns to minimize material waste by nesting shapes efficiently.

- I utilize scrap felt for smaller projects or as padding material.

- I maintain sharp cutting blades to prevent ragged edges and minimize the need for re-cuts.

- I regularly calibrate the machine to ensure accurate cutting dimensions, reducing the likelihood of errors.

10. Explain your understanding of the importance of following manufacturer’s instructions and safety protocols when operating a felt cutting machine?

- Manufacturer’s instructions provide essential guidelines for safe and efficient operation.

- Adhering to safety protocols protects both the operator and the machine from potential hazards.

- Following established procedures ensures optimal performance and extends the machine’s lifespan.

- Ignoring instructions and protocols can compromise safety, lead to accidents, and void warranties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Felt Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Felt Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The key responsibilities of a Felt Cutting Machine Operator revolve around operating and maintaining a felt cutting machine to produce high-quality felt components. These responsibilities encompass a wide range of tasks, including:

1. Machine Operation

Operating the felt cutting machine efficiently and accurately to cut felt materials as per specified dimensions and patterns.

- Loading and unloading felt rolls onto the machine.

- Selecting and installing appropriate cutting dies.

- Adjusting machine settings, such as cutting speed and pressure.

- Monitoring the cutting process and making adjustments as needed.

2. Quality Control

Ensuring that the cut felt components meet the required quality standards.

- Inspecting cut pieces for defects, such as uneven edges or incorrect dimensions.

- Measuring and verifying the accuracy of cut pieces using measuring tools.

- Identifying and resolving any quality issues that may arise during the cutting process.

3. Machine Maintenance

Maintaining the felt cutting machine in good working condition to prevent breakdowns and ensure optimal performance.

- Cleaning and lubricating the machine as per maintenance schedules.

- Replacing worn or damaged parts as necessary.

- Performing minor repairs and adjustments to the machine.

- Reporting any major maintenance issues to the supervisor.

4. Safety Compliance

Adhering to all applicable safety regulations and guidelines while operating the felt cutting machine.

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Following established safety procedures for machine operation.

- Identifying and reporting potential safety hazards in the work area.

- Participating in safety training programs as required.

Interview Tips

To help you ace the interview for a Felt Cutting Machine Operator position, here are some tips and preparation techniques to consider:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific role you are applying for. This will demonstrate your interest in the opportunity and help you better understand the company culture and expectations.

- Visit the company’s website and social media pages to learn about their mission, values, and recent projects.

- Read industry news and articles to stay informed about the latest trends in the felt cutting industry.

2. Practice Answering Common Interview Questions

Prepare for the interview by practicing answering common questions that may be asked. This will help you build confidence and articulate your skills and experience effectively.

- Tell me about your experience operating felt cutting machines. Highlight your experience with different types of felt cutting machines, the materials you have worked with, and the quality standards you have achieved.

- How do you ensure the accuracy and quality of cut felt components? Explain your understanding of quality control procedures, your attention to detail, and your ability to identify and resolve any issues that may arise during the cutting process.

- What is your approach to maintaining and troubleshooting felt cutting machines? Demonstrate your knowledge of machine maintenance best practices, your ability to identify potential problems, and your experience in resolving common issues.

3. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company.

- What are the key challenges and opportunities facing the company in the felt cutting industry? This question demonstrates your interest in the company’s future direction and your ability to think strategically.

- What is the company’s commitment to safety and quality? This question shows that you prioritize safety and are concerned about maintaining high standards.

- What are the opportunities for professional development and career growth within the organization? This question indicates your ambition and your interest in investing in your future with the company.

4. Dress Professionally and Arrive Punctually

First impressions matter. Make sure to dress professionally and arrive for the interview on time. This shows that you respect the company and the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a manufacturing or industrial setting.

- Plan your route ahead of time to avoid any delays.

Next Step:

Now that you’re armed with the knowledge of Felt Cutting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Felt Cutting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini