Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fermenting Cellar Dropper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fermenting Cellar Dropper so you can tailor your answers to impress potential employers.

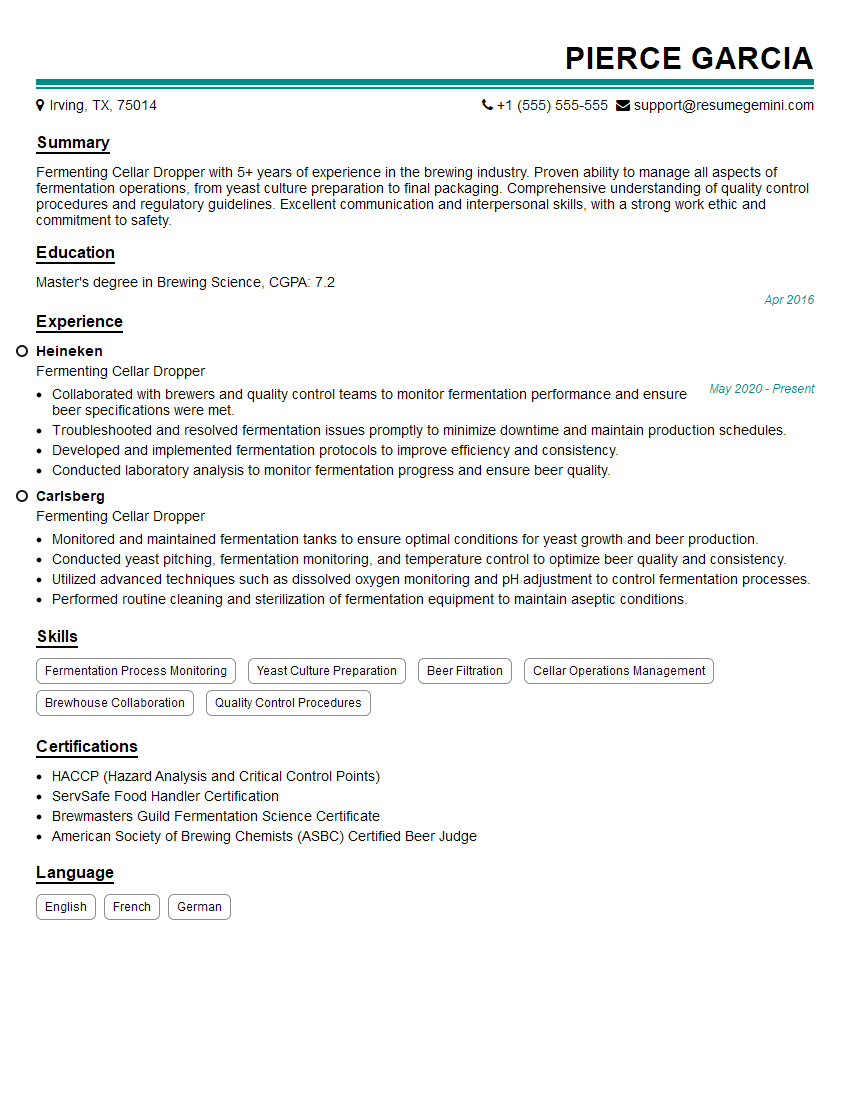

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermenting Cellar Dropper

1. Describe the process of fermentation in a winery

The process of fermentation in a winery involves converting grape juice into wine. The following steps outline the fermentation process:

- Crushing and pressing: Grapes are crushed and pressed to extract the juice.

- Adding yeast: Yeast is added to the grape juice to initiate fermentation.

- Fermentation: Yeast converts the natural sugars in the grape juice into alcohol and carbon dioxide.

- Maceration: During fermentation, the grape skins are kept in contact with the juice to extract color, flavor, and tannins.

- Aging: The wine is aged in barrels or tanks to develop its flavor and complexity.

- Bottling: The wine is bottled and left to age further before being released for consumption.

2. What are the different types of fermentation used in winemaking?

There are two main types of fermentation used in winemaking:

- Alcoholic fermentation: This is the primary fermentation where yeast converts sugars into alcohol. It is responsible for the production of wine.

- Malolactic fermentation: This secondary fermentation involves converting harsh malic acid into softer lactic acid, resulting in a smoother and more complex wine.

Other fermentation methods include carbonic maceration, which produces wines with fruity and aromatic flavors, and extended maceration, which enhances color and tannins in red wines.

3. How do you control the temperature during fermentation?

Controlling temperature during fermentation is crucial to ensure optimal yeast activity and wine quality. The following methods are used to manage temperature:

- Cooling jackets: Fermenters are equipped with cooling jackets that circulate cold water to maintain a desired temperature.

- Glycol chillers: Glycol chillers are used to cool the water that circulates through the cooling jackets.

- Fermentation in cold rooms: Fermenters are placed in temperature-controlled cold rooms to maintain a consistent temperature.

- Measuring and monitoring temperature: Temperature probes are used to monitor and adjust the fermentation temperature as needed.

4. What are the signs of a stuck fermentation?

A stuck fermentation occurs when the yeast stops converting sugars into alcohol. Signs of a stuck fermentation include:

- No further drop in specific gravity: Specific gravity should steadily decrease as fermentation progresses. If it remains stable, it may indicate a stuck fermentation.

- Slow or no carbon dioxide production: Carbon dioxide is a byproduct of fermentation. If its production slows or stops, it suggests a potential issue.

- Off-flavors or aromas: A stuck fermentation can produce undesirable flavors or aromas in the wine.

- Yeast viability test: A yeast viability test can determine if the yeast is still active or has died off.

5. How do you prevent contamination during fermentation?

Preventing contamination during fermentation is essential to maintain wine quality. The following measures are taken to minimize contamination:

- Sanitation and sterilization: All equipment, surfaces, and work areas are thoroughly sanitized and sterilized before use.

- Controlled environment: Fermentation takes place in a clean and controlled environment to reduce the risk of airborne contamination.

- Yeast selection: Healthy and robust yeast strains are selected to minimize the risk of contamination.

- Monitoring and testing: Regular monitoring and testing are conducted to detect any signs of contamination.

6. What are your responsibilities as a Fermenting Cellar Dropper?

As a Fermenting Cellar Dropper, my responsibilities include:

- Monitoring and maintaining fermentation temperatures

- Controlling yeast populations and nutrient additions

- Conducting sensory evaluations and sampling

- Assisting with yeast propagation and inoculation

- Maintaining a clean and organized work area

- Following all safety and sanitation protocols

7. What are the challenges you have faced in your previous role as a Fermenting Cellar Dropper?

In my previous role, I encountered several challenges, including:

- Managing stuck fermentations: I successfully identified and resolved stuck fermentations by implementing appropriate measures, such as yeast rehydration and temperature adjustments.

- Preventing contamination: I maintained a rigorous sanitation protocol and strict monitoring procedures to minimize the risk of contamination.

- Optimizing fermentation conditions: I conducted thorough research and consulted with experts to determine optimal fermentation conditions for different grape varieties and wine styles.

These challenges allowed me to develop problem-solving skills, enhance my technical knowledge, and improve my overall performance as a Fermenting Cellar Dropper.

8. What are your strengths and weaknesses as a Fermenting Cellar Dropper?

My strengths include:

- Technical proficiency: I have a deep understanding of fermentation processes, yeast management, and wine chemistry.

- Problem-solving skills: I am adept at identifying and resolving issues that arise during fermentation.

- Attention to detail: I am meticulous in monitoring and maintaining fermentation parameters to ensure wine quality.

- Teamwork and communication: I am an effective team player and communicator, collaborating with colleagues and supervisors to achieve common goals.

As for my weaknesses, I am continuously working on improving my:

- Time management: I am striving to enhance my time management skills to optimize my workload and meet deadlines.

- Automation knowledge: I am eager to expand my knowledge of automation systems used in modern winery operations.

9. Why are you interested in working at our winery?

I am eager to join your winery because:

- Reputation for excellence: Your winery has a well-established reputation for producing high-quality wines, and I am excited to contribute to that legacy.

- State-of-the-art facilities: I am impressed by your winery’s investment in cutting-edge equipment and technology, which will enable me to perform my duties efficiently and effectively.

- Commitment to innovation: Your winery’s commitment to research and innovation aligns with my passion for continuous learning and improvement.

- Growth opportunities: I believe that your winery provides ample opportunities for professional growth and challenges that will help me develop my skills and advance my career.

10. Do you have any questions for us?

Yes, I have a few questions:

- What is the winery’s approach to yeast management and nutrient additions during fermentation?

- Could you describe the specific automation systems used in the fermentation cellar and how they contribute to efficiency and accuracy?

- Are there any ongoing research or development projects in the winery that I could potentially contribute to?

These questions demonstrate my genuine interest in the winery’s operations, commitment to innovation, and desire to make a valuable contribution to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermenting Cellar Dropper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermenting Cellar Dropper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fermenting Cellar Dropper is a skilled professional with thorough knowledge of beer production processes and practices who specializes in managing the flow and storage of beer during primary fermentation.

1. Dropping Beer into Fermentors

Begin the fermentation process by delivering and pouring beer into fermentors.

- Operate valves and pumps to transfer beer from the brewhouse.

- Monitor flow rates and ensure accurate measurement of beer.

2. Managing Beer Temperature

Regulate and maintain optimal temperature conditions for fermentation.

- Control the temperature of the fermenting beer using cooling systems.

- Monitor temperatures and make adjustments as needed.

3. Sampling and Monitoring Fermentation

Collect samples and monitor the progress of fermentation.

- Take regular samples for laboratory analysis.

- Monitor specific gravity, pH, and other parameters to assess fermentation status.

4. Maintaining Cellar Hygiene

Ensure a clean and sanitary environment for beer fermentation.

- Clean and sanitize fermentors and related equipment.

- Follow established sanitation protocols to prevent contamination.

Interview Tips

To impress the interviewer and increase your chances of getting hired, consider the following tips:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the brewery, its products, and the specific responsibilities of the Fermenting Cellar Dropper role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on brewing trends.

2. Highlight Relevant Experience and Skills

Emphasize your experience in beer production, fermentation management, and cellar operations. If you have previous experience as a Cellar Dropper or in a similar role, be sure to highlight it.

- Quantify your accomplishments and provide specific examples.

- Explain how your skills and experience align with the job requirements.

3. Demonstrate Attention to Detail and Problem-Solving Abilities

In this role, accuracy and problem-solving are crucial. Show the interviewer that you are meticulous, organized, and capable of handling unexpected situations.

- Describe a time when you solved a problem related to fermentation or cellar management.

- Explain how you ensured the accuracy of your work and maintained high quality standards.

4. Show Passion for Beer and Brewing Science

Conveying your passion for beer and the brewing process will set you apart from other candidates. Explain what interests you about beer and why you enjoy working in the industry.

- Share your knowledge of beer styles, ingredients, and fermentation techniques.

- Discuss your interest in the science behind brewing and your desire to continuously learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fermenting Cellar Dropper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.