Are you gearing up for an interview for a Fiberglass Quality Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fiberglass Quality Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

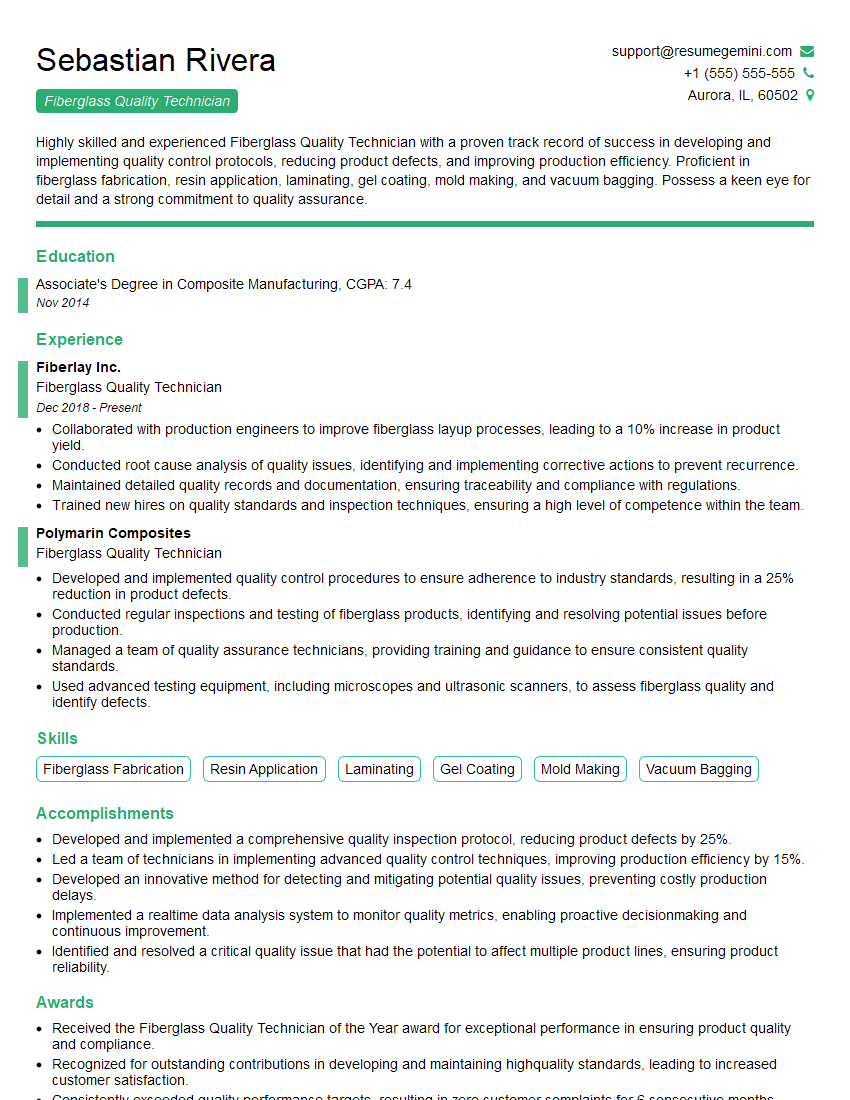

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Quality Technician

1. Describe the key steps involved in the production of Fiberglass Reinforced Plastics (FRP)?

- Creating a mold or form for the desired FRP product.

- Applying layers of fiberglass reinforcement to the mold.

- Saturating each layer of fiberglass with an appropriate type of resin.

- Compressing the layers together under heat and pressure until fully cured.

2. Explain the importance of proper resin mixing ratio and how it affects the quality of FRP?

- Incorrect mixing ratio can affect the fiber-to-resin ratio, resulting in insufficient strength or durability.

- Excess of resin can lead to a weak and brittle product, while excess of fiber can make the mix too viscous and difficult to handle.

- Following the manufacturer’s specified ratio is crucial for optimal properties and performance.

3. What testing methods are used to determine the quality of FRP products?

- Visual inspection for surface defects, cracks, or delamination.

- Mechanical testing such as tensile, flexural, and impact tests to evaluate strength and durability.

- Nondestructive testing (NDT) methods like ultrasonic or radiographic testing to detect internal flaws or voids.

4. How do you identify and mitigate common defects found in FRP products?

- Air pockets or voids: Degas the resin and use proper vacuum techniques during layup.

- Fiber misalignment: Ensure proper alignment and use perforated release films.

- Cracks: Control exothermic reactions during curing, use appropriate release agents, and avoid sudden temperature changes.

5. Explain the role of ultraviolet (UV) stabilizers in FRP and how their selection impact product durability?

- UV stabilizers protect FRP from the damaging effects of sunlight.

- Different types of UV stabilizers provide varying levels of protection and are selected based on the intended application and exposure conditions.

- Choosing the right UV stabilizers helps extend the product’s lifespan and maintain its structural integrity.

6. Describe the different types of Fiberglass reinforcements and their properties?

- E-glass: General-purpose, economical, and offers good mechanical properties.

- S-glass: High strength-to-weight ratio, excellent corrosion resistance, and used in high-performance applications.

- Carbon fiber: Lightweight, high-strength, and used in specialty applications like aerospace.

7. How do you optimize the layup schedule for complex FRP molds to ensure strength and quality?

- Analyze the part geometry and loading conditions.

- Determine the ply thickness and orientation to meet structural requirements.

- Consider factors such as resin curing time, fiber-to-resin ratio, and surface finish.

8. What are the industry standards and quality control procedures for FRP fabrication?

- ISO 2577: Standard for glass-reinforced plastics (GRP) laminates.

- ASTM D3518: Standard for reinforced thermosetting plastics (RTP).

- Regular inspections, testing, and documentation to meet quality specifications.

9. How do you stay updated with the latest advancements and best practices in FRP technology?

- Attend industry conferences, workshops, and training programs.

- Read technical journals, research papers, and industry publications.

- Collaborate with peers and manufacturers to share knowledge and stay informed.

10. What is the role of quality control in maintaining consistent product quality in FRP manufacturing?

- Establishing clear quality standards and specifications.

- Implementing inspection and testing procedures throughout the production process.

- Identifying and correcting any deviations from quality standards.

- Maintaining documentation and records for quality assurance purposes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Quality Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Quality Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fiberglass Quality Technician ensures that fiberglass products meet specified quality standards, from raw materials to finished products. Their daily tasks:

1. Inspection and Testing

Inspect raw materials such as resins, fibers, and reinforcements for compliance with specifications.

- Conduct tests on finished products to evaluate strength, durability, and appearance.

2. Monitoring and Data Analysis

Monitor production processes to identify and resolve quality issues.

- Analyze data to determine trends and identify areas for improvement.

3. Documentation and Reporting

Maintain detailed records of inspections, tests, and corrective actions.

- Prepare reports summarizing quality performance and identifying opportunities for improvement.

4. Process Improvement

Participate in continuous improvement initiatives to enhance product quality and efficiency.

- Recommend process modifications and equipment upgrades to improve quality outcomes.

Interview Tips

Preparing for a Fiberglass Quality Technician interview requires a combination of technical knowledge and soft skills.

1. Research the Company and Role

Familiarize yourself with the company’s fiberglass products, quality standards, and industry trends.

- Review the job description thoroughly to identify specific responsibilities and requirements.

2. Highlight Your Technical Skills

Demonstrate your proficiency in fiberglass inspection techniques, testing equipment, and quality control principles.

- Quantify your experience in conducting inspections, analyzing data, and implementing corrective actions.

3. Showcase Your Problem-Solving Abilities

Provide examples of how you identified and resolved quality issues in previous roles.

- Explain your approach to investigating problems, developing solutions, and implementing improvements.

4. Emphasize Continuous Improvement Mindset

Highlight your commitment to ongoing learning and improvement in the field of quality control.

- Discuss your experience in implementing new technologies, developing innovative solutions, and participating in process optimization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Quality Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!