Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Feltmaker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Feltmaker so you can tailor your answers to impress potential employers.

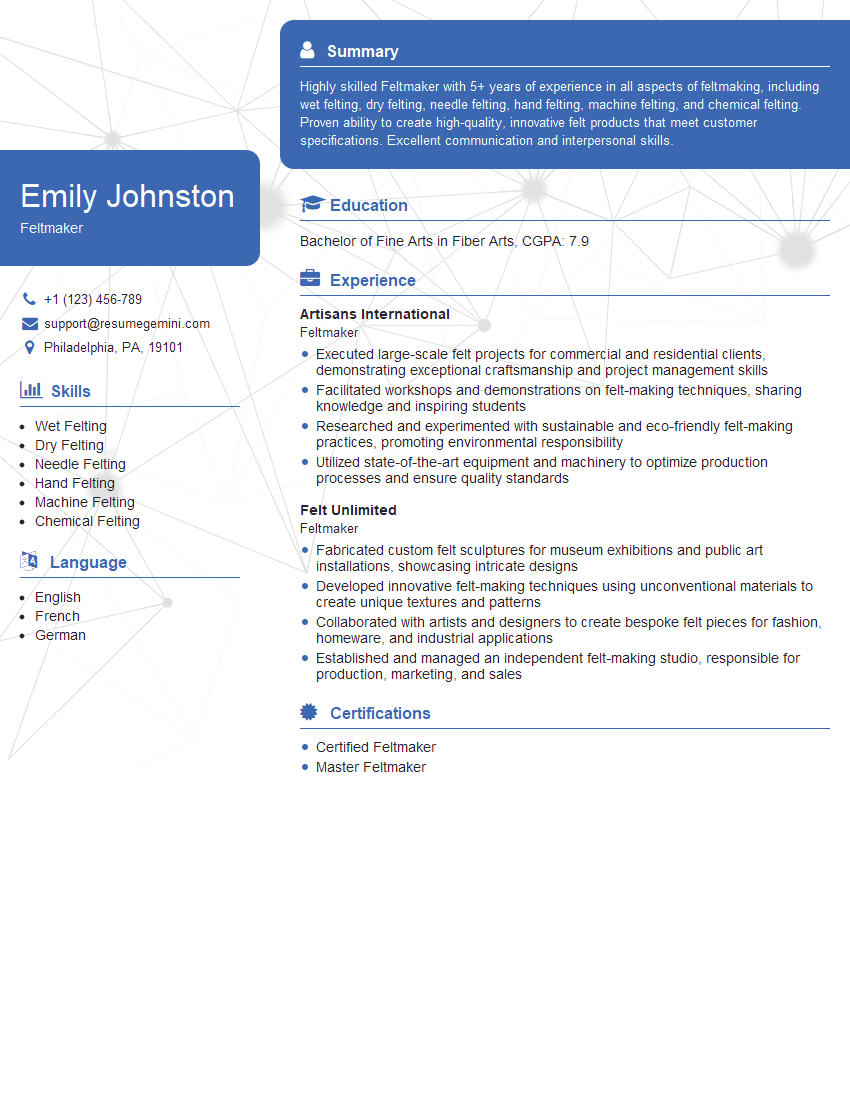

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Feltmaker

1. What are the different types of feltmaking techniques and their distinct characteristics?

Feltmaking techniques vary in terms of their approach, materials, and desired effects. Here are some common types:

- Wet Felting: Involves using water and soap to manipulate and bond wool fibers, resulting in a dense and durable felt.

- Needle Felting: Utilizes barbed needles to entangle wool fibers, creating intricate designs and three-dimensional shapes.

- Nuno Felting: Combines wool fibers with delicate fabrics like silk or lace, creating a unique and visually interesting felt.

- Shibori Felting: Incorporates traditional Japanese dyeing and folding techniques to create intricate patterns on felt.

2. Describe the key properties of wool fibers and their relevance to feltmaking.

Fiber Diameter

- Finer fibers create softer and more delicate felt.

- Coarser fibers produce more durable and abrasion-resistant felt.

Fiber Length

- Longer fibers result in stronger and more cohesive felt.

- Shorter fibers are easier to manipulate and can create a more flexible felt.

Scales

- The scales on wool fibers interlock during felting, creating the interlocking structure of the material.

- The density and arrangement of these scales determine the felt’s strength, durability, and resistance to pilling.

3. Explain the process of wet felting, outlining the steps involved and the factors that influence the final product.

Wet felting involves immersing wool fibers in warm, soapy water and manipulating them to create a bonded fabric. The process involves the following steps:

- Layering: Wool fibers are arranged in layers and moistened with water.

- Agitation: The layered fibers are agitated vigorously using hands, a felting needle, or a machine, which causes the fibers to interlock.

- Rolling and Pressing: The agitated fibers are rolled and pressed to increase the density and cohesion of the felt.

- Rinsing and Drying: The felted fabric is rinsed thoroughly to remove excess soap and dried to complete the process.

Factors Influencing the Final Product

- Fiber type and quality

- Water temperature and soap concentration

- Agitation intensity and duration

- Rolling and pressing techniques

4. Describe the applications of needle felting and the unique design possibilities it offers.

Needle felting involves using barbed needles to entangle wool fibers, creating a versatile and expressive craft technique. It offers a wide range of applications, including:

- Three-Dimensional Sculptures: Needle felting allows for the creation of intricate and lifelike sculptures of animals, figures, and objects.

- Surface Embellishments: Needle felting can be used to add texture, color, and designs to clothing, accessories, and home décor.

- Jewelry Making: Needle felted beads, pendants, and earrings can be created with intricate details and unique patterns.

- Mixed Media: Needle felting can be combined with other art forms, such as painting, embroidery, and collage, to create one-of-a-kind pieces.

5. Explain the role of dyes and pigments in feltmaking and discuss the different methods of incorporating color into felt.

Dyes and pigments play a crucial role in adding color and design to felt. Various methods can be used to incorporate color:

- Fiber Dyeing: Wool fibers can be dyed before felting to create vibrant and consistent colors.

- Bath Dyeing: Felt can be immersed in a dye bath after felting to achieve solid colors or gradient effects.

- Surface Painting: Felt can be painted or brushed with dyes or pigments after felting, allowing for intricate designs and patterns.

- Inclusion Dyeing: Colored fibers or fabrics can be incorporated into the felt during the felting process.

6. Describe the techniques used to create texture and patterns in felt and explain how they can enhance the visual appeal of the final product.

Creating texture and patterns in felt involves manipulating the fibers during the felting process:

- Layering: Layering different colored or textured fibers creates depth and visual interest.

- Rolling and Pressing: Applying pressure to the felt while rolling or pressing can create ridges, folds, and other textures.

- Needle Felting: Using barbed needles to entangle fibers allows for precise control of texture and detail.

- Embellishments: Beads, sequins, or other materials can be added to the felt surface to create additional texture and patterns.

7. Discuss the different finishing techniques used in feltmaking and their effects on the final product.

Finishing techniques enhance the appearance and durability of felt:

- Fulling: Mechanical agitation or pounding of the felt helps to compact and strengthen the fibers.

- Blocking: Shaping the felt while wet and allowing it to dry in that shape sets the desired form.

- Steaming: Exposing the felt to steam relaxes the fibers, softens the texture, and removes wrinkles.

- Brushing: Gently brushing the felt can raise the nap and provide a soft, velvety texture.

8. Explain the importance of fiber preparation in feltmaking and describe the steps involved in preparing wool fibers for felting.

Proper fiber preparation ensures the success of the felting process:

- Carding: Loosens and aligns the fibers, removing impurities and tangles.

- Combing: Removes shorter and weaker fibers, creating a more uniform and stronger batt of wool.

- Washing: Removes dirt, grease, and lanolin, allowing the fibers to absorb water and felt more effectively.

9. Discuss the environmental considerations involved in feltmaking and explain how sustainable practices can be incorporated into the process.

Feltmaking involves using natural materials, but it’s important to consider environmental impacts:

- Wool Sourcing: Choose ethically sourced wool from sustainable farms that prioritize animal welfare.

- Dyeing and Finishing: Opt for eco-friendly dyes and finishing agents that minimize chemical pollution.

- Water Conservation: Implement water-saving practices during fiber preparation and felting to reduce water consumption.

- Waste Reduction: Reuse and recycle felt scraps to minimize waste.

10. Describe the challenges you have faced in feltmaking and how you have overcome them.

Feltmaking presents various challenges, but with patience and experimentation, they can be resolved:

- Uneven Felting: Inconsistent agitation or pressure during felting can lead to uneven shrinkage and texture. Overcome this by maintaining consistent techniques and using a felting needle for detail.

- Fiber Migration: Colors or fibers can bleed into each other during felting. Mitigate this by isolating colors with barriers or using pre-dyed fibers.

- Shrinkage Control: Excessive shrinkage can distort the desired shape. Experiment with different fiber blends and felting intensities to control shrinkage effectively.

- Cracking: Felt can crack or tear if it dries too quickly. Avoid rapid drying and gradually increase heat exposure to prevent cracking.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Feltmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Feltmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Feltmakers work independently or under the supervision of a manager or production supervisor to create felt products using various techniques.

1. Prepare and Treat Fibers

Feltmakers start by preparing and treating natural or synthetic fibers, blending them to create the desired texture, color, and thickness.

- Select and mix fibers based on desired properties, such as wool, mohair, or synthetics.

- Clean and card fibers to remove impurities and align them.

2. Form and Shape Felt

Various techniques are used to form and shape felt, including wet felting, needle felting, and machine felting:

- Wet felting: Agitate fibers in hot water and soap, causing them to entangle and form a solid fabric.

- Needle felting: Use specialized needles to puncture fibers and mat them together.

- Machine felting: Use specialized machinery to press, heat, and manipulate fibers into the desired shape.

3. Finish and Embellish Felt

Once the felt is formed, it undergoes finishing and embellishment processes:

- Trim excess fibers and refine edges.

- Add decorative elements, such as embroidery, stitching, or beads.

4. Inspect and Maintain Equipment

Feltmakers are responsible for inspecting and maintaining their equipment regularly:

- Check for proper functioning of machinery and tools.

- Clean and calibrate equipment to ensure optimal performance.

Interview Preparation Tips

To ace the interview for a feltmaker position, it’s essential to demonstrate your skills and knowledge in the following areas:

1. Technical Expertise

Highlight your proficiency in various felting techniques, including wet felting, needle felting, and machine felting.

- Quantify your experience in terms of the types and quantities of felt products you have created.

- Showcase your understanding of the properties of different fibers and their impact on the finished felt.

2. Design and Innovation

Emphasize your creative abilities and passion for feltmaking.

- Discuss your experience in developing original felt designs or improving existing ones.

- Describe your knowledge of different embellishment techniques and how you incorporate them into your work.

3. Equipment Knowledge

Demonstrate your familiarity with the equipment used in feltmaking and your ability to maintain it.

- Explain your experience in assembling, setting up, and operating felting machinery.

- Describe your understanding of troubleshooting common equipment issues.

4. Quality Control

Highlight your commitment to producing high-quality felt products.

- Explain your quality inspection process and the standards you adhere to.

- Discuss your experience in identifying and correcting defects in felt.

5. Safety and Compliance

Emphasize your understanding of safety protocols and compliance regulations within the feltmaking industry.

- Explain your knowledge of proper handling and storage of felting materials.

- Describe your experience in maintaining a clean and organized work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Feltmaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Feltmaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.