Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiber Product Cutting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

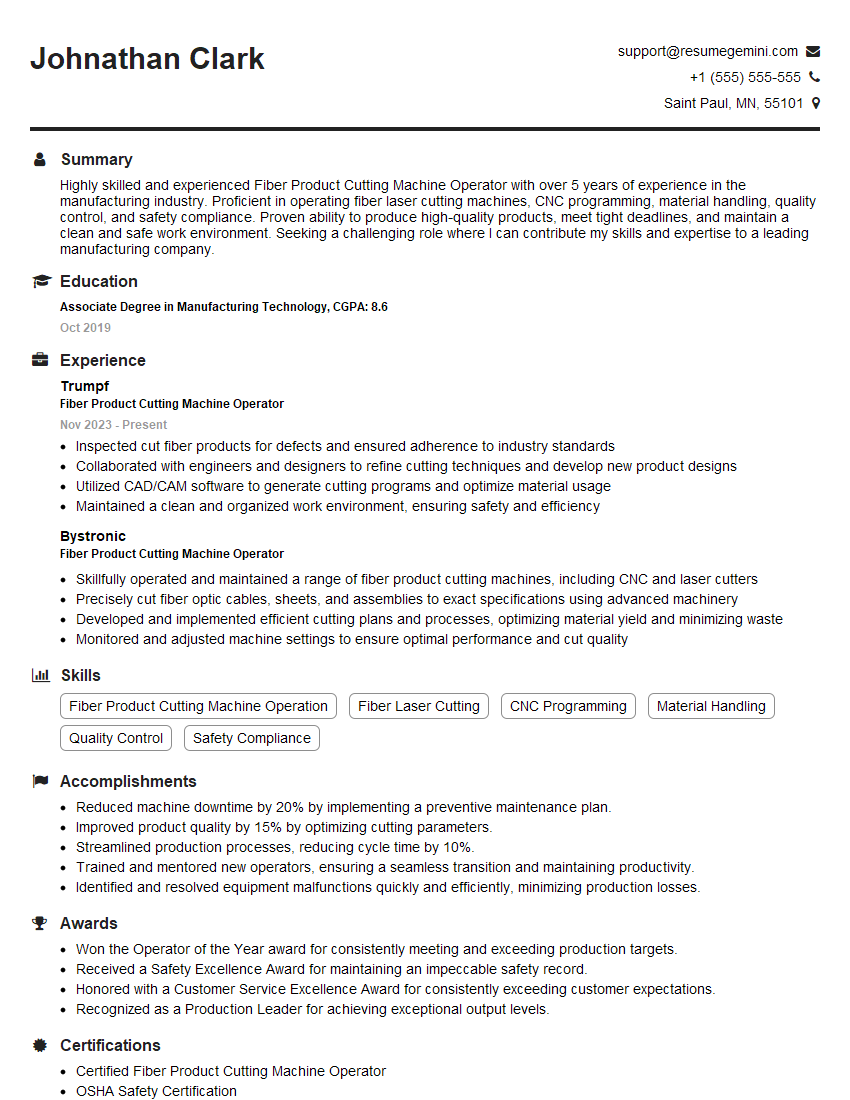

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiber Product Cutting Machine Operator

1. Explain the different types of fiber products that can be cut using a fiber product cutting machine?

There are numerous types of fiber products that can be cut using a fiber product cutting machine, some common types include:

- Fiberglass

- Carbon fiber

- Aramid fiber

- Natural fibers (such as cotton, flax, and jute)

- Synthetic fibers (such as polyester, nylon, and acrylic)

2. What are the key factors to consider when selecting the right blade for a fiber product cutting machine?

Blade material:

- The material of the blade will determine its durability, sharpness, and resistance to wear.

- Common blade materials include high-speed steel, carbide, and diamond.

Blade geometry:

- The geometry of the blade will affect the quality of the cut.

- Factors to consider include the blade angle, rake angle, and clearance angle.

Blade thickness:

- The thickness of the blade will affect the cutting force and the width of the kerf.

- Thicker blades are more durable but require more force to cut.

3. How do you ensure that the fiber product cutting machine is operating safely and efficiently?

To ensure the safe and efficient operation of a fiber product cutting machine, it is important to:

- Follow the manufacturer’s instructions for operation and maintenance.

- Inspect the machine regularly for any signs of damage or wear.

- Keep the machine clean and free of debris.

- Use sharp blades and replace them when they become dull.

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

4. What are the common troubleshooting procedures for a fiber product cutting machine?

Some common troubleshooting procedures for a fiber product cutting machine include:

- Checking the power supply to ensure that the machine is receiving power.

- Inspecting the blade to ensure that it is sharp and properly installed.

- Checking the material being cut to ensure that it is compatible with the machine.

- Adjusting the cutting speed and pressure to optimize the cut quality.

- Cleaning the machine to remove any debris that may be interfering with its operation.

5. How do you handle delicate materials when cutting them with a fiber product cutting machine?

To handle delicate materials when cutting them with a fiber product cutting machine, it is important to:

- Use a sharp blade to minimize tearing and fraying.

- Use a light touch when cutting to avoid damaging the material.

- Support the material on both sides of the cut to prevent it from bending or warping.

- Use a vacuum cleaner to remove any dust or debris from the cutting area.

6. What are the different types of cuts that can be made with a fiber product cutting machine?

The different types of cuts that can be made with a fiber product cutting machine include:

- Straight cuts

- Bevel cuts

- Compound cuts

- Curved cuts

- Nested cuts

7. How do you maintain the accuracy of a fiber product cutting machine?

To maintain the accuracy of a fiber product cutting machine, it is important to:

- Calibrate the machine regularly using a precision measuring device.

- Inspect the machine regularly for any signs of wear or damage.

- Use high-quality materials and sharp blades.

- Follow the manufacturer’s instructions for operation and maintenance.

8. What are the safety precautions that should be taken when operating a fiber product cutting machine?

The safety precautions that should be taken when operating a fiber product cutting machine include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Keeping the work area clean and free of debris.

- Never reaching into the cutting area while the machine is in operation.

- Unplugging the machine before performing any maintenance or repairs.

9. What are the different types of software that can be used to program a fiber product cutting machine?

The different types of software that can be used to program a fiber product cutting machine include:

- CAD/CAM software

- Nesting software

- Optimization software

- Simulation software

10. How do you troubleshoot a fiber product cutting machine that is not cutting properly?

To troubleshoot a fiber product cutting machine that is not cutting properly, it is important to:

- Check the blade to ensure that it is sharp and properly installed.

- Check the material being cut to ensure that it is compatible with the machine.

- Adjust the cutting speed and pressure to optimize the cut quality.

- Clean the machine to remove any debris that may be interfering with its operation.

- Contact the manufacturer’s technical support for assistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiber Product Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiber Product Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiber Product Cutting Machine Operators are responsible for operating and maintaining a variety of high-speed fiber product cutting machines. These machines use lasers, knives, or water jets to cut precision shapes and patterns into fiber products. Operators must have a thorough understanding of the equipment and materials they work with, as well as the ability to follow detailed instructions and work independently.

1. Operate and Maintain Cutting Machines

Operators are responsible for setting up, operating, and maintaining the fiber product cutting machines. This includes loading and unloading materials, adjusting machine settings, and monitoring machine operation. They must also perform regular maintenance on the machines, such as cleaning and lubrication.

2. Inspect Finished Products

Operators are responsible for inspecting finished products to ensure that they meet specifications. This includes checking for accuracy, quality, and completeness. They must also identify and correct any defects.

3. Follow Quality Control Procedures

Operators must follow established quality control procedures to ensure that all products meet the required standards. This includes maintaining records and documenting any problems or corrective actions.

4. Troubleshoot and Resolve Problems

Operators must be able to troubleshoot and resolve any problems that may arise with the equipment or materials. This includes identifying the cause of the problem and taking corrective action.

Interview Tips

Preparing for an interview for a Fiber Product Cutting Machine Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You should also familiarize yourself with the industry and the latest trends in fiber product cutting technology.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and succinctly. You should also prepare questions to ask the interviewer, which demonstrates your interest in the position and the company.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for an office setting. You should also avoid wearing excessive jewelry or perfume.

4. Be Punctual

Punctuality is a sign of respect for the interviewer’s time. Plan your route to the interview location in advance so that you can arrive on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and open about your skills and experience, and be prepared to talk about your goals and aspirations.

- Example Outline

- Majority of my experience has been in operating fiber product cutting machines.

- I have a strong understanding of the equipment and materials used in this industry.

- I am proficient in following detailed instructions and working independently.

- I am also a team player and have experience working in a fast-paced environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiber Product Cutting Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.