Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fender Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

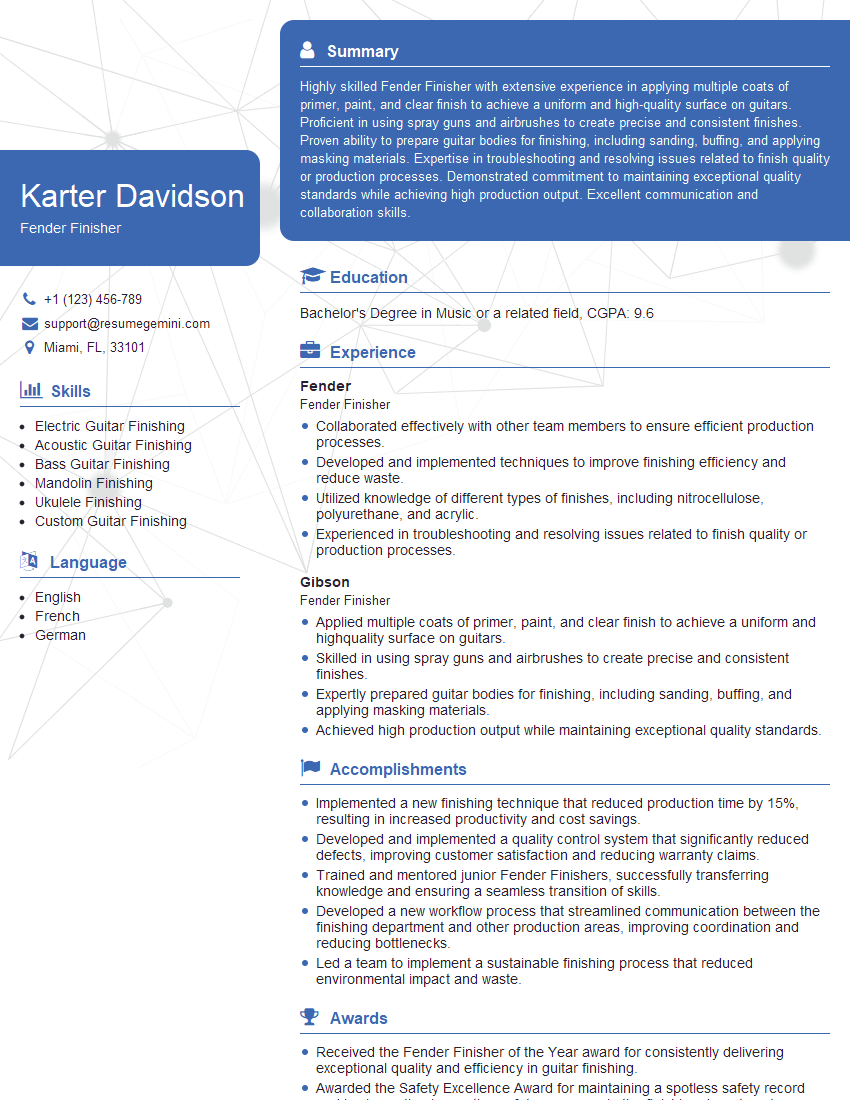

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fender Finisher

1. What is the first step involved in finishing a fender?

The first step in finishing a fender is to sand the surface to remove any imperfections or blemishes. This can be done by hand or with a power sander, and the grit of the sandpaper will depend on the condition of the fender.

2. What are the different types of finishes that can be applied to a fender?

Nitrocellulose lacquer

- Nitrocellulose lacquer is a classic finish that is often used on high-end guitars. It is a type of solvent-based finish that dries quickly and provides a durable, glossy finish.

Polyurethane

- Polyurethane is a more modern finish that is often used on electric guitars. It is a type of water-based finish that is more durable than nitrocellulose lacquer and provides a more matte finish.

Shellac

- Shellac is a natural finish that is often used on acoustic guitars. It is a type of alcohol-based finish that dries quickly and provides a warm, mellow finish.

3. What are the different techniques that can be used to apply a finish to a fender?

There are a variety of different techniques that can be used to apply a finish to a fender, including brushing, spraying, and dipping. The choice of technique will depend on the type of finish being applied and the desired results.

4. What is the difference between a wet finish and a dry finish?

- A wet finish is a finish that is applied to the fender while it is still wet. This type of finish will produce a more even and smooth finish than a dry finish.

- A dry finish is a finish that is applied to the fender after it has dried. This type of finish will produce a more textured finish than a wet finish.

5. What are the different types of equipment that are used in fender finishing?

- Sanding equipment

- Spray guns

- Brushes

- Dipping tanks

- Ovens

6. What are the safety precautions that should be taken when finishing a fender?

- Wear a respirator to protect your lungs from harmful fumes.

- Wear gloves to protect your skin from chemicals.

- Work in a well-ventilated area.

- Use caution when handling sharp tools.

7. What is the importance of quality control in fender finishing?

Quality control is important in fender finishing to ensure that the finished product meets the desired specifications. This includes checking the finish for any imperfections or defects, and making sure that the finish is applied evenly and to the correct thickness.

8. What are the different types of дефекты that can occur in fender finishing?

- Runs and sags

- Bubbles

- Orange peel

- Fish eyes

- Cracks

9. What are the causes of these дефекты?

- Runs and sags can be caused by applying the finish too thickly or by not allowing the finish to dry properly.

- Bubbles can be caused by trapped air or moisture in the finish.

- Orange peel can be caused by using the wrong type of sandpaper or by not sanding the surface properly.

- Fish eyes can be caused by contamination of the finish with oil or grease.

- Cracks can be caused by using too much pressure when sanding or by not allowing the finish to dry properly.

10. How can these дефекты be prevented?

- Runs and sags can be prevented by applying the finish in thin, even coats and by allowing the finish to dry properly.

- Bubbles can be prevented by removing all traces of air and moisture from the surface before applying the finish.

- Orange peel can be prevented by using the correct type of sandpaper and by sanding the surface properly.

- Fish eyes can be prevented by cleaning the surface thoroughly before applying the finish and by using a tack cloth to remove any dust or debris.

- Cracks can be prevented by using the correct sanding technique and by allowing the finish to dry properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fender Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fender Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fender Finishers play a crucial role in ensuring the aesthetic appeal and durability of musical instruments, primarily guitars and basses. Their responsibilities cover various aspects of the finishing process, demanding precision, attention to detail, and a keen eye for quality.

1. Surface Preparation

Preparing the instrument’s body and neck for finishing is essential. This includes sanding, smoothing, and leveling the surfaces, ensuring a flawless base for subsequent processes.

2. Staining and Coloring

Fender Finishers apply stains or dyes to achieve specific color tones and grain enhancements. They use brushes, spray guns, or other techniques to create the desired effects, contributing to the instrument’s aesthetic appeal.

3. Applying Clear Coats

Multiple layers of clear coats, such as nitrocellulose lacquer or polyurethane, are applied to protect the instrument’s finish from wear, scratches, and environmental factors. Fender Finishers must control the thickness, smoothness, and gloss level to ensure a durable and visually pleasing surface.

4. Sanding and Polishing

After applying clear coats, Fender Finishers carefully sand and polish the surfaces to achieve the desired level of smoothness and shine. They use various grits of sandpaper and polishing compounds to create a mirror-like finish that enhances the instrument’s overall appearance.

5. Aging and Relic Processes

For certain vintage-style instruments, Fender Finishers use aging and relic techniques to create the illusion of age or wear. This involves applying chemical treatments, distressing the surfaces, or adding patina to replicate the characteristics of well-played instruments.

6. Quality Control

Fender Finishers are responsible for ensuring the finished instruments meet the company’s high quality standards. They inspect the surfaces for blemishes, imperfections, or any other inconsistencies before the guitars or basses are assembled and shipped to customers.

Interview Tips

Preparing for a Fender Finisher interview requires a comprehensive understanding of the job’s responsibilities and the industry’s expectations. Here are some tips to help candidates ace their interview:

1. Research Fender and the Guitar Industry

Familiarize yourself with the history, products, and culture of Fender, the company you’re applying to. Research the broader guitar industry, including trends, innovations, and leading manufacturers. This knowledge will demonstrate your interest and enthusiasm for the field.

2. Highlight Your Skills and Experience

Emphasize your technical skills in surface preparation, staining, clear coat application, and sanding/polishing. Showcase your understanding of different finishing techniques, materials, and tools. If you have experience in aging or relic processes, highlight those skills as well.

3. Prepare Examples of Your Work

If possible, bring examples of finished instruments that showcase your craftsmanship and attention to detail. Photographs or digital portfolios are also acceptable. This will provide the interviewers with a tangible demonstration of your abilities.

4. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain eye contact and demonstrate a positive, enthusiastic attitude. Express your passion for guitars and the finishing process, and explain why you’re eager to join the Fender team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fender Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!