Are you gearing up for an interview for a Fermentation Manager position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fermentation Manager and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

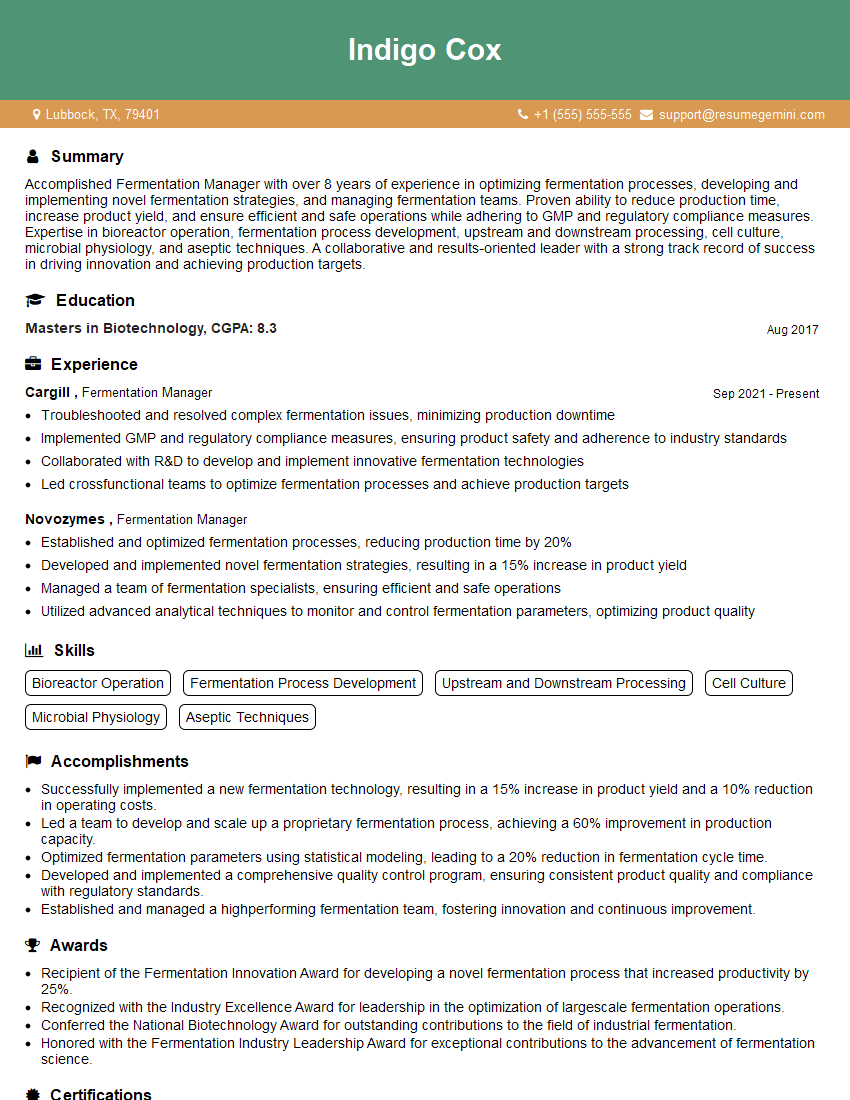

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermentation Manager

1. Describe the key performance indicators (KPIs) you track to measure the effectiveness of your fermentation process.

The key performance indicators (KPIs) I track to measure the effectiveness of my fermentation process include:

- Fermentation yield: This measures the amount of product produced per unit of substrate consumed.

- Fermentation rate: This measures the speed at which the fermentation process occurs.

- Product quality: This measures the purity, potency, and other quality attributes of the fermentation product.

- Process efficiency: This measures the amount of time, energy, and other resources required to produce the fermentation product.

- Environmental impact: This measures the impact of the fermentation process on the environment, including waste generation and energy consumption.

2. How do you optimize fermentation conditions to improve product yield and quality?

Substrate selection and preparation

- Selecting the optimal substrate for fermentation is crucial. Factors to consider include the availability, cost, and composition of the substrate.

- Properly preparing the substrate can enhance fermentation efficiency. This may involve grinding, milling, or other treatments to increase the surface area and accessibility of nutrients.

Environmental control

- Fermentation conditions such as temperature, pH, dissolved oxygen, and agitation need to be carefully controlled to optimize product yield and quality.

- Monitoring and adjusting these parameters in real-time using sensors and control systems is essential.

Strain selection and improvement

- Selecting the right strain of microorganisms for fermentation is critical. Factors to consider include the strain’s ability to produce the desired product, its tolerance to fermentation conditions, and its genetic stability.

- Strain improvement techniques such as mutagenesis and genetic engineering can be employed to enhance product yield and quality.

3. What are the common challenges encountered in fermentation processes, and how do you address them?

Common challenges encountered in fermentation processes include:

- Contamination: Contamination by unwanted microorganisms can ruin fermentation batches and lead to product spoilage. Strict adherence to sterile techniques, proper equipment maintenance, and regular monitoring are essential to prevent contamination.

- Process deviations: Deviations from optimal fermentation conditions can occur due to equipment malfunctions, human error, or changes in raw materials. Prompt detection and correction of these deviations are critical to maintain product quality and yield.

- Scale-up challenges: Scaling up fermentation processes from the laboratory to commercial production can introduce new challenges, such as maintaining sterility, controlling environmental conditions, and ensuring efficient mixing and mass transfer.

4. Discuss the role of automation and data analytics in modern fermentation processes.

Automation and data analytics play a vital role in modern fermentation processes:

- Automation: Automating fermentation processes can improve efficiency, reduce costs, and enhance safety. Automated systems can monitor and control fermentation parameters, perform data collection, and trigger corrective actions in response to deviations.

- Data analytics: Advanced data analytics techniques can be applied to fermentation data to identify trends, optimize processes, and predict outcomes. By analyzing historical data and real-time measurements, fermentation managers can gain valuable insights into process performance and make informed decisions.

5. How do you ensure the safety and regulatory compliance of fermentation processes?

Ensuring the safety and regulatory compliance of fermentation processes involves:

- Risk assessment: Identifying and evaluating potential hazards associated with fermentation processes, including biological, chemical, and physical hazards.

- Standard operating procedures (SOPs): Establishing clear and comprehensive SOPs for all fermentation activities, including equipment operation, safety protocols, and waste disposal.

- Training: Providing thorough training to personnel involved in fermentation processes to ensure they understand and follow safety procedures and regulatory requirements.

- Compliance monitoring: Regularly monitoring and auditing fermentation processes to identify and address any deviations from safety standards and regulatory guidelines.

6. Discuss the ethical considerations in fermentation technology.

Ethical considerations in fermentation technology include:

- Environmental impact: Fermentation processes can have environmental implications, such as waste generation and energy consumption. It is important to consider the environmental sustainability of fermentation operations.

- Product safety: Ensuring the safety of fermentation products for human consumption or other applications is paramount. This involves thorough testing and evaluation of product quality and safety.

- Intellectual property: Fermentation technology often involves proprietary knowledge and intellectual property. Protecting and respecting intellectual property rights is essential for ethical conduct in the field.

7. What emerging trends in fermentation technology are you most excited about?

Emerging trends in fermentation technology that I am excited about include:

- Continuous fermentation: Continuous fermentation processes offer advantages such as increased productivity, reduced waste, and better control over product quality.

- Precision fermentation: Precision fermentation utilizes genetically engineered microorganisms to produce complex molecules and high-value products more efficiently and sustainably.

- Biorefineries: Fermentation technology is being integrated with biorefineries to convert renewable biomass into valuable products, contributing to a circular bioeconomy.

8. How do you stay up-to-date on the latest advancements in fermentation technology?

I stay up-to-date on the latest advancements in fermentation technology through:

- Attending industry conferences and workshops

- Reading scientific journals and technical publications

- Networking with other fermentation professionals

- Engaging in research and development projects

9. Describe your experience in troubleshooting fermentation processes.

In my role as a Fermentation Manager, I have extensive experience in troubleshooting fermentation processes. Some common issues I have encountered and resolved include:

- Slow or incomplete fermentation

- Contamination

- Product quality defects

- Equipment failures

- Process deviations

My approach to troubleshooting involves:

- Identifying the symptoms and potential causes of the problem

- Analyzing data and performing tests to confirm the root cause

- Developing and implementing corrective actions

- Monitoring the results and making adjustments as needed

10. What are your strengths and weaknesses as a Fermentation Manager?

Strengths:

- Strong understanding of fermentation science and technology

- Proven ability to optimize fermentation processes for improved yield and quality

- Excellent troubleshooting and problem-solving skills

- Experience in managing large-scale fermentation operations

- Strong communication and interpersonal skills

Weaknesses:

- Limited experience in certain specialized fermentation techniques

- Can be overly focused on technical details at times

- Working in a fast-paced environment can sometimes lead to stress

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermentation Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermentation Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fermentation Manager is responsible for overseeing and managing the fermentation process in a brewery or other food production facility. Fermentation is a critical step in the production of many foods and beverages, and the Fermentation Manager is responsible for ensuring that the process is carried out safely, efficiently, and in accordance with established standards.

1. Job Roles

The Fermentation Manager is responsible for the following:

- Developing and implementing fermentation protocols

- Monitoring and controlling fermentation conditions

- Troubleshooting fermentation problems

- Harvesting and processing fermented products

- Maintaining fermentation equipment

- Supervising fermentation staff

2. Educational Qualification

The Fermentation Manager typically has a bachelor’s degree in food science, microbiology, or a related field. They also have several years of experience in fermentation production.

3. Skills and Expertise

The Fermentation Manager should have the following skills and expertise:

- Strong knowledge of fermentation science and technology

- Proven ability to develop and implement fermentation protocols

- Excellent troubleshooting skills

- Experience in managing fermentation staff

- Strong communication and interpersonal skills

4. Working Environment

The Fermentation Manager typically works in a laboratory or production facility. They may work long hours, including weekends and holidays.

Interview Tips

To prepare for an interview for a Fermentation Manager position, you should:

1. Research the company and the position

Make sure you understand the company’s culture and values, and the specific requirements of the position. This will help you tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions so that you can deliver them confidently and concisely.

3. Prepare questions for the interviewer

Asking questions at the end of an interview shows that you are interested in the position and that you have done your research. Prepare a few questions about the company, the position, and the interviewer’s own experience.

4. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing strong perfumes or colognes.

5. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

6. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident, friendly, and professional, and you’ll be sure to make a good impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fermentation Manager interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!