Are you gearing up for an interview for a Fiberglass Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fiberglass Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

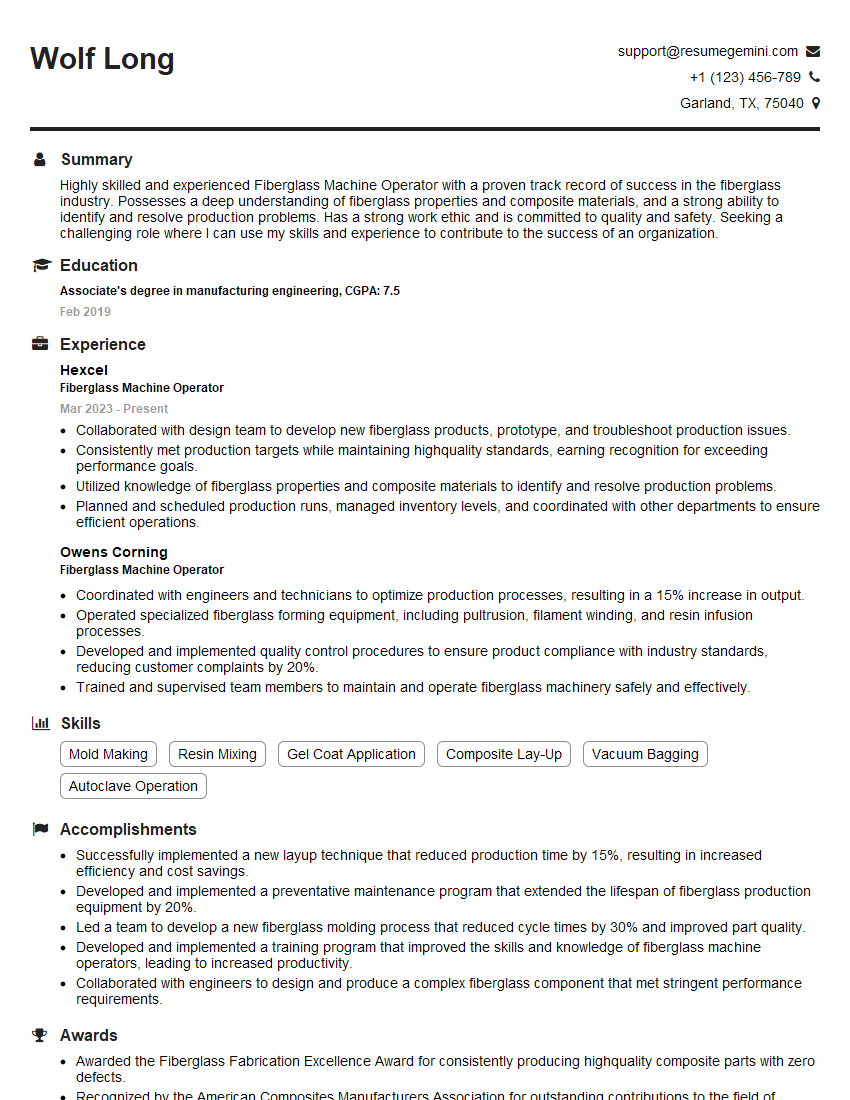

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Machine Operator

1. Describe the different types of fiberglass materials and their properties?

- Continuous fiberglass strands: Provides high tensile strength and stiffness, commonly used in structural applications.

- Chopped fiberglass strands: Shorter and randomly oriented, used for reinforcement in molding and composite materials.

- Fiberglass mats: Layers of chopped fiberglass strands bonded together, used in laminates and roofing applications.

- Fiberglass fabrics: Woven or knitted fiberglass materials, used for flexible and lightweight reinforcement.

- Fiberglass veil: Thin and lightweight material used for surface reinforcement and improving the appearance of fiberglass products.

2. Explain the process of operating a fiberglass production machine?

Resin Mixing and Delivery

- Prepare and mix the appropriate type and amount of resin.

- Control the delivery of the resin to the applicator.

Fiberglass Application

- Operate the machine to apply fiberglass strands, mats, or fabrics to the mold.

- Ensure proper coverage and orientation of the fiberglass material.

Curing and Demolding

- Monitor the curing process and adjust temperature and pressure as needed.

- Demold the finished fiberglass product once it has cured.

3. What are some common defects that can occur in fiberglass products and how do you prevent them?

- Blisters: Caused by trapped air or moisture, preventable by proper vacuum bagging and degassing.

- Delamination: Separation of layers, preventable by ensuring proper adhesion and surface preparation.

- Cracks: Caused by stress or impact, preventable by using appropriate reinforcements and avoiding excessive loads.

- Voids: Air pockets within the fiberglass, preventable by thorough compaction and vacuum bagging.

- Gelcoat imperfections: Surface defects resulting from improper application or curing, preventable by following manufacturer’s instructions and using high-quality materials.

4. How do you ensure the quality of fiberglass products?

- Regular machine calibration and maintenance.

- Inspection of raw materials and finished products.

- Testing for strength, stiffness, and durability.

- Adherence to industry standards and specifications.

- Continuous improvement and process optimization.

5. What is the importance of safety when operating fiberglass production machines?

- Wearing appropriate protective gear to prevent exposure to fiberglass dust and fumes.

- Following machine safety protocols and guarding hazardous areas.

- Handling and storing hazardous materials, such as resins, safely and according to regulations.

- Being aware of potential hazards, such as electrical shocks and moving machinery.

- Regularly receiving safety training and updates.

6. What are some advanced techniques used in fiberglass production?

- Prepreg and infusion molding: Automated processes for high-volume production.

- Vacuum-assisted resin transfer molding (VARTM): Improved resin distribution and reduced defects.

- Pultrusion: Continuous production of fiberglass profiles with high strength-to-weight ratios.

- Automated fiber placement (AFP): Laying down fiberglass strands precisely for complex shapes.

- Nanocomposites: Incorporating nanomaterials to enhance properties, such as strength and durability.

7. How do you stay up-to-date with the latest advancements in fiberglass technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Networking with other fiberglass professionals.

- Continuing education and training programs.

8. Describe your experience with different types of fiberglass production equipment?

- Gelcoat sprayers and applicators.

- Fiberglass chopper guns.

- Vacuum bagging equipment.

- Ovens and curing chambers.

- Automated production lines.

9. How do you handle troubleshooting and resolving production issues related to fiberglass machines?

- Identify the problem by analyzing symptoms and error messages.

- Refer to technical manuals and consult with experienced colleagues.

- Inspect and test machine components, such as pumps, valves, and sensors.

- Repair or replace defective parts as needed.

- Calibrate and adjust machine parameters to optimize performance.

10. What are your strengths and weaknesses as a fiberglass machine operator?

Strengths

- Extensive experience operating various fiberglass production machines.

- Strong knowledge of fiberglass materials and their properties.

- Excellent attention to detail and quality assurance practices.

- Ability to troubleshoot and resolve production problems effectively.

Weaknesses

- Limited experience with advanced fiberglass technologies, such as AFP and nanocomposites.

- Need to improve my understanding of automated production line operations.

11. What are your career goals and how does this role fit into them?

My career goal is to become a highly skilled and experienced fiberglass production manager. I believe that this role provides me with an excellent opportunity to develop my skills in operating and troubleshooting fiberglass machines and to gain a comprehensive understanding of the fiberglass production process. I am confident that I can contribute to the company’s success by optimizing production efficiency, maintaining high-quality standards, and staying up-to-date with the latest advancements in the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Machine Operators are responsible for operating and maintaining fiberglass production machines. They ensure that the machines are running smoothly and efficiently, and that the fiberglass products are produced according to specifications.

1. Operate Fiberglass Production Machines

This involves:

- Loading raw materials into the machine

- Starting and stopping the machine

- Monitoring the machine’s operation

- Making adjustments to the machine as needed

2. Inspect Fiberglass Products

This involves:

- Checking the products for defects

- Measuring the products to ensure they meet specifications

- Sorting the products into different grades

3. Maintain Fiberglass Production Machines

This involves:

- Cleaning the machines

- Lubricating the machines

- Replacing worn parts

- Troubleshooting machine problems

4. Follow Safety Procedures

This involves:

- Wearing appropriate safety gear

- Following all safety protocols

- Reporting any unsafe conditions to a supervisor

- Participating in safety training

Interview Tips

Preparing for an interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your Fiberglass Machine Operator interview:

1. Research the Company and the Position

Before you go into an interview, it’s important to do your research. This will help you understand the company’s culture, values, and goals. It will also help you learn more about the specific position you’re applying for. You can research the company’s website, LinkedIn page, and Glassdoor reviews. You can also read industry publications and articles to learn more about the fiberglass industry.

2. Practice Answering Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your responses confidently and concisely. You can also prepare for specific questions related to the fiberglass industry, such as “What is your experience with fiberglass production?” or “How do you troubleshoot fiberglass machine problems?”

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also arrive on time for your interview. Punctuality shows that you’re respectful of the interviewer’s time and that you’re serious about the position.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about their work. When you’re interviewing for a Fiberglass Machine Operator position, be sure to convey your passion for the industry and your eagerness to learn more. You should also be positive about your skills and abilities, and you should be able to articulate why you’re the best candidate for the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fiberglass Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fiberglass Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.