Are you gearing up for a career in Fiber Optic Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fiber Optic Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

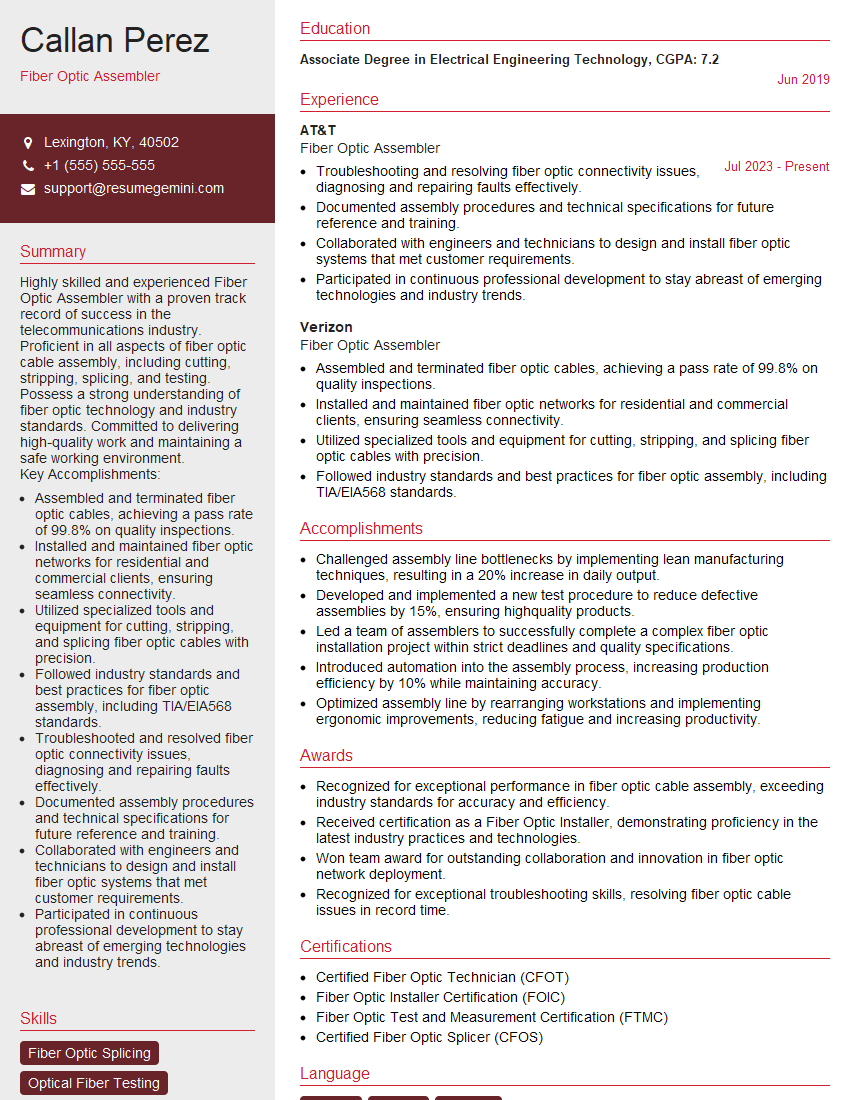

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiber Optic Assembler

1. Explain the process of fiber optic cable assembly.

The process of fiber optic cable assembly involves several steps, including:

- Cable selection: Choosing the appropriate type of fiber optic cable based on the application and performance requirements.

- Connectorization: Attaching connectors to the ends of the fiber optic cable using specialized equipment.

- Testing: Verifying the performance of the assembled cable using optical time-domain reflectometry (OTDR) and other testing methods.

- Documentation: Completing necessary documentation, including assembly instructions, test results, and quality assurance reports.

2. Describe the different types of fiber optic connectors and their applications.

There are various types of fiber optic connectors, each designed for specific applications:

- SC connector: A snap-in connector commonly used in data centers and telecommunications equipment.

- LC connector: A latching connector with a small form factor, ideal for high-density applications.

- MTP connector: A multi-fiber connector that allows for parallel transmission of multiple fibers simultaneously.

- E2000 connector: A ruggedized connector designed for harsh environments, such as industrial settings.

3. How do you ensure the quality of your fiber optic cable assemblies?

To ensure quality, I adhere to the following practices:

- Vendor selection: Partnering with reputable suppliers to obtain high-quality materials.

- Process control: Implementing standardized assembly procedures and using calibrated equipment.

- Testing: Conducting rigorous testing at each stage of the assembly process to identify and eliminate defects.

- Inspection: Performing visual inspections to ensure the physical integrity of the assemblies.

4. Discuss the importance of cleanliness in fiber optic cable assembly.

Cleanliness is crucial in fiber optic assembly as contaminants can significantly degrade the signal quality:

- Dust and debris: Can block light transmission and cause attenuation.

- Oils and solvents: Can damage the fiber optic cable or interfere with the bonding process.

5. Explain the optical loss budget and how you calculate it for a given assembly.

The optical loss budget is the maximum allowable optical loss for a fiber optic link. To calculate it, I consider the following factors:

- Cable loss: The loss due to the length and type of fiber optic cable used.

- Connector loss: The loss introduced by the connectors at each end of the cable.

- Splice loss: If splicing is required, the loss due to the splices.

- Margin: A safety margin is added to account for unforeseen losses and ensure reliable performance.

6. What are the safety precautions you take when working with fiber optics?

I prioritize safety by adhering to the following precautions:

- Eye protection: Wearing safety glasses or goggles to protect my eyes from laser radiation.

- Sharp object handling: Using proper techniques when handling sharp tools and fiber optic shards.

- Electrical safety: Ensuring that all equipment is properly grounded and handling electrical components safely.

7. How do you troubleshoot common fiber optic cable problems?

When troubleshooting fiber optic cable problems, I follow a systematic approach:

- Visual inspection: Checking for physical damage or dirt on the cable and connectors.

- OTDR testing: Using an optical time-domain reflectometer to locate faults and measure signal attenuation.

- Continuity testing: Verifying the continuity of the fiber optic cable using a light source and power meter.

8. Describe the different types of fiber optic polishing techniques.

Various polishing techniques are used to prepare fiber optic connectors for optimal performance:

- Mechanical polishing: Using abrasive pads or films to polish the fiber end face.

- Chemical-mechanical polishing (CMP): Combining mechanical polishing with chemical etching for finer finishes.

- Laser polishing: Utilizing a laser to precisely remove material and achieve a smooth surface.

9. Explain the concept of fiber optic splicing and its applications.

Fiber optic splicing involves joining two fiber optic cables to create a continuous optical path:

- Fusion splicing: Using an electric arc to melt and fuse the fiber ends together, resulting in a permanent and low-loss joint.

- Mechanical splicing: Employing a mechanical device to align and hold the fiber ends together, without melting.

10. What are the emerging trends in fiber optic cable assembly?

The fiber optic cable assembly industry is constantly evolving, with key trends emerging:

- High-speed interconnects: Increasing demand for fiber optic assemblies capable of handling high data rates.

- Miniaturization: Development of smaller and more compact fiber optic assemblies.

- Automation: Adoption of automated assembly processes to enhance efficiency and precision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiber Optic Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiber Optic Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiber Optic Assemblers are responsible for assembling and testing fiber optic cables and components. Their work is essential for ensuring the transmission of high-speed data and communication signals.

1. Cable Assembly

Fiber Optic Assemblers assemble fiber optic cables by connecting individual fibers to connectors. They use specialized equipment and techniques to ensure that the connections are secure and meet industry standards.

- Identify and prepare fiber optic cables and connectors

- Use specialized tools and equipment to connect fibers to connectors

2. Component Assembly

Fiber Optic Assemblers also assemble fiber optic components, such as couplers, splitters, and attenuators. They must have a thorough understanding of the function and performance of these components to ensure they are assembled correctly.

- Identify and prepare fiber optic components

- Assemble components using precise techniques and equipment

3. Testing and Inspection

Fiber Optic Assemblers test and inspect assembled cables and components to ensure they meet specifications. They use specialized equipment to measure optical loss, return loss, and other parameters.

- Conduct tests to verify performance and quality of assemblies

- Identify and correct any defects or non-conformances

4. Documentation

Fiber Optic Assemblers maintain detailed documentation of their work, including assembly instructions, test results, and any modifications made. This documentation is essential for quality control and troubleshooting.

- Prepare and maintain assembly instructions and test reports

- Document any modifications or repairs made to assemblies

Interview Tips

Preparing for an interview for a Fiber Optic Assembler position is crucial. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company you’re applying to and the specific Fiber Optic Assembler position. This will demonstrate your interest and understanding of the role.

- Visit the company’s website to learn about their products, services, and culture.

- Review the job description carefully to identify the required skills and responsibilities.

2. Practice Your Answers

Take time to practice your answers to common interview questions. This will help you feel confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and why you’re interested in the position.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the Fiber Optic Assembler position. Be specific and provide concrete examples of your work.

- Discuss your experience in assembling fiber optic cables and components.

- Highlight your knowledge of fiber optic testing and inspection techniques.

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. It also gives you an opportunity to clarify any information or ask about the company’s culture.

- Ask questions about the specific projects you would be working on.

- Inquire about the company’s training and development opportunities.

5. Follow Up

After the interview, send a brief thank-you note to the interviewer. This shows your appreciation and continued interest in the position. You can also reiterate your key qualifications and express your enthusiasm for the job.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fiber Optic Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.