Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fender Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fender Mechanic so you can tailor your answers to impress potential employers.

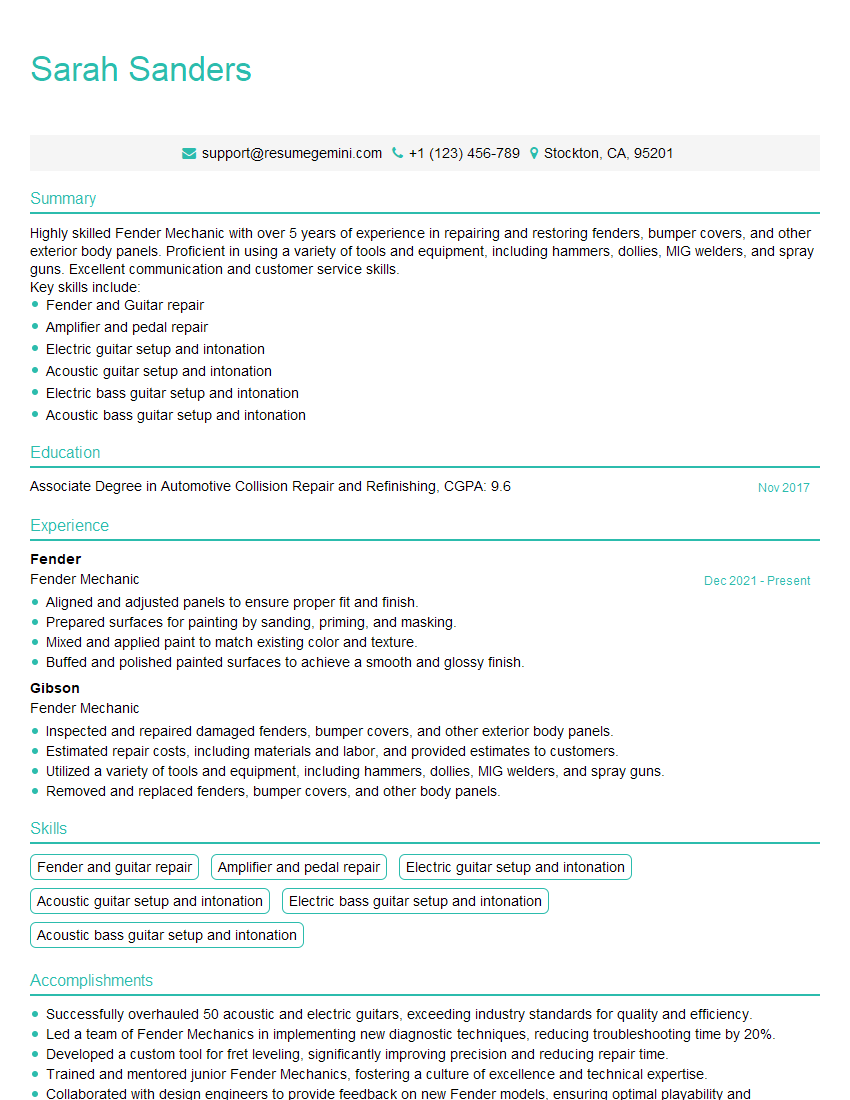

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fender Mechanic

1. Describe the steps involved in replacing a fender on a vehicle.

- Gather necessary tools and materials.

- Remove the bolts or screws holding the fender in place.

- Disconnect any electrical connectors attached to the fender.

- Carefully lift the fender off the vehicle.

- Clean the mounting surface on the vehicle.

- Apply a sealant or adhesive to the mounting surface.

- Place the new fender on the vehicle and align it properly.

- Secure the fender with bolts or screws.

- Reconnect any electrical connectors.

- Check the alignment of the fender and make any necessary adjustments.

2. How would you diagnose and repair a damaged fender?

Inspection

- Visually inspect the fender for dents, scratches, or cracks.

- Check for any underlying structural damage.

Repair

- If the damage is minor, such as a dent or scratch, it may be possible to repair it using a dent puller or body filler.

- If the damage is more severe, such as a crack or structural damage, it may be necessary to replace the fender.

3. Explain the different types of materials used in fender construction and their advantages and disadvantages.

- Steel: Strong and durable, but prone to rust.

- Aluminum: Lightweight and corrosion-resistant, but more expensive than steel.

- Plastic: Lightweight and inexpensive, but less durable than steel or aluminum.

- Fiberglass: Lightweight and durable, but can be more difficult to repair than other materials.

- Carbon fiber: Very lightweight and strong, but extremely expensive.

4. What are the safety precautions that must be taken when working on a vehicle’s fender?

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Use caution when working with sharp tools or chemicals.

- Never work on a vehicle that is supported only by a jack.

- Be aware of your surroundings and avoid tripping hazards.

- Follow all manufacturer’s instructions for the repair materials and equipment you are using.

5. How do you ensure that a repaired fender is properly aligned and fitted to the vehicle?

- Use a measuring tape or alignment tool to check the distance between the fender and other body panels.

- Check the gaps between the fender and the doors, hood, and bumper.

- Ensure that the fender is properly secured to the vehicle and that all bolts or screws are tightened to the correct torque.

- Drive the vehicle and check for any unusual noises or vibrations that may indicate an alignment issue.

6. Explain the process of painting or refinishing a fender.

- Preparation: Clean the fender thoroughly and remove any rust or debris.

- Primer: Apply a primer to the fender to help the paint adhere.

- Paint: Apply several coats of paint to the fender, allowing each coat to dry completely.

- Clear coat: Apply a clear coat to protect the paint from wear and tear.

- Polishing: Polish the fender to give it a smooth and glossy finish.

7. How do you troubleshoot and repair electrical problems related to a fender, such as malfunctioning lights or sensors?

- Use a multimeter to check for continuity in the electrical circuits.

- Inspect the wiring for any breaks or damage.

- Test the lights or sensors to determine if they are functioning properly.

- Repair or replace any faulty components.

8. Describe the different types of fender flares and their purpose.

- Stock fender flares: Designed to protect the fender from road debris.

- Aftermarket fender flares: Can be used to customize the look of a vehicle or to provide additional protection.

- Bushwacker fender flares: Made from a durable material that is resistant to UV rays and impact.

- Smittybilt fender flares: Designed for off-road use and provide maximum protection from mud and rocks.

- Dee Zee fender flares: Made from a high-quality material that is resistant to rust and corrosion.

9. How do you remove a rusted or seized bolt or screw from a fender?

- Use a penetrating lubricant to loosen the bolt or screw.

- Apply heat to the bolt or screw using a torch or heat gun.

- Tap the bolt or screw with a hammer to break it loose.

- Use a bolt extractor to remove the bolt or screw.

10. What are the common causes of fender damage?

- Collisions: Fender damage is often caused by collisions with other vehicles or objects.

- Road debris: Rocks and other road debris can hit and damage fenders.

- Rust: Rust can cause fenders to weaken and become damaged.

- Improper installation: If a fender is not installed properly, it can become loose and damaged.

- Off-road driving: Off-road driving can put stress on fenders and cause them to damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fender Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fender Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fender Mechanics are responsible for maintaining, repairing, and reconditioning fenders of motor vehicles, including cars, trucks, buses, and trailers. They work in auto body shops, dealerships, and repair centers.

1. Assessment and Inspection

Fender Mechanics assess the damage to fenders, including dents, scratches, and rust.

- Inspect fenders for damage, such as dents, scratches, cracks, and rust.

- Determine the extent of the damage and assess the necessary repairs.

2. Repair and Replacement

They repair or replace damaged fenders, using a variety of tools and techniques.

- Remove fenders from vehicles.

- Repair or replace damaged fenders using techniques such as welding, grinding, and painting.

3. Painting and Finishing

Fender Mechanics paint and finish fenders to match the rest of the vehicle.

- Prepare fenders for painting by sanding, priming, and masking.

- Apply paint to fenders, using spray guns or brushes.

4. Quality Control

They ensure that repaired fenders meet quality standards and are safe for use.

- Inspect repaired fenders to ensure they meet quality standards.

- Test repaired fenders to ensure they are safe for use.

Interview Tips

Preparing for a Fender Mechanic interview can help you stand out from other candidates. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you’re applying for. This will help you better understand the company’s culture and what they’re looking for in a Fender Mechanic.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get an idea of what it’s like to work there.

- Check out the job description for the position you’re applying for, and make sure you have the qualifications they’re looking for.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Fender Mechanic interviews. By practicing your answers to these questions, you can increase your confidence and deliver more polished responses.

- “Tell me about your experience as a Fender Mechanic.” – In your answer, highlight your skills and experience in repairing and replacing fenders. Be sure to mention any specific techniques or equipment that you’re proficient in.

- “Why are you interested in working for our company?” – In your answer, express your interest in the company’s culture and values. Explain why you think you would be a good fit for the position, and how your skills and experience would benefit the company.

3. Bring a Portfolio of Your Work

If you have a portfolio of your work, it can be helpful to bring it to your interview. This will give the interviewer a chance to see firsthand the quality of your work, and it can help you stand out from other candidates.

- Your portfolio should include a variety of your work, including examples of fender repairs, replacements, and painting.

- Make sure your portfolio is well-organized and easy to navigate.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you’re respectful of their time, and it will make a good impression.

- Dress in business casual attire, such as a button-down shirt and slacks.

- Make sure your clothes are clean and pressed.

- Arrive for your interview a few minutes early, so you have time to relax and collect your thoughts.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fender Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.