Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Ski Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

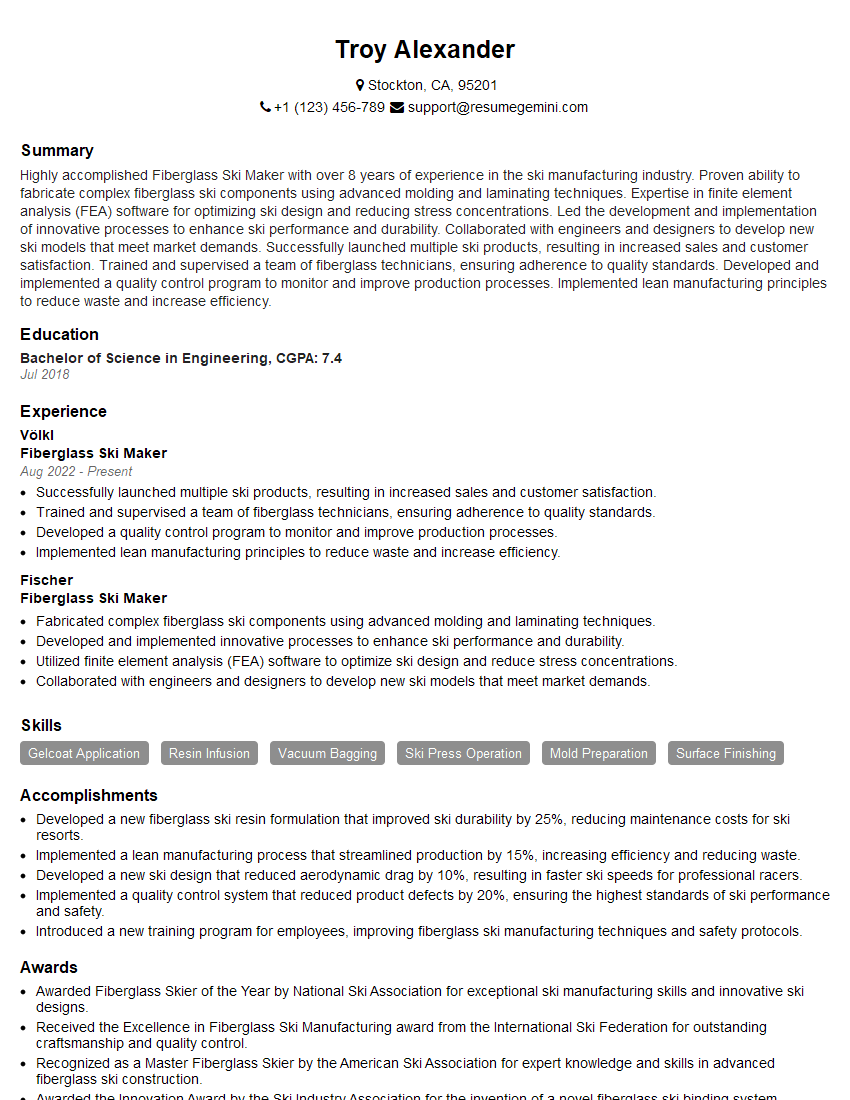

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Ski Maker

1. What are the key steps involved in the fiberglass ski making process?

The fiberglass ski making process involves several key steps:

- Core selection: Choosing the right core material, such as wood, foam, or a combination of materials, based on desired performance characteristics.

- Mold preparation: Preparing the ski mold by applying a release agent and positioning the core material inside.

- Layup: Applying layers of fiberglass cloth to the core, using different orientations and weights to achieve desired flex and strength.

- Vacuum bagging: Placing the laid-up ski in a vacuum bag to remove excess air and ensure proper resin distribution.

- Resin infusion: Injecting epoxy resin into the vacuum bag, allowing it to saturate the fiberglass layers and cure.

- Trimming and finishing: Once the resin has cured, the ski is trimmed to its final shape, edges are sharpened, and a base is applied.

2. What factors influence the performance characteristics of a fiberglass ski?

Materials:

- Core material: Wood provides natural flex and vibration damping, while foam is lighter and stiffer.

- Fiberglass type and orientation: Different types of fiberglass and their orientation affect the ski’s flex, torsional rigidity, and strength.

- Resin type: Epoxy resin provides excellent bonding strength and stiffness.

Design:

- Ski shape: The overall shape, including tip and tail width, camber, and sidecut, determines the ski’s turning ability and stability.

- Flex pattern: The distribution of flex throughout the ski, from tip to tail, influences its responsiveness and handling characteristics.

3. How do you ensure the quality and durability of fiberglass skis?

To ensure quality and durability:

- Material selection: Using high-quality materials, such as aerospace-grade fiberglass and epoxy resin, to withstand stress and abuse.

- Precision layup: Carefully applying layers of fiberglass with the correct orientation and tension to achieve optimal strength and performance.

- Vacuum bagging: Removing excess air during resin infusion to prevent voids and ensure uniform resin distribution.

- Proper curing: Allowing the resin to cure at the optimal temperature and time to achieve maximum strength and durability.

- Rigorous testing: Conducting flex, torsional, and impact tests to verify ski performance and durability before releasing it for production.

4. What are the common challenges faced in fiberglass ski making, and how do you overcome them?

Common challenges include:

- Resin curing: Ensuring uniform resin distribution and curing to prevent delamination or weak spots.

- Fiber orientation: Achieving precise fiber orientation to optimize ski flex and strength.

- Vacuum bagging: Maintaining proper vacuum levels and preventing air leaks.

- Dimensional accuracy: Adhering to strict tolerances for ski shape and dimensions.

- Quality control: Implementing thorough inspection and testing procedures to identify and address any potential defects.

Overcoming challenges requires a combination of:

- Technical expertise: Understanding the science behind materials and processes.

- Attention to detail: Focus on precision and accuracy in every step.

- Problem-solving skills: Identifying and resolving issues as they arise.

- Continuous improvement: Regularly evaluating and refining processes to enhance quality and efficiency.

5. What is the role of computer-aided design (CAD) and computer-aided manufacturing (CAM) in fiberglass ski making?

CAD and CAM play crucial roles:

- CAD:

- Designing ski shapes and flex patterns.

- Creating precise 3D models for mold production.

- Simulating ski performance and identifying potential issues.

- CAM:

- Controlling CNC machines to cut molds and trim skis.

- Automating resin infusion and vacuum bagging processes.

- Improving production efficiency and reducing errors.

6. How do you stay up-to-date with the latest advancements in fiberglass ski technology?

To stay informed:

- Industry events and conferences: Attending trade shows and workshops to learn about new materials, techniques, and equipment.

- Technical publications and research papers: Reading articles and white papers on ski design, materials, and manufacturing processes.

- Collaboration with experts: Engaging with engineers, scientists, and other professionals in the field to exchange knowledge and ideas.

- Continuous education: Pursuing training programs and workshops to enhance skills and knowledge.

7. What is your approach to working as part of a team in fiberglass ski manufacturing?

In a team environment:

- Communication: Actively communicating with colleagues, sharing information, and seeking feedback.

- Collaboration: Working together to solve problems, share ideas, and achieve common goals.

- Respect: Valuing and respecting diverse perspectives and contributions.

- Flexibility: Adapting to changing priorities and taking on different roles as needed.

- Results-oriented: Focusing on achieving team objectives and delivering high-quality products.

8. How do you handle working under pressure and meeting deadlines in fiberglass ski production?

To manage pressure and deadlines:

- Prioritization: Setting priorities and focusing on the most critical tasks.

- Time management: Utilizing tools and techniques to schedule tasks and allocate time effectively.

- Delegation: Assigning tasks to teammates when appropriate.

- Stress management: Practicing relaxation techniques and maintaining a positive mindset.

- Communication: Regularly updating supervisors and colleagues on progress and any potential challenges.

9. What motivates you to work as a fiberglass ski maker?

Motivating factors:

- Passion for skiing and winter sports: Enjoying the opportunity to contribute to the industry and create skis that enhance the skiing experience.

- Technical challenge: Appreciating the complex and technical nature of fiberglass ski manufacturing.

- Craftsmanship: Taking pride in producing skis that are both functional and aesthetically pleasing.

- Innovation: Embracing the opportunity to explore new materials and techniques to advance ski design.

- Customer satisfaction: Aiming to create skis that meet the needs and expectations of skiers.

10. What are your career goals and aspirations as a fiberglass ski maker?

Career goals and aspirations:

- Technical mastery: Continuously improving skills and knowledge in fiberglass ski manufacturing.

- Product development: Contributing to the design and development of innovative and high-performance skis.

- Process improvement: Exploring ways to enhance efficiency and quality in the manufacturing process.

- Leadership: Advancing to supervisory or management roles to guide and inspire teams.

- Industry recognition: Establishing a reputation as a skilled and knowledgeable fiberglass ski maker.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Ski Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Ski Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Ski Makers play a pivotal role in the manufacturing of high-quality fiberglass skis. Their responsibilities encompass various aspects of the production process, ensuring the skis meet stringent specifications and deliver exceptional performance.

1. Mold Preparation

Prior to fiberglass layup, Fiberglass Ski Makers prepare the molds meticulously. This involves cleaning and waxing the molds to facilitate the smooth release of finished skis.

2. Material Cutting and Layering

They cut and lay fiberglass sheets precisely onto the molds, adhering to specified patterns and angles. Each layer is carefully applied to achieve the desired strength, stiffness, and flexibility.

3. Resin Application and Curing

Fiberglass Ski Makers apply resin to the fiberglass layers and use vacuum bagging or compression molding techniques to ensure proper consolidation and curing.

4. Trimming and Finishing

Once the skis have cured, they trim excess material and apply edge bindings and other hardware. These steps enhance the skis’ aesthetics and performance.

5. Quality Control

Fiberglass Ski Makers conduct rigorous quality inspections throughout the production process. They check for defects, measure dimensions, and ensure the skis meet prescribed standards.

Interview Tips

Preparation is crucial for a successful interview. Here are some tips to help candidates ace their interview for a Fiberglass Ski Maker position:

1. Research the Company and Industry

Candidates should familiarize themselves with the company’s history, products, and industry standing. This demonstrates their interest and enthusiasm for the opportunity.

2. Highlight Relevant Skills and Experience

Emphasizing previous experience in fiberglass fabrication, mold making, or composite materials is essential. Quantifying results and using specific examples to showcase their abilities will impress the interviewer.

3. Prepare for Technical Questions

Candidates may encounter questions about fiberglass lamination techniques, resin selection, and quality control procedures. Studying industry terminology and processes will enhance their credibility.

4. Show Passion and Enthusiasm

Expressing a genuine passion for skiing and a deep understanding of ski design will differentiate candidates. They can discuss different ski types, materials, and innovations in the industry.

5. Be Punctual and Professional

Punctuality and professional demeanor make a lasting impression. Candidates should arrive on time, dress appropriately, and maintain eye contact during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Ski Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!