Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

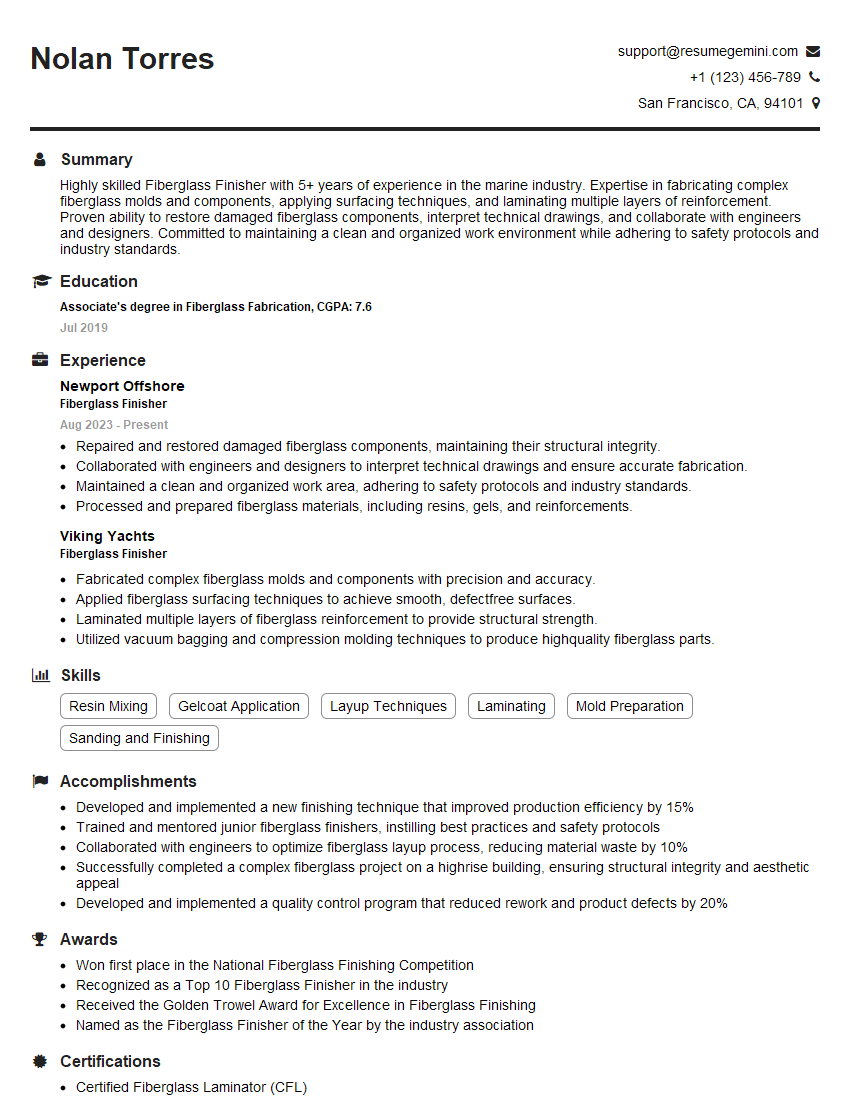

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Finisher

1. What are the different types of fiberglass materials and their applications?

- Chopped strand mat (CSM) is a non-woven mat made of short, randomly oriented fiberglass strands. It is used in a variety of applications, including boat hulls, car parts, and wind turbine blades.

- Woven roving is a fabric made of continuous fiberglass strands that are woven together. It is stronger than CSM and is used in applications where strength is important, such as aircraft parts and pressure vessels.

- Fabricated fiberglass is made by combining fiberglass with other materials, such as resin, gelcoat, and core materials. It is used in a variety of applications, including boat hulls, swimming pools, and shower stalls.

2. What are the different techniques used to finish fiberglass surfaces?

Sanding

- Sanding is the most common method of finishing fiberglass surfaces. It can be done by hand or with a power sander.

- Sanding can be used to remove imperfections, smooth the surface, and create a desired texture.

Buffing

- Buffing is a process of using a polishing compound and a buffer to bring out the shine of a fiberglass surface.

- Buffing can be done by hand or with a power buffer.

Wet sanding

- Wet sanding is a process of sanding fiberglass surfaces while they are wet. This helps to prevent the fiberglass dust from getting into the air and reduces the risk of respiratory problems.

- Wet sanding can also help to produce a smoother finish.

3. What are the different types of coatings that can be applied to fiberglass surfaces?

- Gelcoat is a pigmented resin that is applied to the surface of fiberglass to provide a smooth, glossy finish.

- Paint is a pigmented liquid that is applied to the surface of fiberglass to provide color and protection.

- Varnish is a clear liquid that is applied to the surface of fiberglass to provide protection and a glossy finish.

4. What are the different safety precautions that should be taken when working with fiberglass?

- Wear a respirator to protect your lungs from fiberglass dust.

- Wear gloves to protect your skin from fiberglass splinters.

- Wear eye protection to protect your eyes from fiberglass particles.

- Work in a well-ventilated area to prevent fiberglass dust from accumulating in the air.

- Dispose of fiberglass waste properly to prevent it from contaminating the environment.

5. What are the different tools and equipment that are used by fiberglass finishers?

- Sandpaper is used to sand fiberglass surfaces smooth.

- Buffing pads are used to buff fiberglass surfaces to a high shine.

- Resin is used to bond fiberglass together.

- Gelcoat is used to create a smooth, glossy finish on fiberglass surfaces.

- Paint is used to add color and protection to fiberglass surfaces.

- Varnish is used to protect fiberglass surfaces and give them a glossy finish.

6. What are the different skills and knowledge that are required to be a successful fiberglass finisher?

- Knowledge of fiberglass materials and their applications

- Knowledge of fiberglass finishing techniques

- Knowledge of different types of coatings that can be applied to fiberglass surfaces

- Knowledge of different safety precautions that should be taken when working with fiberglass

- Skills in using different tools and equipment used by fiberglass finishers

- Ability to work independently and as part of a team

- Ability to follow instructions and meet deadlines

7. What are the different challenges that fiberglass finishers face?

- Fiberglass dust can be harmful to your lungs if inhaled.

- Fiberglass splinters can be sharp and painful.

- Fiberglass surfaces can be slippery and difficult to work on.

- Fiberglass is a flammable material.

- Fiberglass waste can be difficult to dispose of.

8. What are the different opportunities for advancement for fiberglass finishers?

- Fiberglass finishers can advance to positions such as fiberglass fabricators, fiberglass supervisors, and fiberglass managers.

- Fiberglass finishers can also start their own businesses.

9. What are the different ways to stay up-to-date on the latest fiberglass finishing techniques?

- Attend fiberglass finishing workshops and conferences.

- Read fiberglass finishing trade magazines and articles.

- Join fiberglass finishing online forums and discussion groups.

10. What are the different ways to improve your skills as a fiberglass finisher?

- Practice fiberglass finishing techniques on your own time.

- Take fiberglass finishing courses at a local community college or trade school.

- Work as an apprentice under an experienced fiberglass finisher.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Finishers, also known as Gelcoat Finishers, are skilled workers who specialize in the final stages of fiberglass fabrication and repair. They apply a smooth, decorative, and protective finish to fiberglass surfaces using gelcoat, a specialized type of resin.

1. Surface Preparation

Prepare fiberglass surfaces for gelcoating, including cleaning, sanding, and filling any imperfections.

- Remove dust, dirt, and grease from the surface.

- Sand the surface to create a smooth, even finish.

- Fill any holes or imperfections with a suitable filler.

2. Gelcoat Application

Apply gelcoat to the prepared surface, using a variety of techniques such as spraying, rolling, or brushing.

- Mix and prepare the gelcoat according to manufacturer’s instructions.

- Apply the gelcoat evenly and smoothly to achieve a uniform thickness.

- Control the curing time and temperature to ensure proper adhesion and hardening.

3. Finishing and Polishing

Finish and polish the gelcoat surface to achieve the desired appearance and properties.

- Remove any excess gelcoat or imperfections using sanding and polishing techniques.

- Buff and wax the surface to create a glossy, protective finish.

- Ensure that the finished surface meets the required aesthetic and functional specifications.

4. Quality Control

Inspect and ensure the quality of the finished fiberglass surfaces.

- Check the surface for smoothness, uniformity, color accuracy, and any defects.

- Perform testing and measurements to verify that the surface meets specified standards.

- Document and report any quality issues or deviations.

Interview Tips

Preparing for a Fiberglass Finisher interview requires a combination of technical knowledge and an understanding of the industry.

1. Research the Company and Industry

Learn about the company’s products, services, and reputation in the fiberglass industry.

- Visit the company website, read news articles, and check online reviews.

- Research industry trends, innovations, and best practices.

2. Prepare for Technical Questions

Review your knowledge of fiberglass materials, fabrication techniques, and industry standards.

- Prepare to discuss different types of fiberglass, gelcoats, and their properties.

- Explain the steps involved in fiberglass finishing, including surface preparation, gelcoat application, and polishing.

3. Highlight Your Skills and Experience

Emphasize your proficiency in fiberglass finishing techniques and your attention to detail.

- Quantify your accomplishments, using specific examples of projects you have worked on.

- Describe your ability to troubleshoot and solve problems in the fiberglass finishing process.

4. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in fiberglass finishing.

- What are the different types of gelcoats and their applications?

- How do you ensure the quality and durability of your finished surfaces?

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer about the role, company, and industry.

- Inquire about the specific projects or products you will be working on.

- Ask about the company’s commitment to quality and innovation.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fiberglass Finisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.