Are you gearing up for a career in Fermenting Cellars Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fermenting Cellars Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

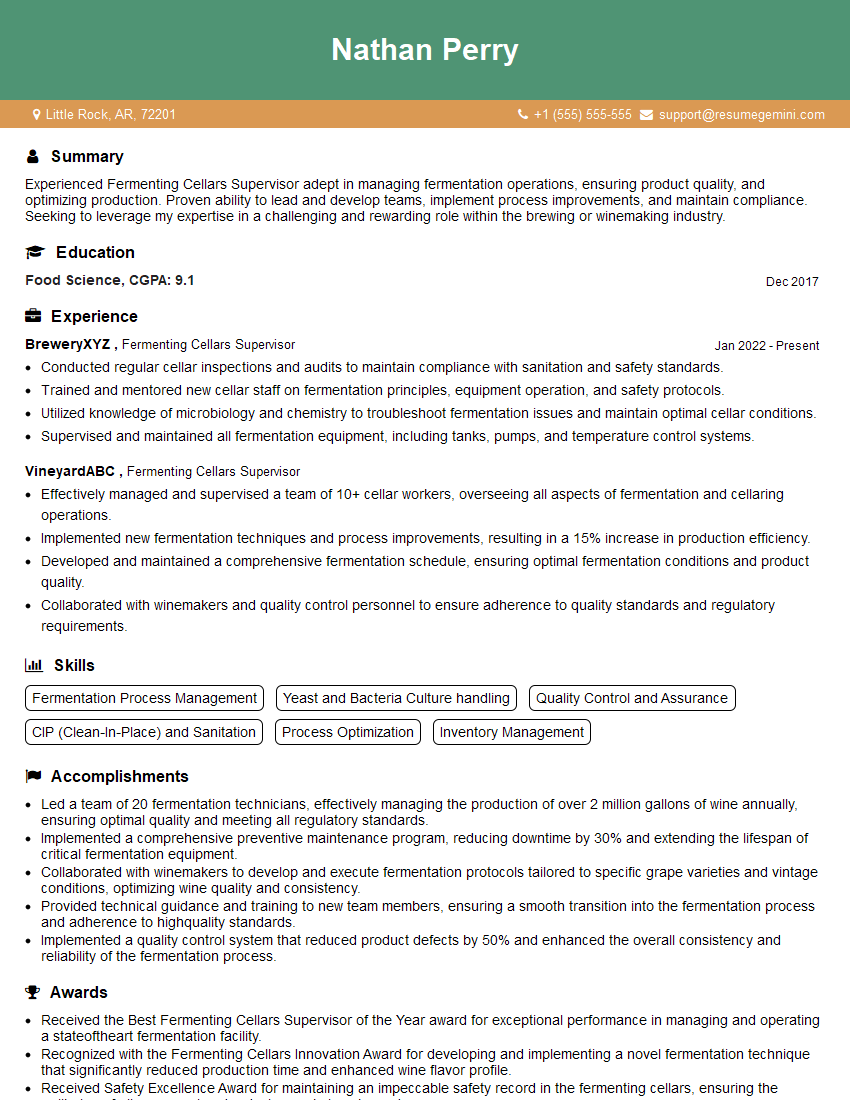

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermenting Cellars Supervisor

1. How do you ensure the accuracy and consistency of fermentation processes?

To ensure the accuracy and consistency of fermentation processes, I follow these steps:

- Establish and adhere to detailed standard operating procedures (SOPs).

- Calibrate and maintain all equipment regularly to prevent errors and ensure precise measurements.

- Monitor fermentation parameters, such as temperature, pH, and dissolved oxygen, closely and make adjustments as needed.

- Conduct regular quality checks on raw materials and finished products to ensure they meet specifications.

- Maintain a clean and sterile work environment to minimize the risk of contamination.

2. What are your strategies for optimizing fermentation yields and reducing waste?

Maximizing Fermentation Yields

- Use high-quality, viable yeast strains and optimize fermentation conditions (e.g., temperature, pH, nutrients) to promote efficient cell growth and metabolism.

- Implement fed-batch or continuous fermentation techniques to maintain optimal nutrient levels throughout the process.

- Control dissolved oxygen levels to balance the metabolic needs of the yeast.

- Monitor and adjust fermentation parameters based on real-time data analysis to prevent deviations from optimal conditions.

Reducing Waste

- Minimize dead space in fermentation vessels to reduce oxygen exposure and byproduct formation.

- Optimize cleaning and sterilization procedures to prevent contamination and extend the lifespan of equipment.

- Implement strategies such as membrane filtration or centrifugation to separate and recover valuable components from waste streams.

- Explore sustainable waste management practices, such as anaerobic digestion or composting, to minimize environmental impact.

3. Describe your experience with troubleshooting fermentation issues.

During my time as a Fermenting Cellars Supervisor at [Company Name], I encountered various fermentation issues and successfully resolved them using the following strategies:

- Identifying the root cause: Conduct thorough investigations, analyze data, and consult with technical experts to pinpoint the underlying problem.

- Developing and implementing solutions: Research potential solutions, consider their feasibility, and implement appropriate corrective actions based on scientific principles and industry best practices.

- Monitoring and evaluating outcomes: Closely monitor the effects of implemented solutions and make adjustments as needed until the issue is resolved and optimal performance is restored.

4. What is your understanding of contamination control in fermentation processes?

Contamination control in fermentation processes is critical to ensure product quality and prevent spoilage. I implement the following measures:

- Prevention: Maintain a sterile work environment, use rigorous cleaning and sanitation protocols, and implement good manufacturing practices (GMPs) to minimize the introduction of contaminants.

- Detection: Regularly conduct microbiological testing of raw materials, in-process samples, and finished products to identify and eliminate potential sources of contamination.

- Corrective actions: If contamination occurs, isolate the affected batch, investigate the root cause, and implement appropriate control measures to prevent recurrence.

5. How do you manage a team of fermentation operators and ensure their productivity and safety?

Managing Productivity

- Set clear performance goals, provide ongoing training, and empower operators to make decisions within their scope of responsibility.

- Implement performance monitoring systems to track progress, identify areas for improvement, and provide feedback to operators.

- Foster a collaborative work environment and encourage teamwork to maximize efficiency and productivity.

Ensuring Safety

- Develop and enforce comprehensive safety protocols, including training on potential hazards and emergency procedures.

- Conduct regular safety audits and inspections to identify and mitigate risks.

- Provide personal protective equipment (PPE) and ensure its proper use.

6. What is your experience with scale-up and optimization of fermentation processes?

In my previous role at [Company Name], I successfully scaled up a fermentation process from lab scale to pilot scale. I followed these steps:

- Optimized fermentation conditions based on small-scale experiments and mathematical modeling.

- Designed and implemented a pilot-scale fermentation system that accurately simulated the production environment.

- Conducted performance tests to evaluate process parameters and identify areas for improvement.

- Collaborated with engineers and technicians to implement modifications and optimize the scale-up process.

7. How do you stay up-to-date with the latest advancements in fermentation technology?

I stay up-to-date with the latest advancements in fermentation technology through the following methods:

- Attending industry conferences and workshops.

- Reading scientific journals and technical publications.

- Participating in online forums and discussion groups.

- Networking with professionals in the field.

- Conducting research and exploring emerging technologies.

8. Describe your experience with quality control and assurance in fermentation processes.

As a Fermenting Cellars Supervisor, I am responsible for ensuring the quality and safety of our fermentation products. I implement the following quality control and assurance measures:

- Establish and maintain quality standards and specifications.

- Conduct regular inspections and testing to monitor product quality.

- Implement corrective actions to address any quality deviations.

- Maintain traceability throughout the fermentation process.

- Collaborate with the quality assurance department to ensure adherence to regulatory requirements.

9. How do you handle unforeseen challenges and emergencies in the fermentation process?

In the event of unforeseen challenges or emergencies, I follow these steps:

- Assess the situation quickly and calmly.

- Activate the emergency response plan.

- Communicate with the appropriate personnel and authorities.

- Take necessary actions to mitigate the risks and minimize the impact.

- Investigate the root cause and implement preventive measures to avoid similar incidents in the future.

10. How do you contribute to the continuous improvement of fermentation processes?

I am committed to continuous improvement and actively contribute in the following ways:

- Monitor fermentation processes closely and identify areas for optimization.

- Conduct research and explore innovative technologies.

- Collaborate with colleagues and external experts to share knowledge and best practices.

- Implement process improvements and evaluate their effectiveness.

- Provide training and support to staff to enhance their skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermenting Cellars Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermenting Cellars Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assist in the management and supervision of the fermenting cellars

1. Production

Assist in the preparation of must, including weighing, crushing, and pressing

- Assist in the operation of fermentation vessels

- Assist in the monitoring and control of fermentation

2. Quality Control

Assist in the monitoring and control of fermentation temperature, pH, and specific gravity

- Assist in the sampling and analysis of fermenting must

- Assist in the troubleshooting of fermentation issues

3. Cellar Maintenance

Assist in the cleaning and sanitizing of fermentation vessels

- Assist in the maintenance of cellar equipment

- Assist in the preparation of the cellar for the next fermentation

4. Safety

Adhere to all safety policies and procedures

- Assist in the training of new employees

- Assist in the supervision of the cellar

Interview Tips

The key to acing an interview is to be prepared. This means doing your research on the company, the position, and the industry. It also means practicing your answers to common interview questions. Here are a few tips to help you prepare for your interview for a Fermenting Cellars Supervisor position:

1. Research the Company

Visit the company’s website and read about their history, mission, and values. This will give you a good understanding of the company’s culture and what they are looking for in a Fermenting Cellars Supervisor.

2. Research the Position

Read the job description carefully and make a list of the key responsibilities. Then, think about your own experience and skills and how they match up with the requirements of the position. Highlight your most relevant experience and skills in your resume and cover letter.

3. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

4. Be Enthusiastic and Positive

The interviewer wants to see that you are excited about the position and the company. Be enthusiastic and positive in your answers and show that you are eager to learn more about the company and the position.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fermenting Cellars Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fermenting Cellars Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.