Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Autobody Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

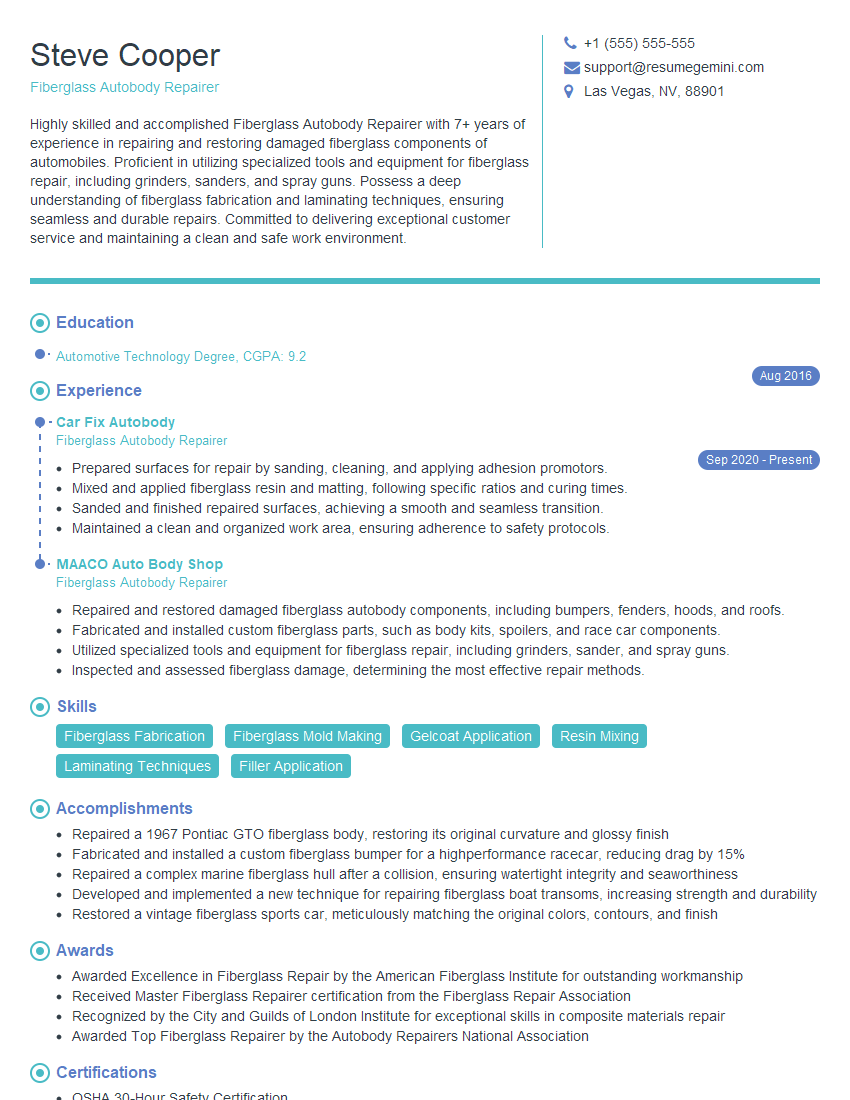

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Autobody Repairer

1. What are the different types of fiberglass autobody repair materials and their uses?

- Fiberglass cloth: A woven fabric made from fiberglass threads. It is used to reinforce and repair damaged fiberglass surfaces.

- Fiberglass mat: A non-woven material made from chopped fiberglass strands. It is used to fill gaps and create smooth surfaces.

- Fiberglass resin: A liquid resin that is used to bind fiberglass materials together. It comes in different types, such as polyester, epoxy, and vinyl ester.

- Gelcoat: A pigmented resin that is used to create a smooth, protective finish on fiberglass surfaces.

2. How do you prepare a fiberglass surface for repair?

Surface cleaning

- Clean the damaged area with a degreaser to remove dirt and oil.

- Sand the area to roughen the surface and create a good bond for the repair materials.

Area preparation

- Mask off the surrounding area to protect it from the repair materials.

- Cut a piece of fiberglass cloth or mat to the size of the damaged area.

3. What are the steps involved in laminating fiberglass materials?

Laminating fiberglass involves layering fiberglass cloth or mat with resin to create a strong and durable repair.

- Apply a thin layer of resin to the prepared surface.

- Place the fiberglass cloth or mat over the resin and smooth it out.

- Apply more resin to the fiberglass material and work it in with a roller or brush.

- Repeat the process until the desired thickness is achieved.

- Allow the laminate to cure according to the manufacturer’s instructions.

4. How do you repair a crack in a fiberglass autobody panel?

- Clean and prepare the area around the crack.

- Drill a small hole at each end of the crack to prevent it from spreading.

- Use a grinder to widen and deepen the crack.

- Laminate fiberglass cloth or mat over the crack, extending the repair beyond the edges of the crack.

- Sand the repaired area and apply gelcoat to create a smooth finish.

5. How do you repair a hole in a fiberglass autobody panel?

- Clean and prepare the area around the hole.

- Cut a piece of fiberglass cloth or mat to the size of the hole and overlap the edges by at least 1 inch.

- Apply resin to the hole and the back of the fiberglass patch.

- Place the fiberglass patch over the hole and smooth it out.

- Apply more resin to the fiberglass patch and work it in with a roller or brush.

- Allow the repair to cure and then sand it flush with the surrounding surface.

6. What are some common problems that can occur during fiberglass autobody repair and how do you troubleshoot them?

- Air bubbles: Air bubbles can be trapped in the laminate if it is not properly worked in. To troubleshoot, use a roller or brush to work the resin into the fiberglass material and remove any trapped air.

- Delamination: Delamination occurs when the fiberglass layers separate from each other. To troubleshoot, clean and roughen the surfaces of the delaminated areas and re-laminate them.

- Cracking: Cracks can occur if the fiberglass is not properly cured or if it is subjected to excessive stress. To troubleshoot, grind out the crack and re-laminate the area.

7. What are some safety precautions that should be taken when working with fiberglass autobody repair materials?

- Wear gloves, eye protection, and a respirator to protect yourself from fiberglass dust and fumes.

- Work in a well-ventilated area to avoid inhaling fiberglass dust and fumes.

- Do not smoke or use open flames near fiberglass materials as they are flammable.

- Dispose of fiberglass waste properly according to local regulations.

8. What are some of the latest trends in fiberglass autobody repair?

- Vacuum infusion: A technique that uses a vacuum to remove air from the laminate during the curing process, resulting in a stronger and lighter repair.

- Pre-preg materials: Fiberglass materials that are pre-impregnated with resin, making them easier to work with and reducing the risk of air bubbles.

- Nanotechnology: The use of nanoparticles in fiberglass materials to improve their strength, durability, and resistance to chemicals.

9. What are some of the challenges you have faced in your previous fiberglass autobody repair jobs?

Some challenges I have faced in my previous fiberglass autobody repair jobs include:

- Repairing large and complex damage

- Matching the color and texture of the original finish

- Working on vehicles with tight clearances

- Meeting deadlines while maintaining high quality standards

10. What are your strengths and weaknesses as a fiberglass autobody repairer?

Some of my strengths as a fiberglass autobody repairer include:

- Strong technical skills in fiberglass repair techniques

- Attention to detail and commitment to quality

- Ability to work independently and as part of a team

- Excellent problem-solving and troubleshooting skills

Some areas where I could improve include:

- Expanding my knowledge of new fiberglass repair technologies

- Gaining experience in repairing more complex types of damage

- Improving my time management skills to meet tight deadlines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Autobody Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Autobody Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Autobody Repairers are responsible for repairing and restoring damaged fiberglass autobody parts. The key responsibilities of a Fiberglass Autobody Repairer include but not limited to:

1. Repairing damaged fiberglass autobody parts.

This involves assessing the damage, determining the best course of action, and then repairing the part using fiberglass and other materials.

- Inspecting damaged fiberglass autobody parts to determine the extent of the damage

- Selecting the appropriate materials and tools for the repair

- Preparing the damaged area for repair by sanding, cleaning, and masking

- Applying fiberglass and other materials to repair the damaged area

- Sanding and finishing the repaired area to match the surrounding surface

2. Replacing damaged fiberglass autobody parts.

This involves removing the damaged part, installing a new part, and then finishing the installation.

- Removing damaged fiberglass autobody parts

- Installing new fiberglass autobody parts

- Finishing the installation by sanding, painting, and detailing the new part

3. Maintaining a clean and organized work area.

This involves keeping the work area clean of debris, tools, and materials. It also involves maintaining the equipment in good working order.

- Keeping the work area clean of debris, tools, and materials

- Maintaining the equipment in good working order

- Following safety procedures

4. Providing excellent customer service.

This involves being courteous, helpful, and responsive to customer needs. It also involves keeping customers informed of the progress of their repairs.

- Being courteous, helpful, and responsive to customer needs

- Keeping customers informed of the progress of their repairs

- Ensuring that customers are satisfied with the finished product

Interview Tips

Preparing for an interview can be daunting, but it is important to remember that the interviewer is looking for someone who is qualified and passionate about the position. Here are some tips to help you ace your interview for a Fiberglass Autobody Repairer position:

1. Research the company and the position.

This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company. You can research the company’s website, social media pages, and Glassdoor reviews. You can also search for news articles about the company to learn about its recent accomplishments and challenges.

2. Practice answering common interview questions.

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience and skills.

The interviewer will want to know about your experience as a Fiberglass Autobody Repairer. Be prepared to talk about your skills and experience in repairing and replacing fiberglass autobody parts. You should also be able to provide examples of your work.

4. Be enthusiastic and positive.

The interviewer will be looking for someone who is enthusiastic and passionate about the position. Be sure to show your enthusiasm for the position and your desire to work for the company.

5. Dress professionally.

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

6. Be on time.

Punctuality is important in any interview, but it is especially important in an interview for a Fiberglass Autobody Repairer position. This shows the interviewer that you are reliable and that you respect their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fiberglass Autobody Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.