Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Fabricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

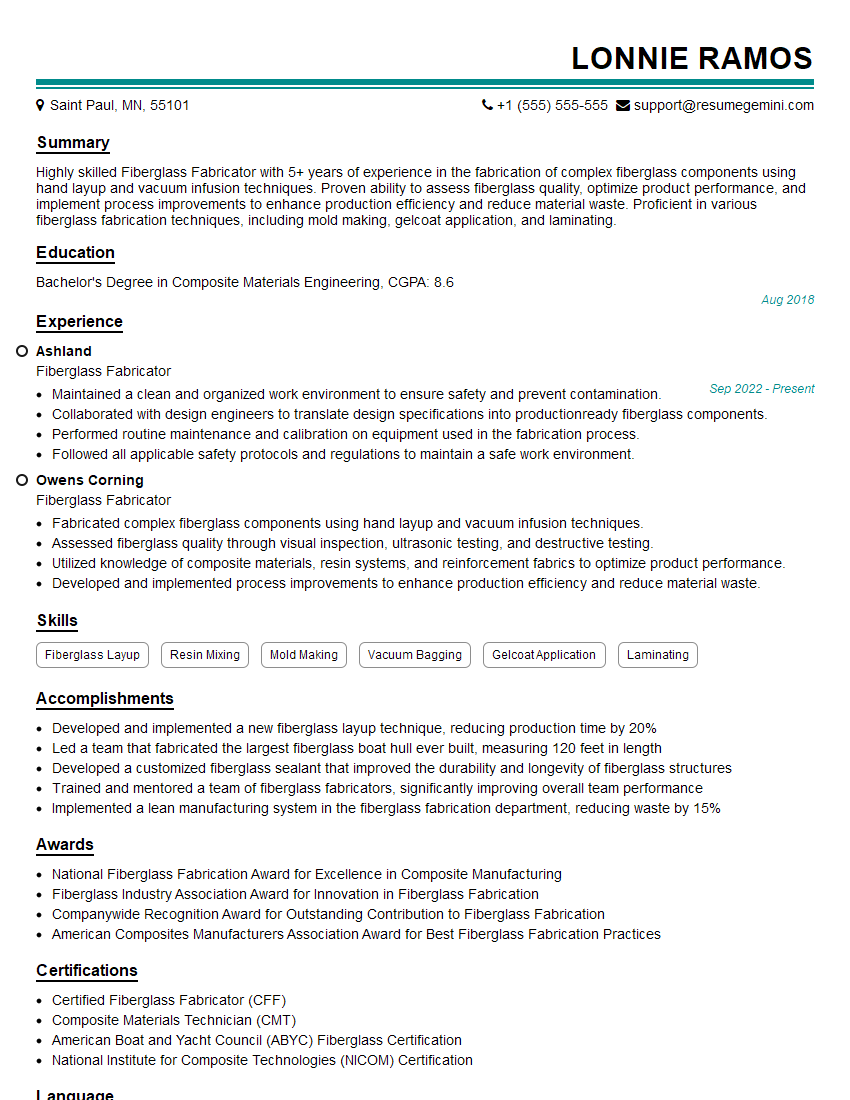

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Fabricator

1. Explain the different types of fiberglass materials used for fabrication and their properties?

- E-glass: Most common type, good strength, electrical insulation properties, chemical resistance.

- S-glass: Higher strength and modulus, used in aerospace, automotive applications.

- C-glass: High chemical resistance, used in corrosive environments.

- R-glass: High electrical resistance, used in electrical applications.

- Quartz: High temperature resistance, used in aerospace, military.

2. Describe the process of laying up a fiberglass laminate.

Layup steps:

Gelcoat:

- Applied first, provides a smooth surface finish.

Fiberglass Mat:

- Chopped fiberglass strands held together by a binder.

- Provides strength and thickness to the laminate.

Woven Roving:

- Continuous fiberglass strands woven together.

- Provides additional strength and stiffness.

Core Materials:

- Foam, balsa wood, or honeycomb, used to reduce weight and thickness.

Resin:

- Binds the fiberglass together, typically polyester, vinyl ester, or epoxy.

3. What are the different methods used to cure fiberglass laminates?

- Curing at room temperature: Takes longer, can be controlled using catalysts.

- Heat curing: Uses heat to accelerate curing, improves strength and properties.

- Elevated temperature curing: Cures at higher temperatures, provides the highest strength and properties.

4. How do you ensure the quality of a fiberglass laminate?

- Inspection: Examine the laminate for defects, voids, or delaminations.

- Testing: Conduct mechanical testing to measure strength, stiffness, and other properties.

- Non-destructive testing: Use techniques like ultrasonic testing or X-ray to detect internal defects.

5. What are some common challenges in fiberglass fabrication and how do you overcome them?

- Delaminations: Use proper adhesion techniques, eliminate air pockets.

- Voids: Ensure proper wetting out of fiberglass, remove excess air.

- Fiber orientation: Orient fibers optimally for desired strength and stiffness.

- Curing defects: Control curing conditions, use appropriate catalysts and accelerators.

6. Describe the different types of fiberglass molds used for fabrication.

- Open molds: Simple molds, allow easy access to the laminate.

- Closed molds: Enclose the laminate on all sides, provide a more uniform shape.

- Matched molds: Split into two halves, allow for complex shapes.

- Vacuum-assisted molds: Use vacuum to remove air and improve laminate quality.

7. How do you calculate the weight of a fiberglass laminate?

Formula:

Weight = (Density of fiberglass) x (Volume of laminate)8. What are the advantages and disadvantages of using fiberglass in fabrication?

Advantages:

- Lightweight and strong.

- Corrosion-resistant.

- Electrical insulator.

- Versatile and moldable.

Disadvantages:

- Brittle and can be damaged by impact.

- Combustible and can release toxic fumes when burning.

- Can be difficult to repair.

9. How do you select the appropriate type of resin for a fiberglass fabrication project?

Factors to consider:

- Strength and stiffness requirements.

- Environmental conditions (temperature, moisture, chemicals).

- Application and desired properties (flexibility, heat resistance, etc.).

10. Describe the process of post-curing fiberglass laminates and its benefits.

- Heating the laminate to a specific temperature after initial curing.

- Benefits: improves strength, stiffness, chemical resistance, and dimensional stability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Fabricators are responsible for creating and repairing fiberglass products. These products can include boats, pools, and other structures. They work with a variety of materials, including fiberglass, resin, and gelcoat. Fiberglass Fabricators use a variety of tools and techniques to create their products, including hand tools, power tools, and spray guns.

1. Fabricate Fiberglass Products

Fiberglass Fabricators create fiberglass products by following blueprints and specifications. They use a variety of materials, including fiberglass, resin, and gelcoat. They use a variety of tools and techniques to create their products, including hand tools, power tools, and spray guns.

2. Repair Fiberglass Products

Fiberglass Fabricators repair fiberglass products that have been damaged. They use a variety of techniques to repair damage, including patching, bonding, and laminating. They also use a variety of tools and materials to repair damage, including fiberglass, resin, and gelcoat.

3. Maintain Fiberglass Products

Fiberglass Fabricators maintain fiberglass products to keep them in good condition. They clean, polish, and wax fiberglass products to protect them from the elements. They also inspect fiberglass products for damage and make repairs as needed.

4. Work with Customers

Fiberglass Fabricators work with customers to discuss their needs and to provide them with estimates for their projects. They also answer questions about fiberglass products and their maintenance.

Interview Tips

Preparing for an interview can be daunting, but with a little planning and practice, you can increase your chances of success significantly. Here are a few tips to help you prepare:

1. Research the Company

Before you go to an interview, it is important to research the company. This will help you learn about the company’s culture, values, and products or services. You can research the company on their website, social media pages, and by reading news articles about the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture. You should also make sure to arrive on time for your interview.

4. Be Yourself

Interviews are a chance for you to show the interviewer who you are and why you are the best person for the job. It is important to be yourself and to let your personality shine through.

5. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your chance to learn more about the company and the position. It is also a good opportunity to show the interviewer that you are interested in the job and that you have done your research.

Next Step:

Now that you’re armed with the knowledge of Fiberglass Fabricator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fiberglass Fabricator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini