Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Field Mechanical Meter Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

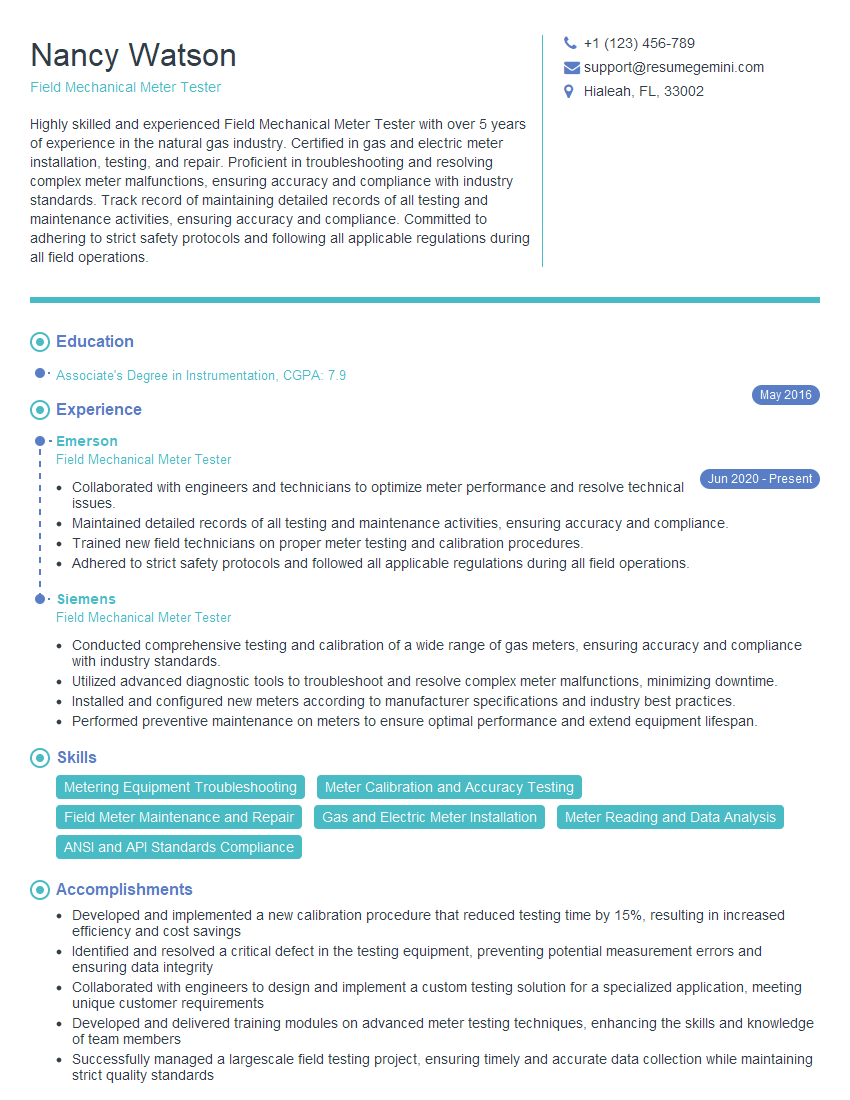

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Field Mechanical Meter Tester

1. Explain the process of calibrating a mechanical meter?

- I would first gather the necessary equipment, including a calibration standard, a pressure gauge, and a flowmeter.

- I would then disconnect the meter from the system and connect it to the calibration standard.

- I would use the pressure gauge to measure the pressure at the inlet and outlet of the meter, and the flowmeter to measure the flow rate.

- I would then adjust the meter’s calibration until the readings from the pressure gauge and flowmeter matched the readings from the calibration standard.

- I would finally reconnect the meter to the system and verify that it was operating properly.

2. What are the different types of mechanical meters?

Diaphragm Meters

- Operate on the principle of a flexible diaphragm that moves back and forth in proportion to the volume of gas flowing through the meter.

Rotary Meters

- Use a rotating element within the meter to measure the volume of gas flowing through.

Turbine Meters

- Employ a turbine that spins in proportion to the velocity of the gas flowing through the meter.

3. What are the most common problems that you encounter when testing mechanical meters?

- Clogged or dirty meters

- Damaged or worn diaphragms

- Leaking seals

- Incorrect calibration

4. What are the safety precautions that you must take when testing mechanical meters?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Ensure that the area where you are working is well-ventilated.

- Never smoke or use open flames near the meter.

- Be aware of the potential for gas leaks and take appropriate precautions.

5. What are the different methods for testing mechanical meters?

Bench Testing

- Involves removing the meter from the system and testing it on a bench.

In-Situ Testing

- Testing the meter while it is still installed in the system.

Non-Intrusive Testing

- Using ultrasonic or other non-invasive methods to test the meter without removing it from the system.

6. What are the different types of test equipment that you use to test mechanical meters?

- Calibration standards

- Pressure gauges

- Flowmeters

- Ultrasonic testers

- Non-intrusive testing devices

7. How do you interpret the results of a mechanical meter test?

- I would first compare the results of the test to the manufacturer’s specifications for the meter.

- I would then determine if the meter is operating within the acceptable tolerance range.

- If the meter is not operating within the acceptable tolerance range, I would recommend that it be repaired or replaced.

8. What are the benefits of regular mechanical meter testing?

- Ensures that the meter is operating accurately and reliably.

- Helps to identify potential problems early on, before they can cause major damage or downtime.

- Can help to save money by reducing the likelihood of overpaying for gas or other utilities.

9. What are the challenges of mechanical meter testing?

- Testing can be time-consuming and labor-intensive.

- It can be difficult to access meters that are located in difficult-to-reach locations.

- Testing can be hazardous, as it involves working with gas or other hazardous materials.

10. What is the future of mechanical meter testing?

- Non-intrusive testing is becoming increasingly popular, as it offers a faster, safer, and more cost-effective way to test meters.

- Automated testing systems are also being developed, which can further reduce the time and labor required to test meters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Field Mechanical Meter Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Field Mechanical Meter Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Field Mechanical Meter Testers play a crucial role in ensuring the accurate measurement and operation of energy meters. Their responsibilities encompass a wide range of tasks, including:

1. Meter Testing and Calibration

Conduct regular testing and calibration of mechanical energy meters to ensure they meet accuracy standards and industry regulations.

- Diagnose and troubleshoot any issues with meter performance, using specialized tools and equipment.

- Adjust and calibrate meters to ensure they provide accurate readings within specified tolerances.

2. Meter Installation and Removal

Install, remove, and replace mechanical energy meters at various locations, such as customer premises, substations, and distribution centers.

- Properly connect meters to the electrical system and ensure secure mounting.

- Maintain detailed records of all meter installations and removals, including dates, locations, and meter serial numbers.

3. Data Collection and Analysis

Collect and analyze data from energy meters to assess their performance and identify trends.

- Use data loggers or other devices to record energy consumption data over extended periods.

- Identify patterns, anomalies, and potential issues based on the collected data, and report findings.

4. Customer Support

Provide technical assistance and support to customers regarding energy meter-related issues.

- Respond to customer inquiries, diagnose problems, and provide solutions or recommendations.

- Maintain positive relationships with customers and address their concerns in a timely and professional manner.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some essential tips to help you ace your interview for a Field Mechanical Meter Tester position:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you’re applying for. Understand their business, industry, and culture.

- Visit the company’s website, read their LinkedIn page, and search for news articles or industry reports about them.

- Study the job description carefully and identify specific skills, experiences, and qualifications that the employer is looking for.

2. Practice and Prepare

Practice answering common interview questions and prepare examples that demonstrate your skills and experience. Consider using the STAR method to structure your answers:

- Situation: Describe a specific situation or task related to meter testing or calibration.

- Task: Explain your role and responsibilities in that situation.

- Action: Describe the steps you took to complete the task effectively.

- Result: Highlight the positive outcomes or results of your actions.

3. Emphasize Your Technical Skills

Field Mechanical Meter Testers need strong technical skills in electrical systems, meter testing equipment, and calibration procedures. Make sure to highlight your proficiency in these areas:

- Certifications or training in meter testing and calibration.

- Experience in using specialized tools and diagnostic equipment for meter troubleshooting.

- Knowledge of electrical safety protocols and regulations.

4. Highlight Your Customer Service Skills

Customer support is an essential aspect of this role. Emphasize your ability to communicate effectively, resolve issues, and maintain positive relationships with customers:

- Describe your experience in providing technical assistance and support to customers.

- Share examples of how you handled challenging situations or resolved complex customer inquiries.

- Demonstrate your empathy, patience, and willingness to go the extra mile for customers.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Maintain a positive and confident demeanor, and be prepared to ask thoughtful questions at the end of the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Field Mechanical Meter Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.