Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Bonding Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

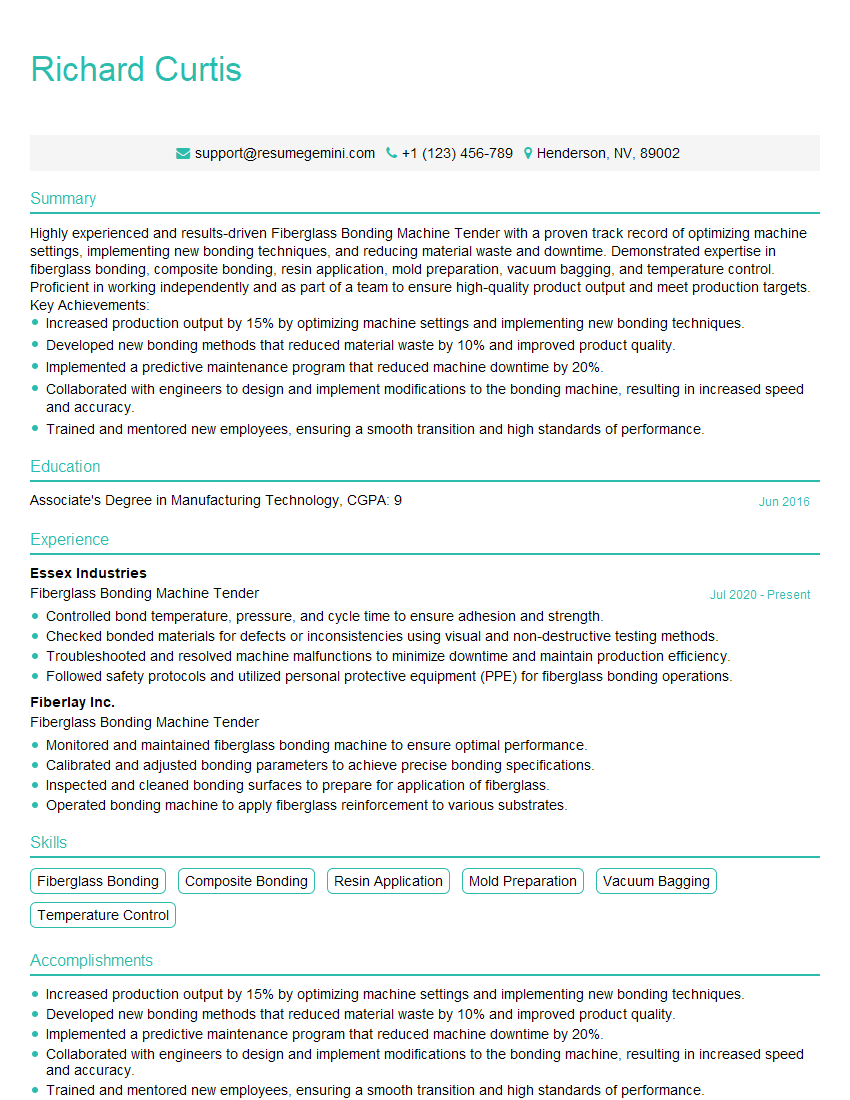

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Bonding Machine Tender

1. Describe the process of bonding fiberglass materials using a fiberglass bonding machine?

- Prepare the fiberglass materials by cleaning and sanding them.

- Apply a thin layer of adhesive to the bonding surfaces.

- Place the materials in the bonding machine and align them properly.

- Start the machine and apply pressure to bond the materials.

- Cure the bond by heating it or applying pressure for a specified amount of time.

2. How do you adjust the bonding machine for different types of fiberglass materials?

Adjusting pressure:

- Thicker materials require higher pressure.

- More delicate materials require lower pressure.

Adjusting temperature:

- Some adhesives require heat to cure.

- Temperature settings vary depending on the adhesive used.

Adjusting speed:

- Faster speeds can increase efficiency.

- Slower speeds may be necessary for complex or delicate materials.

3. What are the safety precautions you must observe when operating a fiberglass bonding machine?

- Wear appropriate safety gear (gloves, safety glasses).

- Keep the work area well-ventilated.

- Follow the manufacturer’s instructions for the machine and adhesives.

- Do not touch the bonding surfaces while the machine is running.

- Be aware of the potential for burns or eye injuries.

4. Describe the types of defects that can occur during fiberglass bonding and how to prevent them?

- Voids: Caused by insufficient pressure or bonding time. Prevent by applying even pressure and curing for the recommended time.

- Cracks: Caused by excessive pressure or bonding temperature. Prevent by adjusting machine settings to suit the material.

- Delamination: Caused by poor surface preparation or incompatible adhesives. Prevent by cleaning and sanding the surfaces before bonding and using the correct adhesive.

- Discoloration: Caused by overheating or chemical reactions. Prevent by following the manufacturer’s instructions for bonding temperature and materials.

5. How do you maintain and troubleshoot a fiberglass bonding machine?

- Daily: Clean the machine and its components.

- Weekly: Inspect for loose or worn parts.

- Monthly: Lubricate moving parts.

- Troubleshooting: Diagnose issues using error codes or visual inspection. Common issues include pressure problems, temperature fluctuations, and electrical faults.

6. What are the different types of adhesives used in fiberglass bonding?

- Epoxy: Strong and durable, used for structural bonding.

- Polyester: Less expensive, used for non-structural bonding.

- Polyurethane: Flexible and resistant to environmental factors.

- Acrylic: Transparent and used for aesthetic bonding.

7. How do you determine the correct bonding parameters for a specific application?

- Consider the type of fiberglass material.

- Refer to the manufacturer’s recommendations for the adhesive.

- Experiment with different settings to optimize bond strength and quality.

8. What is the role of a quality control inspector in the fiberglass bonding process?

- Inspect incoming materials for defects.

- Verify bonding parameters and follow procedures.

- Test samples to ensure bond strength and quality.

- Identify and report any deviations or defects.

9. How do you handle hazardous materials associated with fiberglass bonding, such as solvents and adhesives?

- Wear appropriate personal protective equipment.

- Handle and store materials in a well-ventilated area.

- Dispose of waste materials in accordance with environmental regulations.

- Follow manufacturer’s guidelines for safe handling.

10. How do you stay up-to-date on the latest advancements in fiberglass bonding technology?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Engage with peers and experts in the field.

- Experiment with new techniques and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Bonding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Bonding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Bonding Machine Tenders operate specialized machinery to bond fiberglass materials, adhering to quality and production standards. They play a crucial role in the manufacturing process of various fiberglass products.

1. Fiberglass Bonding Process:

Operate fiberglass bonding machines to bond fiberglass materials using various techniques, including hand lay-up, vacuum bagging, and compression molding.

- Prepare and mix fiberglass materials, including resins, catalysts, and reinforcements.

- Apply fiberglass materials to molds or surfaces, ensuring even distribution and proper bonding.

2. Machine Operation and Maintenance:

Maintain and troubleshoot fiberglass bonding machinery, ensuring optimal performance and safety.

- Follow operating procedures and safety protocols for fiberglass bonding equipment.

- Perform routine maintenance tasks, such as cleaning, lubricating, and adjusting machines.

3. Quality Control:

Inspect bonded fiberglass products to ensure they meet specifications and quality standards.

- Examine products for defects, voids, or imperfections.

- Take corrective actions to address any quality issues identified.

4. Production Monitoring:

Monitor production processes to optimize efficiency and productivity.

- Track production progress and identify areas for improvement.

- Report any production issues or delays to supervisors.

Interview Tips

Preparing effectively for an interview can significantly increase your chances of success. Here are some crucial interview tips for Fiberglass Bonding Machine Tender candidates:

1. Research the Company and Role:

Familiarize yourself with the company’s background, industry, and the specific requirements of the Fiberglass Bonding Machine Tender position. This will help you demonstrate your interest and understanding of the role.

- Visit the company’s website and social media pages to gather information about their products, services, and culture.

- Thoroughly review the job description to identify the essential qualifications and responsibilities.

2. Practice Answering Common Interview Questions:

Anticipate potential interview questions and prepare your responses in advance. Practice answering questions related to your skills, experience, and knowledge of fiberglass bonding processes.

- Use the STAR method to structure your answers. Provide specific examples from your past experiences that highlight your relevant skills and abilities.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Showcase Your Technical Expertise:

Emphasize your technical knowledge and experience in fiberglass bonding. Highlight your proficiency in operating and maintaining fiberglass bonding machinery, as well as your understanding of the different bonding techniques.

- Provide examples of complex projects you have successfully completed, demonstrating your ability to handle challenging assignments.

- Discuss your knowledge of safety protocols and regulations related to fiberglass bonding operations.

4. Highlight Your Attention to Detail:

Fiberglass Bonding Machine Tenders must possess a keen eye for detail to ensure the accuracy and quality of bonded products. In your interview, emphasize your ability to identify and correct defects or imperfections.

- Describe your quality control procedures and the measures you take to ensure compliance with standards.

- Share examples of how you have resolved production issues or improved product quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Bonding Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!