Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fiber Technologist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fiber Technologist so you can tailor your answers to impress potential employers.

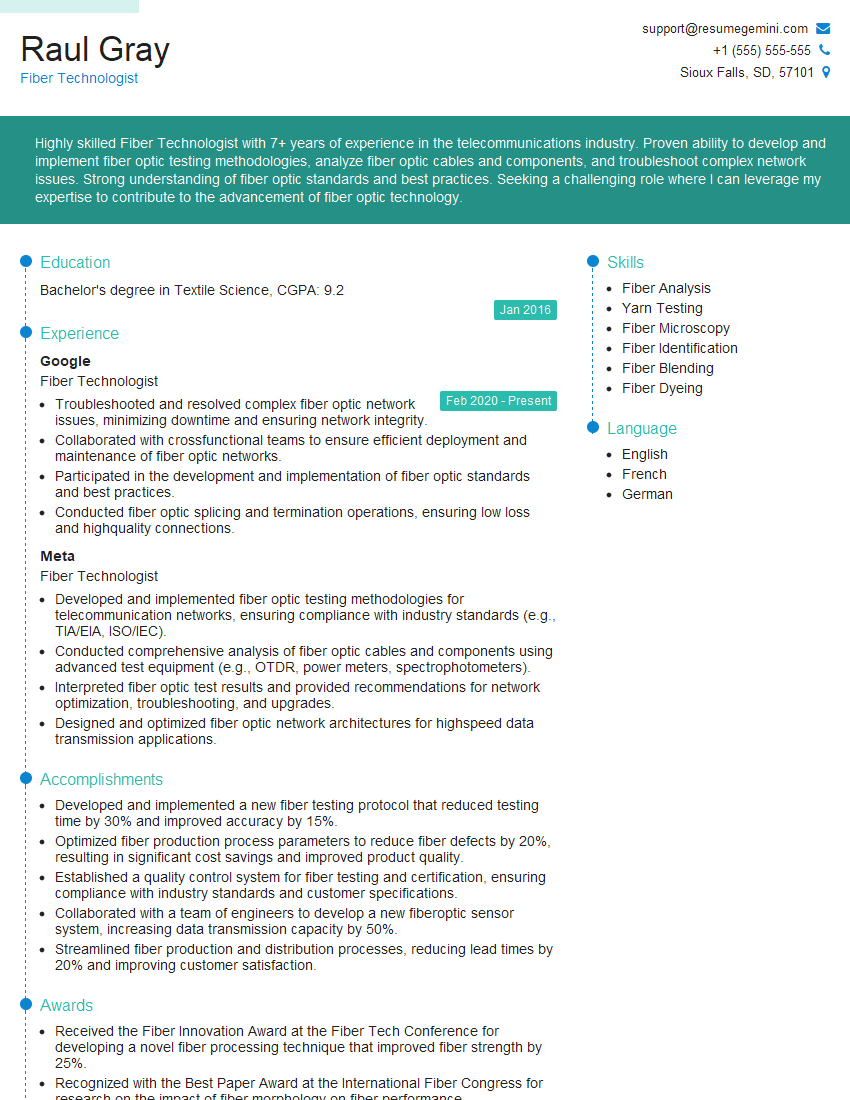

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiber Technologist

1. Describe the different types of fiber and their applications in the textile industry?

Natural Fibers

- Cotton: Soft, absorbent, and breathable; used in clothing, bedding, and home textiles.

- Wool: Strong, warm, and moisture-wicking; used in clothing, carpets, and insulation.

- Silk: Luxurious, soft, and wrinkle-resistant; used in high-end clothing, scarves, and lingerie.

Synthetic Fibers

- Polyester: Durable, wrinkle-resistant, and moisture-repellent; used in clothing, sportswear, and home furnishings.

- Nylon: Strong, elastic, and abrasion-resistant; used in sportswear, swimwear, and ropes.

- Acrylic: Soft, warm, and hypoallergenic; used in clothing, blankets, and carpets.

Cellulosic Fibers

- Rayon: Soft, absorbent, and breathable; used in clothing, bedding, and surgical dressings.

- Tencel: Strong, absorbent, and biodegradable; used in clothing, home textiles, and medical applications.

2. Explain the process of yarn manufacturing, from fiber preparation to twisting?

Fiber Preparation

- Cleaning: Removing impurities from fibers to improve yarn quality.

- Opening: Separating fibers into individual strands to create a loose, fluffed mass.

- Carding: Removing short fibers, aligning long fibers, and creating a continuous strand.

Spinning

- Drawing: Attenuating and aligning fibers to form a thin, continuous sliver.

- Roving: Combining multiple slivers to create a thicker, more cohesive strand.

- Spinning: Twisting the roving to create a yarn with the desired strength and elasticity.

Twisting

- Single twisting: Twisting the yarn in one direction to increase strength.

- Two-ply twisting: Twisting two yarns together in opposite directions to create a stronger, more durable yarn.

3. Describe the various testing methods used to evaluate the physical properties of fibers?

- Tensile strength: Measuring the force required to break a fiber.

- Elongation: Measuring the amount a fiber stretches before breaking.

- Wicking: Measuring the ability of a fiber to absorb and transport moisture.

- Pilling: Evaluating the tendency of a fabric to form small, entangled balls on its surface.

- Fade resistance: Testing how well a fiber retains its color when exposed to light or other environmental factors.

4. Explain the role of fiber morphology in determining the properties of a fabric?

- Fiber length: Longer fibers produce stronger, more durable fabrics.

- Fiber fineness: Thinner fibers improve softness and drape.

- Fiber shape: Cross-sectional shape affects fabric texture and handle.

- Fiber orientation: Arrangement of fibers in a fabric influences properties such as strength and elasticity.

5. Describe the different methods of fabric construction, such as weaving, knitting, and nonwovens?

Weaving

- Interlacing vertical (warp) and horizontal (weft) yarns to create a grid-like structure.

- Produces durable, stable fabrics with a wide range of textures.

Knitting

- Looping yarns together to create a flexible, elastic fabric.

- Produces soft, breathable fabrics for clothing, sportswear, and home textiles.

Nonwovens

- Bonding fibers together without using traditional weaving or knitting techniques.

- Produces lightweight, disposable fabrics for applications such as wipes, surgical gowns, and insulation.

6. Explain the principles of dyeing and printing on textiles?

Dyeing

- Immersing fabrics in a dye solution to absorb color.

- Factors affecting color include dye type, temperature, pH, and time.

Printing

- Applying color to specific areas of a fabric using screens, rollers, or ink-jet technology.

- Techniques include direct printing, transfer printing, and digital printing.

7. Discuss the challenges and advancements in sustainable fiber production?

Challenges

- Environmental impact of natural fiber production (e.g., water consumption, pesticide use).

- Limited availability and high cost of sustainable synthetic fibers.

Advancements

- Development of eco-friendly natural fiber processing techniques.

- Production of biodegradable and bio-based synthetic fibers.

- Promoting circular and closed-loop production systems.

8. Describe the role of fiber technologists in the development and innovation of textile products?

- Analyze fiber properties and develop new fibers with improved performance.

- Optimize yarn manufacturing and fabric construction techniques for specific applications.

- Conduct research and development to create innovative textile materials and products.

9. Explain the quality control measures implemented in a textile manufacturing facility?

- Raw material inspection: Ensuring fibers meet specifications and are free from defects.

- Process control: Monitoring production parameters to maintain quality and efficiency.

- Fabric testing: Evaluating fabric properties such as strength, colorfastness, and shrinkage.

- Statistical analysis: Using statistical techniques to identify and eliminate quality issues.

10. Discuss the ethical considerations in fiber and textile production?

- Ensuring fair and safe working conditions for employees.

- Minimizing environmental impact throughout the production process.

- Promoting transparency and traceability in the supply chain.

- Complying with health and safety regulations and industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiber Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiber Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

A Fiber Technologist plays a significant role in optimizing the production process of textile fibers, ensuring their quality, and meeting industry standards.

1. Fiber Analysis and Characterization

Responsible for conducting thorough analyses of various fibers to determine their physical, chemical, and mechanical properties. These analyses aid in fiber selection, process optimization, and product development.

- Conducts fiber testing using advanced instrumentation, such as microscopes, spectrometers, and tensile testers.

- Evaluates fiber properties, including fiber diameter, length, strength, crimp, and elongation.

2. Process Troubleshooting and Optimization

Analyzes production processes to identify areas for improvement and optimize fiber quality. Troubleshoots issues related to fiber breakage, contamination, and other production inefficiencies.

- Collaborates with production teams to implement process modifications based on fiber analysis results.

- Develops and implements quality control measures to maintain consistency in fiber properties.

3. Product Development

Involved in developing new fiber products and improving existing ones. Explores innovative fiber technologies and materials to enhance product performance and meet customer requirements.

- Conducts research on fiber blends, finishes, and treatments to enhance fiber properties.

- Works with designers and marketing teams to translate fiber characteristics into marketable products.

4. Industry Standards and Regulations

Stays abreast of industry standards and regulations related to fiber production, quality, and safety. Ensures compliance with these regulations and guidelines.

- Conducts regular audits and inspections to verify adherence to industry standards.

- Participates in industry organizations and committees to stay updated on best practices and emerging technologies.

Interview Tips

Preparing for a Fiber Technologist interview requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry reputation. Research the latest advancements in fiber technology and industry trends.

- Visit the company website and LinkedIn page.

- Read industry publications and attend webinars to stay informed.

2. Highlight Your Technical Expertise

Emphasize your strong understanding of fiber science, analysis techniques, and production processes. Quantify your experience and provide examples of your technical accomplishments.

- Describe your experience using fiber testing equipment and analyzing fiber properties.

- Discuss your involvement in process optimization projects and the outcomes achieved.

3. Demonstrate Your Problem-Solving Skills

Showcase your ability to analyze problems, identify root causes, and develop solutions in a production environment. Provide examples of how you have resolved fiber-related issues and improved production efficiency.

- Share an experience where you identified a fiber contamination issue and implemented corrective actions.

- Explain how you troubleshoot and resolve fiber breakage problems.

4. Discuss Your Research Experience

If applicable, highlight your involvement in fiber-related research projects or publications. This demonstrates your passion for the field and your willingness to stay at the forefront of innovation.

- Describe your research on fiber blends or treatments and the results obtained.

- Discuss your contributions to conference presentations or journal publications.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also provides an opportunity to clarify any aspects of the job or company culture.

- Ask about the company’s commitment to fiber innovation and sustainability.

- Inquire about the scope of the role and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiber Technologist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!