Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Roving Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

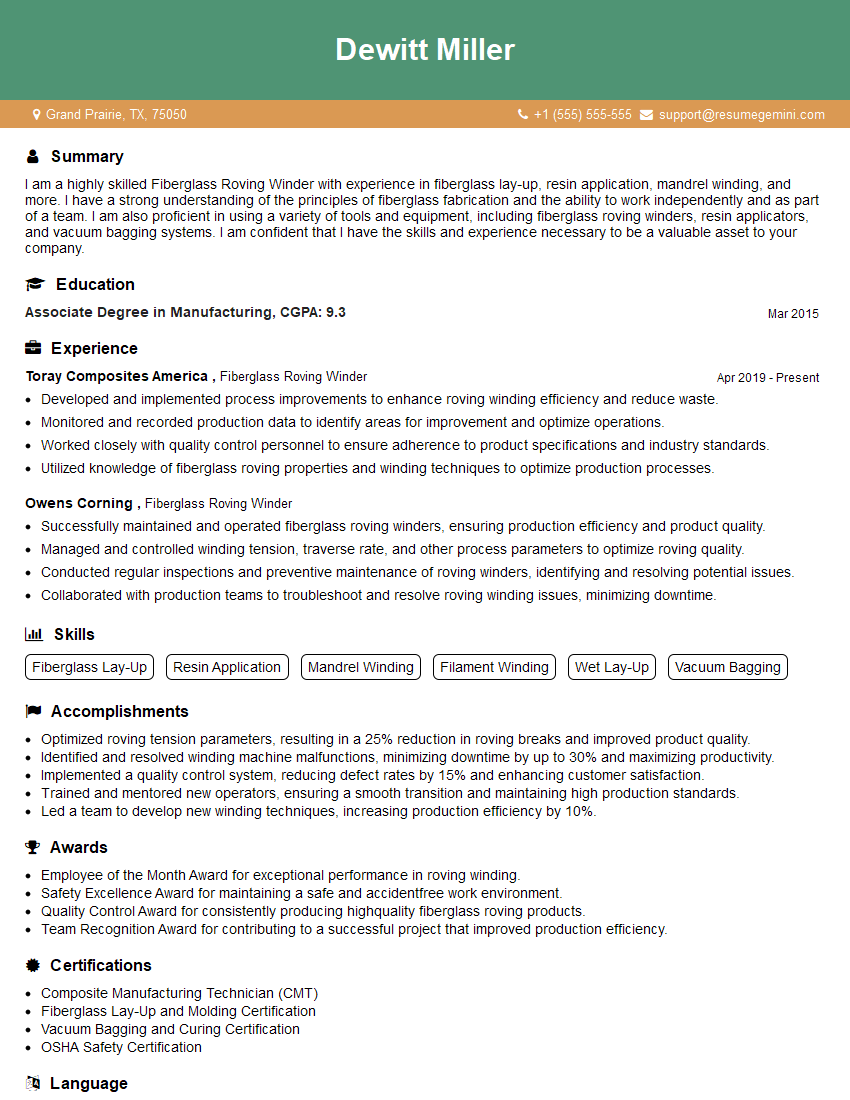

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Roving Winder

1. Explain the purpose and different types of fiberglass roving winders?

Fiberglass roving winders are machines used to wind fiberglass roving onto a bobbin or spool. There are various types of fiberglass roving winders, each designed for specific applications. These include:

- Horizontal roving winders

- Vertical roving winders

- Heavy-duty roving winders

- High-speed roving winders

2. Describe the process of winding fiberglass roving?

Tension Control

- Maintaining the correct tension during winding is crucial to ensure proper winding quality.

- Excessive tension can break the roving, while insufficient tension can lead to loose winding.

Traverse System

- The traverse system ensures that the roving is evenly distributed across the bobbin.

- Different traverse patterns, such as helical or cross-winding, can be used depending on the application.

Winding Speed

- The winding speed needs to be optimized to achieve efficient winding without compromising quality.

- Factors like roving type, bobbin size, and desired winding density influence the optimal winding speed.

3. What are the key parameters to consider when selecting the right fiberglass roving winder for a specific application?

- Roving type and size

- Bobbin or spool dimensions

- Desired winding density

- Production rate

- Available space and layout.

4. How do you ensure the quality of fiberglass roving winding?

- Inspecting roving prior to winding for any defects or damage.

- Calibrating and maintaining the winder to ensure precise tension control and winding parameters.

- Monitoring the winding process to detect any abnormalities or deviations.

- Performing regular maintenance and cleaning of the winder.

5. Describe the common troubleshooting techniques for fiberglass roving winders?

- Addressing tension issues by adjusting the tension settings or inspecting the tensioner.

- Fixing winding defects like overlapping or loose winding by adjusting the traverse system or winding speed.

- Resolving roving breakage by checking the roving quality or adjusting the tension.

- Troubleshooting electrical or mechanical problems by checking connections and inspecting components.

6. What are the safety precautions that should be observed when operating a fiberglass roving winder?

- Wearing appropriate protective gear, including gloves, safety glasses, and a mask.

- Ensuring the winder is properly grounded and electrically safe.

- Keeping the work area clean and free of tripping hazards.

- Following proper lifting techniques when handling bobbins or spools.

7. How do you stay updated with the latest advancements and best practices in fiberglass roving winding?

- Attending industry conferences and exhibitions.

- Reading technical journals and research papers.

- Seeking training and certification opportunities.

- Networking with other professionals in the field.

8. Explain the importance of maintenance and calibration for fiberglass roving winders?

Regular maintenance and calibration are crucial to ensure:

- Optimal performance and extended lifespan of the winder.

- Consistent winding quality and accuracy.

- Reduced downtime and production interruptions.

- Improved safety and reliability.

9. How do you handle situations where the fiberglass roving breaks during winding?

- Identify the cause of the breakage (e.g., tension issues, roving defects).

- Stop the winding process and clear the broken roving from the winder.

- Inspect the roving and winder components to determine the appropriate corrective action.

- Restart the winding process after resolving the issue and ensuring proper tension control.

10. Describe the different types of bobbins or spools used in fiberglass roving winding and their applications?

- Paper bobbins: Lightweight and economical, used for smaller roving packages.

- Plastic bobbins: Durable and resistant to moisture, suitable for larger roving packages.

- Metal spools: Heavy-duty and long-lasting, used for high-volume winding applications.

- Conical spools: Designed to facilitate smooth unwinding and prevent roving tangling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Roving Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Roving Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fiberglass Roving Winder is responsible for operating and maintaining fiberglass roving winding machines. These machines produce fiberglass roving, which is used in the production of fiberglass products such as insulation, pipes, and boats.

Job Duties:

The key job responsibilities of a Fiberglass Roving Winder include:

- Operate and maintain fiberglass roving winding machines

- Monitor the operation of the machines and make adjustments as needed

- Inspect the roving for defects and correct any problems

- Keep the work area clean and free of debris

- Follow safety procedures and wear appropriate personal protective equipment

- Perform other duties as assigned

Interview Tips

Preparing for an interview for a Fiberglass Roving Winder position can be stressful, but with the right strategies, you can increase your chances of success.

1. Research the company and position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Example:

If you are interviewing for a Fiberglass Roving Winder position at a manufacturing company, you might want to learn more about the company’s production process and quality control standards.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Example:

For the question “Why are you interested in this position?”, you might want to highlight your experience operating and maintaining fiberglass roving winding machines, as well as your knowledge of the industry.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as they relate to the job requirements. Be sure to highlight your relevant experience and skills in your resume and cover letter, and be prepared to talk about them in detail during your interview.

- Example:

If you have experience operating and maintaining fiberglass roving winding machines, be sure to mention this in your interview. You might also want to discuss any specific skills or knowledge that you have that would make you a valuable asset to the company.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as this shows that you are respectful of the interviewer’s time.

- Example:

For a Fiberglass Roving Winder position, you might want to wear clean, sturdy clothing that is appropriate for a manufacturing environment.

5. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and the company. Be sure to show your enthusiasm and positivity throughout the interview. This will help you make a good impression and increase your chances of getting the job.

- Example:

When the interviewer asks you why you are interested in the position, you might want to say something like, “I am excited about the opportunity to work for a leading manufacturer of fiberglass products. I am confident that my skills and experience would be a valuable asset to your team.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Roving Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.