Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fiberglass Pipe Covering Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fiberglass Pipe Covering Supervisor so you can tailor your answers to impress potential employers.

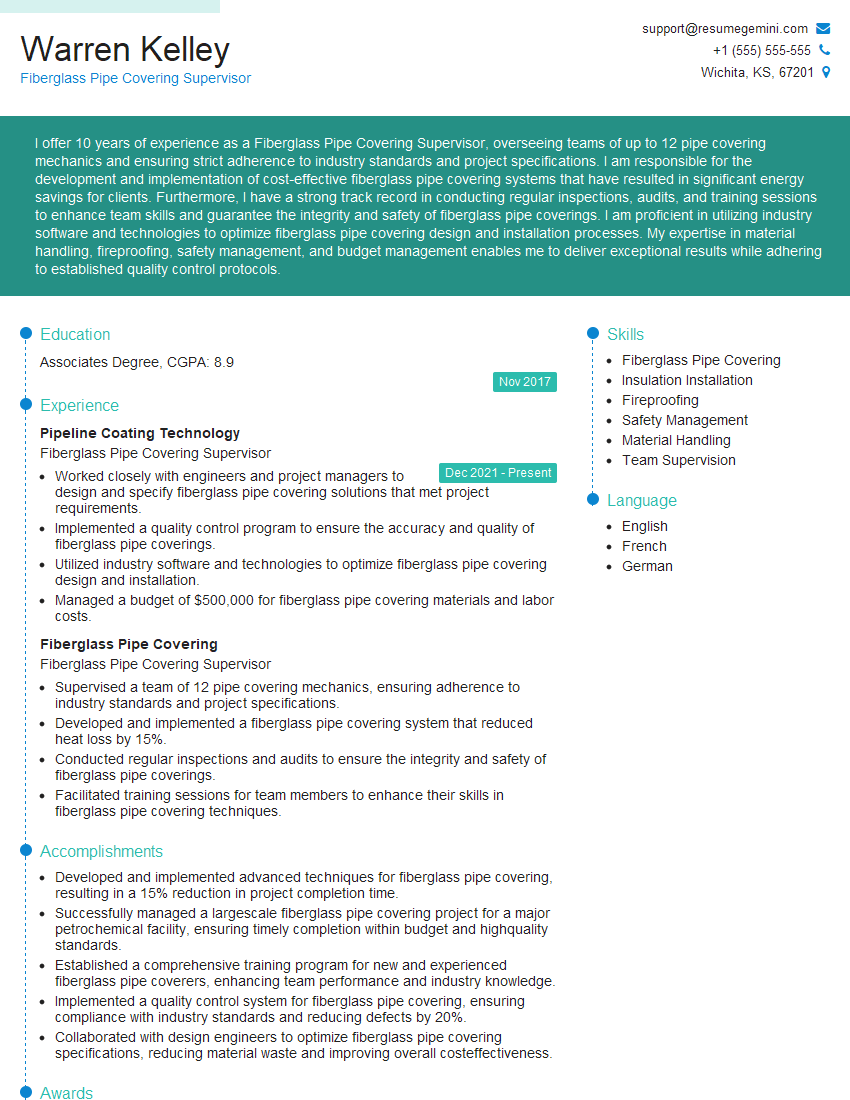

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Pipe Covering Supervisor

1. What are the key responsibilities of a Fiberglass Pipe Covering Supervisor?

- Overseeing and managing a team of fiberglass pipe covering installers

- Providing technical guidance and support to installers

- Inspecting and ensuring the quality of fiberglass pipe covering installations

- Developing and implementing safety procedures for fiberglass pipe covering installation

- Coordinating with other trades and disciplines involved in the construction process

2. What types of fiberglass insulation materials are commonly used and what are their respective advantages and disadvantages?

Closed-cell foam insulation

- Advantages: Excellent thermal resistance, moisture resistance, durability

- Disadvantages: More expensive than other types of insulation, can be difficult to install

Open-cell foam insulation

- Advantages: Less expensive than closed-cell foam, easier to install

- Disadvantages: Lower thermal resistance, less moisture resistant

Mineral wool insulation

- Advantages: Fire resistant, non-combustible, durable

- Disadvantages: Can be irritating to the skin and lungs, can absorb moisture

3. What are the different methods of applying fiberglass pipe covering and what are the advantages and disadvantages of each method?

Spray-on application

- Advantages: Fast and efficient, provides a seamless coating

- Disadvantages: Can be messy, requires specialized equipment

Wrap-and-tape application

- Advantages: Less expensive than spray-on application, easier to repair

- Disadvantages: More time-consuming, may not provide as seamless a coating

Molded application

- Advantages: Provides a highly durable and protective coating, can be customized to fit any shape

- Disadvantages: More expensive than other methods, can be time-consuming to install

4. What are the key safety considerations when working with fiberglass pipe covering materials?

- Wear appropriate personal protective equipment, including gloves, respirators, and eye protection

- Avoid contact with skin and eyes

- Do not inhale fiberglass dust

- Keep work areas well-ventilated

- Dispose of fiberglass waste properly

5. What are the common problems that can occur during fiberglass pipe covering installation and how can they be prevented?

Air leaks

- Causes: Improper installation, damage to the covering

- Prevention: Inspect the covering for any gaps or tears, seal any leaks with tape or mastic

Condensation

- Causes: Moisture penetration through the covering

- Prevention: Install a vapor barrier between the pipe and the covering, ensure the covering is properly sealed

Corrosion

- Causes: Exposure to moisture, chemicals, or other corrosive substances

- Prevention: Apply a protective coating to the covering, inspect the covering regularly for any signs of corrosion

6. How do you ensure that fiberglass pipe covering installations meet all applicable codes and standards?

- Review the project specifications and ensure that the covering meets the required thickness, density, and fire resistance rating

- Inspect the covering regularly to ensure that it is installed correctly and is in good condition

- Work with a qualified inspector to ensure that the installation meets all applicable codes and standards

7. What are the key skills and qualities that make a successful Fiberglass Pipe Covering Supervisor?

- Strong technical knowledge of fiberglass pipe covering materials and installation methods

- Excellent supervisory and leadership skills

- Ability to work independently and as part of a team

- Excellent communication and interpersonal skills

- Commitment to safety and quality

8. Describe a challenging project that you have worked on as a Fiberglass Pipe Covering Supervisor and how you overcame the challenges.

I recently worked on a large-scale project involving the installation of fiberglass pipe covering on a complex piping system. The project was challenging due to the tight deadlines and the need to work around other trades. I overcame these challenges by working closely with the project manager and other trades to coordinate our schedules. I also developed a detailed installation plan and assigned qualified installers to each task. As a result, we were able to complete the project on time and within budget.

9. What are your career goals and how do you see this position helping you achieve those goals?

My career goal is to become a project manager in the construction industry. I believe that this position as a Fiberglass Pipe Covering Supervisor will provide me with the necessary skills and experience to achieve my goal. This position will allow me to develop my leadership skills, learn about the construction process, and gain experience in managing a team of workers. I am confident that I can make a valuable contribution to your company and I am excited to learn more about this opportunity.

10. Do you have any questions for me about the position or the company?

I am very interested in this position and I am confident that I have the skills and experience to be successful in this role. I am eager to learn more about the company and the position. I am also interested in learning about the company’s culture and values. I believe that I would be a valuable asset to your team and I am excited about the opportunity to contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Pipe Covering Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Pipe Covering Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fiberglass Pipe Covering Supervisor is responsible for overseeing the installation and maintenance of fiberglass pipe coverings in various industrial and commercial settings. Their key responsibilities include:

1. Planning and Coordination

Planning and coordinating the installation and maintenance of fiberglass pipe coverings, including determining material requirements, scheduling labor, and ensuring compliance with safety regulations.

- Developing and implementing work plans for fiberglass pipe covering projects.

- Coordinating with project managers, engineers, and other contractors to ensure smooth execution of projects.

2. Supervision and Management

Supervising and managing a team of fiberglass pipe coverers, providing guidance, training, and performance evaluations.

- Hiring, training, and evaluating fiberglass pipe coverers.

- Ensuring that crew members follow proper safety procedures and adhere to company policies.

3. Quality Control and Inspection

Inspecting fiberglass pipe coverings to ensure they meet specifications and industry standards, addressing any discrepancies promptly.

- Conducting regular inspections of fiberglass pipe coverings to assess their condition and identify any potential issues.

- Working with quality control personnel to ensure that all fiberglass pipe coverings meet the required standards.

4. Safety and Compliance

Ensuring compliance with all relevant safety regulations and industry best practices, maintaining a safe work environment.

- Developing and implementing safety procedures for fiberglass pipe covering operations.

- Training crew members on safety protocols and ensuring they wear appropriate personal protective equipment.

Interview Tips

To ace your interview for a Fiberglass Pipe Covering Supervisor position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific requirements of the Fiberglass Pipe Covering Supervisor role. This will help you understand the company’s needs and demonstrate your interest in the position.

- Visit the company’s website and LinkedIn page to gather information about their business and culture.

- Read job descriptions and industry publications to gain insights into the responsibilities and expectations of the role.

2. Highlight Relevant Experience and Skills

In your resume and interview responses, emphasize your experience and skills that are directly relevant to the job requirements. Quantify your accomplishments whenever possible to provide tangible evidence of your contributions.

- Describe your experience in planning, coordinating, and supervising fiberglass pipe covering projects.

- Provide examples of how you have ensured compliance with safety regulations and maintained a safe work environment.

3. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and career goals. Practice answering these questions concisely and effectively, highlighting your strengths and how they align with the job requirements.

- Why are you interested in this Fiberglass Pipe Covering Supervisor position?

- Describe your experience in managing and motivating a team.

- How do you ensure the quality and safety of fiberglass pipe covering installations?

4. Ask Informed Questions

Asking insightful questions during the interview demonstrates your interest and engagement. Prepare questions that show you have researched the company and the role, and that you are eager to learn more about the organization and the position.

- What are the company’s current and future plans for fiberglass pipe covering projects?

- What opportunities are there for professional development and advancement within the company?

5. Showcase Your Communication Skills

Throughout the interview, pay attention to your communication skills. Speak clearly and confidently, using appropriate industry terminology. Listen attentively to the interviewer’s questions and respond in a professional and organized manner.

- Maintain eye contact and use positive body language to convey enthusiasm and engagement.

- Use specific examples and anecdotes to illustrate your points and demonstrate your expertise.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Pipe Covering Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!