Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fermentation Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

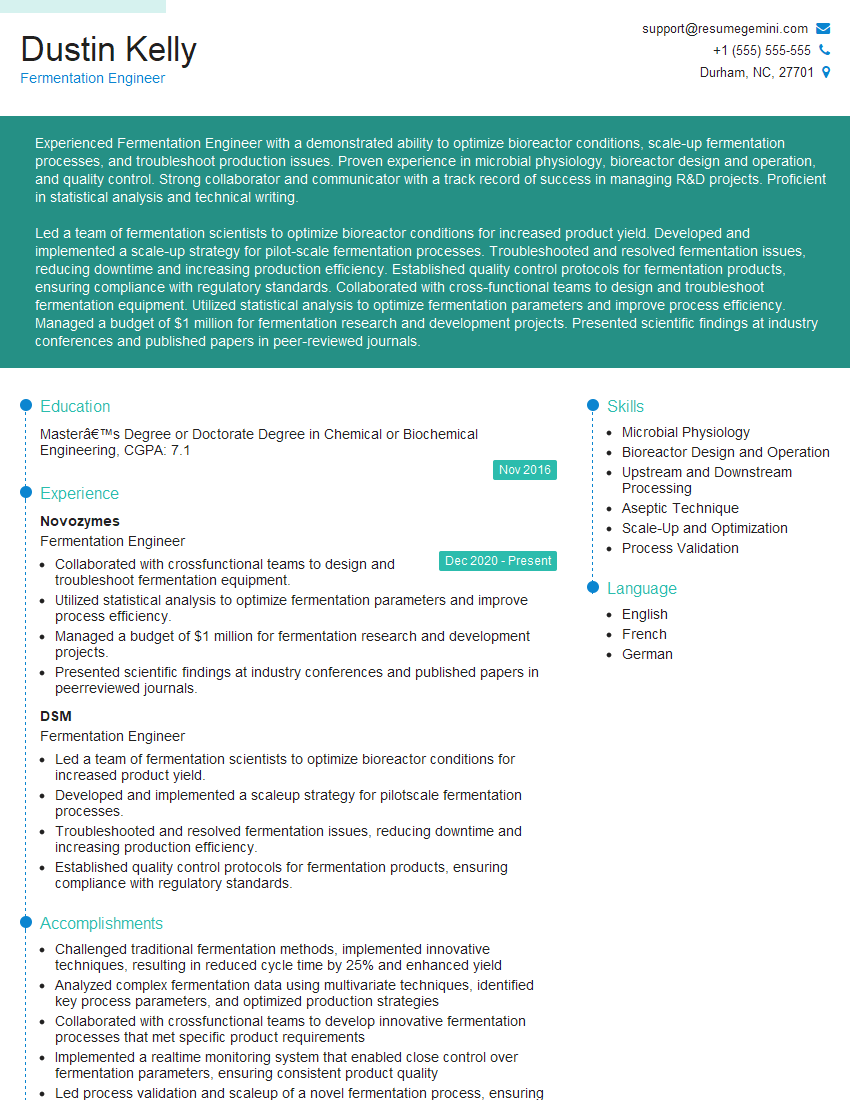

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermentation Engineer

1. Describe the key unit operations involved in a typical fermentation process?

- Bioreactor design and operation

- Media preparation and sterilization

- Inoculum preparation and scale-up

- Fermentation monitoring and control

- Product recovery and purification

2. Explain the different types of bioreactors used in industrial fermentation?

Stirred-tank bioreactors

- Advantages: High mass and heat transfer rates, good mixing

- Disadvantages: Shear forces can damage cells, limited oxygen transfer at high cell densities

Airlift bioreactors

- Advantages: Low shear forces, high oxygen transfer rates

- Disadvantages: Lower mass transfer rates compared to stirred-tank bioreactors

Packed-bed bioreactors

- Advantages: High cell densities, good mass transfer rates

- Disadvantages: Clogging issues, limited oxygen transfer

3. How do you optimize fermentation conditions for a specific product?

- Identify critical process parameters (e.g., temperature, pH, dissolved oxygen)

- Design experiments to determine optimal conditions

- Use statistical techniques to analyze data and identify trends

- Scale-up fermentation process based on optimized conditions

4. Describe the role of microorganisms in fermentation processes?

- Microorganisms convert substrates into desired products through metabolic pathways

- Selection of appropriate microorganisms is crucial for efficient fermentation

- Strain improvement techniques can enhance product yield and quality

5. What are the challenges in scaling up fermentation processes from lab to industrial scale?

- Maintaining sterility and preventing contamination

- Ensuring adequate mass and heat transfer in large-scale bioreactors

- Controlling process parameters precisely to achieve desired product quality

- Optimizing media composition and feeding strategies

6. How do you troubleshoot common problems encountered in fermentation processes?

- Low product yield: Check substrate availability, microbial viability, process conditions

- Contamination: Implement strict sterility measures, identify and eliminate contamination source

- Foam formation: Adjust media composition, use anti-foaming agents

- Equipment failure: Conduct regular maintenance, have backup systems in place

7. What are the emerging trends in fermentation technology?

- Continuous fermentation processes

- Use of alternative feedstocks (e.g., biomass, waste materials)

- Integration of fermentation with downstream processing

- Automation and process control

8. How do you ensure the safety and regulatory compliance of fermentation processes?

- Adhere to Good Manufacturing Practices (GMPs)

- Conduct risk assessments and implement safety protocols

- Comply with regulatory requirements for product quality and environmental protection

- Monitor process parameters and maintain detailed records

9. What are your strengths and weaknesses as a Fermentation Engineer?

- Strong understanding of fermentation principles and unit operations

- Experience in designing, optimizing, and troubleshooting fermentation processes

- Proficient in bioreactor operation and control

- Excellent communication and teamwork skills

- Limited experience in large-scale fermentation

- Need to develop a deeper understanding of downstream processing

Strengths

Weaknesses

10. If hired, what contributions can you make to our team?

- Use my skills to optimize existing fermentation processes and improve product yield

- Develop innovative fermentation strategies to meet emerging market demands

- Collaborate with colleagues to enhance process safety and regulatory compliance

- Contribute to the training and development of junior team members

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermentation Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermentation Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fermentation Engineers play a crucial role in the biotechnology and pharmaceutical industries, overseeing the design, development, and optimization of fermentation processes used to produce various products like antibiotics, vaccines, and enzymes. Here are some of their key responsibilities:

1. Process Development and Optimization

Design and implement fermentation processes to produce target products, ensuring efficient and cost-effective manufacturing.

- Determine optimal growth conditions for microorganisms used in fermentation, including temperature, pH, and nutrient requirements.

- Develop and optimize fermentation media and culture conditions to maximize product yield and quality.

2. Equipment Design and Scale-Up

Design and oversee the installation of fermentation equipment, such as bioreactors, tanks, and ancillary systems.

- Supervise the scale-up of fermentation processes from laboratory to pilot and production scale, ensuring process integrity and productivity.

- Collaborate with engineers and technicians to design and implement process control systems for monitoring and optimizing fermentation parameters.

3. Process Monitoring and Control

Monitor and control fermentation processes in real-time to ensure product quality and yield.

- Analyze fermentation parameters, such as pH, temperature, and dissolved oxygen, to identify deviations from optimal conditions.

- Implement corrective actions to maintain process stability and troubleshoot any deviations or issues that arise during fermentation.

4. Regulatory Compliance and Safety

Ensure compliance with regulatory guidelines and safety protocols related to fermentation processes.

- Maintain accurate documentation of fermentation processes, including batch records, quality control data, and safety protocols.

- Participate in safety audits and inspections to ensure compliance with industry standards and regulations.

Interview Tips

Preparing for an interview for a Fermentation Engineer position requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company, its mission, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the position.

- Visit the company website, social media pages, and industry news sources to gather information.

- Identify the key responsibilities and requirements of the role as outlined in the job description.

2. Highlight Your Technical Expertise

During the interview, emphasize your strong technical foundation in fermentation engineering. Showcase your understanding of:

- Fermentation principles, including microbial growth, mass transfer, and bioreactor design.

- Process development and optimization techniques, such as statistical design of experiments (DOE).

- Equipment used in fermentation, including bioreactors, pumps, and control systems.

3. Demonstrate Problem-Solving and Analytical Skills

Be prepared to discuss your problem-solving and analytical abilities, as these are essential for a Fermentation Engineer. Highlight examples where you:

- Troubleshooted and resolved issues in fermentation processes, leading to improved productivity.

- Analyzed data and identified trends to optimize process parameters and increase yield.

4. Communicate Your Regulatory Knowledge

Demonstrate your understanding of regulatory requirements and safety protocols related to fermentation processes. Explain how you ensure compliance in your work.

- Discuss your experience with GMP (Good Manufacturing Practices) and other relevant regulations.

- Highlight your knowledge of safety protocols for handling microorganisms and hazardous materials.

5. Prepare Questions for the Interviewers

Asking thoughtful questions at the end of the interview shows your engagement and interest. Prepare questions that demonstrate:

- Your understanding of the company’s products and commitment to innovation.

- Your curiosity about the role’s responsibilities and potential impact.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fermentation Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.